Buffing compounds play a vital role in achieving smooth, polished surfaces across various materials. These specialized abrasives remove imperfections, enhance shine, and create desired finishes. Selecting the right buffing compound ensures optimal results, whether working with metals, plastics, or wood. The global demand for these compounds reflects their importance, with the metal polishing compound market projected to grow from $7.4 billion in 2022 to $12.1 billion by 2032. This growth highlights their value in industries striving for cost-effective and high-quality surface finishing solutions.

Key Takeaways

- Buffing compounds are essential for achieving smooth, polished surfaces on various materials, including metals, plastics, and wood.

- Choosing the right buffing compound based on the material type and desired finish is crucial for optimal results.

- Cutting compounds like Black Emery are ideal for removing deep scratches, while polishing compounds like Rouge enhance shine without scratching delicate surfaces.

- Always match the buffing compound with the appropriate buffing wheel to ensure consistent performance and prevent uneven finishes.

- Proper application techniques, such as surface preparation and maintaining consistent motion, are key to achieving a professional-quality finish.

- Avoid common mistakes like using the wrong wheel or overloading the buffing wheel to ensure effective and safe buffing.

- Experimenting with different compounds and techniques can unlock new possibilities for achieving desired results in surface finishing.

Understanding Buffing Compounds

What Are Buffing Compounds?

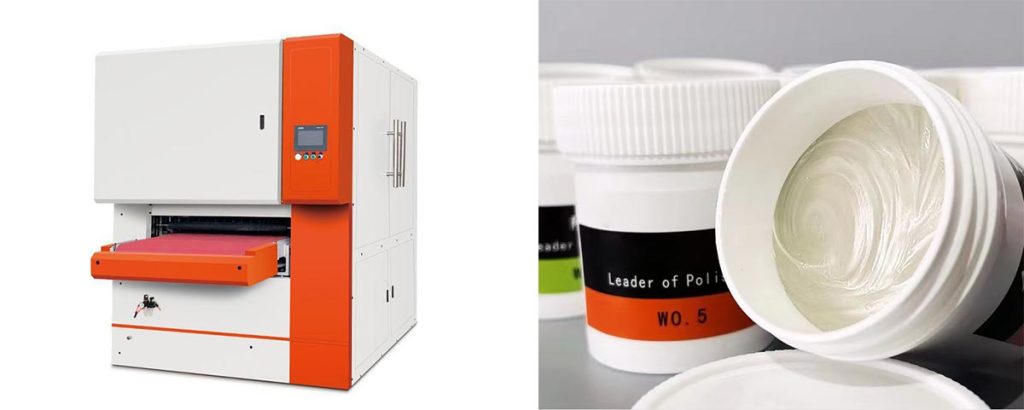

Buffing compounds are specialized abrasive materials designed to smooth and polish surfaces. These compounds typically come in the form of bars or cakes, combining polishing powders, lipids, and waxes. Industries rely on them to enhance the efficiency of buffing wheels and achieve a flawless finish. By removing imperfections like scratches and oxidation, buffing compounds help create a polished surface that meets aesthetic and functional standards.

The versatility of buffing compounds makes them suitable for various materials, including metals, plastics, and wood. Each type of compound serves a specific purpose, from heavy-duty cutting to delicate polishing. Their role in surface finishing has become indispensable in manufacturing, automotive, and jewelry industries.

How Does Buffing Compounds Work?

Buffing compounds work by combining abrasives with a buffing machine to refine surfaces. When applied to a rotating buffing wheel, the compound’s abrasive particles interact with the material’s surface. This process removes imperfections, such as scratches or tarnish, while smoothing the surface. The friction generated by the wheel enhances the compound’s effectiveness, ensuring a consistent finish.

The level of abrasiveness varies depending on the compound type. Cutting compounds, for instance, remove deeper imperfections, while polishing compounds focus on achieving a high-shine finish. The combination of the right compound and buffing tool determines the quality of the final result.

Components of Buffing Compounds

Buffing compounds consist of three primary components:

- Abrasive Materials: These particles determine the compound’s cutting or polishing ability. Coarser abrasives are used for heavy-duty tasks, while finer ones are ideal for delicate finishes.

- Lipids: These act as binders, holding the abrasive particles together and ensuring even application during buffing.

- Waxes: Waxes provide the compound with its solid form, making it easier to apply to buffing wheels.

The combination of these components creates a product that enhances the performance of buffing tools. By selecting the appropriate compound, users can achieve specific finishes, from matte to mirror-like surfaces.

Types of Buffing Compounds and Their Applications

Buffing compounds serve distinct purposes, depending on the material and desired finish. Understanding the types of compounds and their applications ensures effective results in surface finishing. Below is a breakdown of the primary categories of buffing compounds and their specific uses.

Cutting Compounds

Cutting compounds are designed for aggressive material removal. These compounds eliminate deep scratches, oxidation, and other imperfections, preparing surfaces for finer polishing.

Black Emery: For Heavy-Duty Cutting and Scratch Removal

Black Emery is the most abrasive buffing compound. It is ideal for heavy-duty tasks, such as removing deep scratches, small pits, and layers of paint or lacquer. This compound works best on hard metals like steel and iron, making it a go-to choice for industrial applications. Its coarse texture ensures efficient material removal, leaving the surface ready for subsequent polishing stages.

Tip: Use Black Emery with a stiff buffing wheel to maximize its cutting power.

Brown Tripoli: For Smoothing and Polishing Soft Metals

Brown Tripoli is a versatile cutting compound that excels in smoothing and polishing soft metals like brass, copper, and aluminum. It removes minor scratches and imperfections while creating a smooth base for further polishing. This compound is less abrasive than Black Emery, making it suitable for delicate tasks that require precision.

Did You Know? Brown Tripoli is often used in jewelry-making to refine soft metal surfaces before applying a high-shine finish.

Polishing Compounds

Polishing compounds focus on enhancing the surface’s shine and achieving a mirror-like finish. These compounds are less abrasive and are used after cutting compounds to refine the surface further.

Rouge: For High-Shine Finishes on Delicate Metals

Rouge, often red or pink, is a polishing compound specifically formulated for delicate metals like gold, silver, and platinum. It provides a high-shine finish without scratching the surface. Jewelers frequently use Rouge to achieve a mirror-like luster on precious metals.

Fun Fact: Rouge is sometimes referred to as “jeweler’s rouge” due to its widespread use in the jewelry industry.

White Buffing Compound: For Final Finishing Tasks

White Buffing Compound is a versatile option for final finishing. It is suitable for metals, plastics, and wood, delivering a smooth and glossy surface. This compound is less abrasive than Rouge, making it ideal for achieving a flawless mirror finish. It is commonly used in automotive detailing and woodworking projects.

Pro Tip: Pair White Buffing Compound with a soft buffing wheel for the best results.

Specialty Compounds

Specialty compounds are tailored for specific materials or unique polishing requirements. These compounds address challenges that standard cutting compounds or polishing compounds may not handle effectively.

Green Compound: For Stainless Steel and Hard Metals

Green Compound is designed for polishing stainless steel and other hard metals. It removes minor scratches and oxidation while enhancing the material’s natural shine. This compound is highly effective in achieving a mirror-like finish on tough surfaces.

Application Tip: Use Green Compound with a medium-density buffing wheel for optimal performance on stainless steel.

Greystar: For Removing Fire Scale and Enhancing Color

Greystar is a specialty compound used to remove fire scale from metals, particularly after soldering or welding. It also enhances the color and appearance of the surface, making it a popular choice for artisans and metalworkers. Greystar works well on both ferrous and non-ferrous metals.

Quick Insight: Greystar is less abrasive than Black Emery but more aggressive than Rouge, striking a balance between cutting and polishing.

Choosing the Right Buffing Compounds

Selecting the appropriate buffing compound ensures a smooth and efficient buffing process. The right choice depends on several factors, including the material being polished, the desired finish, and the compatibility with buffing wheels. A well-informed decision can save time, reduce effort, and deliver professional results.

Factors to Consider

Material Type (e.g., Metal, Plastic, Wood)

The type of material plays a critical role in determining the ideal buffing compound. Metals like steel or aluminum require compounds with varying abrasiveness levels. For instance, Black Emery works well for hard metals, while Brown Tripoli suits softer metals. Plastics and wood demand gentler compounds to avoid surface damage. Understanding the material’s properties ensures the compound enhances rather than harms the surface.

Quick Tip: Always test the compound on a small area to confirm its suitability for the material.

Desired Finish (e.g., Matte, Glossy, Mirror-Like)

The finish you aim to achieve also influences the choice of buffing compound. Cutting compounds like Black Emery focus on material removal, creating a matte base. Polishing compounds such as Rouge or White Buffing Compound refine the surface, delivering a glossy or mirror-like finish. Specialty compounds like Green Compound enhance the shine of hard metals, while Greystar improves color and removes fire scale.

Pro Tip: Combine cutting and polishing compounds for a complete cut and color process, starting with aggressive material removal and ending with a high-shine polish.

Matching Buffing Compounds to Buffing Wheels

Buffing wheels and compounds work together to achieve the desired results. The wheel’s material and density should complement the compound’s abrasiveness. For example:

- Stiff Buffing Wheels: Pair with cutting compounds like Black Emery for heavy-duty tasks.

- Soft Buffing Wheels: Use with polishing compounds like Rouge or White Buffing Compound for delicate finishes.

- Medium-Density Wheels: Ideal for specialty compounds like Green Compound, balancing cutting and polishing needs.

Matching the right wheel to the compound ensures consistent performance and prevents uneven finishes. Regularly clean and maintain buffing wheels to avoid contamination between compounds.

Did You Know? Using separate buffing wheels for each compound prevents cross-contamination and maintains the integrity of the finish.

Common Applications and Recommendations

Buffing compounds cater to diverse applications across industries. Here are some common uses and recommendations:

- Jewelry Making: Rouge is perfect for polishing gold and silver, creating a high-shine finish without scratches.

- Automotive Detailing: White Buffing Compound refines surfaces, delivering a flawless mirror-like finish on metal and plastic parts.

- Metalworking: Black Emery removes deep scratches and oxidation from steel, while Greystar enhances the color of soldered or welded pieces.

- Woodworking: White Buffing Compound smooths and polishes wooden surfaces, adding a subtle gloss.

Expert Advice: Experiment with different compounds and buffing wheels to find the best combination for your specific project.

Application Tips for Buffing Compounds

Proper application of buffing compounds ensures a smooth and polished finish. This section provides essential tips on tools, techniques, and common mistakes to avoid during the buffing process.

Tools and Equipment

The right tools and equipment play a crucial role in achieving professional results. Selecting appropriate tools ensures efficiency and precision during buffing.

Buffing Wheels and Pads

Buffing wheels are essential for applying buffing compounds effectively. These wheels come in various materials, such as cotton, felt, and sisal, each suited for specific tasks. Stiff buffing wheels work well with cutting compounds, while soft wheels are ideal for polishing compounds. Pads, often made of foam or microfiber, provide additional versatility for smaller or intricate surfaces.

Tip: Use separate buffing wheels for each type of compound to prevent cross-contamination and maintain the integrity of the finish.

Rotary Tools and Drills

Rotary tools and drills offer flexibility for buffing small or detailed areas. These tools allow users to attach buffing wheels or pads for precise application. They are particularly useful for polishing jewelry, automotive parts, or other intricate items. Adjusting the speed of the rotary tool ensures better control and prevents overheating the surface.

Pro Tip: Always secure the buffing wheel or pad firmly to the rotary tool to avoid uneven application or damage.

Step-by-Step Application Process

Following a structured process ensures consistent and high-quality results when using a buffing compound. Below is a step-by-step guide:

- Prepare the Surface: Clean the surface thoroughly to remove dirt, grease, or debris. A clean surface ensures the buffing compound adheres properly.

- Select the Right Buffing Wheel: Choose a wheel that matches the compound and material. For example, use a stiff wheel for cutting compounds and a soft wheel for polishing compounds.

- Apply the Buffing Compound: Rub the compound directly onto the spinning buffing wheel. For liquid buffing compound, apply a small amount evenly across the wheel.

- Buff the Surface: Press the surface gently against the rotating wheel. Move the object or tool in a consistent motion to avoid uneven polishing.

- Inspect the Finish: Check the surface periodically to ensure the desired finish is achieved. Reapply the compound if necessary for additional polishing.

- Clean the Surface: Wipe the surface with a clean cloth to remove any residue left by the compound.

Quick Insight: Avoid applying excessive pressure during buffing, as it may damage the surface or reduce the effectiveness of the compound.

Avoiding Common Mistakes

Mistakes during buffing can lead to unsatisfactory results or damage to the material. Awareness of these errors helps users achieve better outcomes.

- Using the Wrong Buffing Wheel: Mismatched wheels and compounds can result in uneven finishes. Always pair the wheel with the appropriate compound.

- Overloading the Buffing Wheel: Applying too much compound can clog the wheel and reduce its effectiveness. Use a moderate amount for optimal performance.

- Skipping Surface Preparation: Failing to clean the surface before buffing can trap dirt or debris, leading to scratches or imperfections.

- Inconsistent Motion: Holding the surface in one spot for too long can cause overheating or uneven polishing. Maintain a steady and consistent motion.

Expert Advice: Regularly clean buffing wheels to remove buildup and ensure consistent performance.

Conclusion

Understanding the types and uses of buffing compounds empowers users to achieve professional-quality finishes on various materials. Each compound, from cutting to polishing to specialty options, serves a unique purpose in surface refinement. Experimenting with different combinations of compounds and techniques can unlock new possibilities for achieving desired results.

Explore more resources and tools, such as buffing machines, to elevate your projects and master the art of surface polishing.