Metal polish compounds are designed with unique chemical properties that effectively clean, restore, and protect metal surfaces. These compounds work by dissolving oxidation, removing tarnish, and creating a smooth, reflective finish. For example, etchants in the metal polish compound selectively dissolve surface layers, ensuring precise polishing. Proper preparation, such as diluting the metal polish compound with water or solvents, enhances its performance. Fully submerging the metal ensures even application, while carefully monitoring reaction times achieves the desired results. Finally, rinsing and drying the surface prevent corrosion and water spots, preserving the polished finish.

Understanding the chemical properties of a metal polish compound is crucial for achieving the best results. It helps users choose the right compound for specific metals and ensures safe, effective application. This knowledge also reduces the risk of damage and extends the lifespan of metal surfaces.

Key Takeaways

- Metal polish compounds clean metals by removing rust and stains. This makes the metal shiny again.

- Picking the right polish for each metal is important. Aluminum oxide is good for general use. Diamond polish is better for detailed work.

- Use a soft cloth and test on a small spot first. This avoids damage and gives smooth results.

- Some polishes have special ingredients to protect metals from rust. This helps the shine last longer.

- Polishing often makes metals look better and stay clean. It also stops rust, which is useful for decoration and industry.

Understanding Metal Polish Compounds

Purpose and Benefits

Cleaning and Restoring Metal Surfaces

Metal polish compounds play a vital role in cleaning and restoring metal surfaces. These compounds remove dirt, grime, and oxidation layers, revealing the original luster of the material. Polishing compounds like tripolis are particularly effective for soft metals such as brass and copper. They eliminate scratches and dullness, leaving a smooth and reflective finish. In industries like food processing and medical device manufacturing, polished surfaces ensure improved cleanliness, which is essential for maintaining hygiene standards.

Protecting Against Oxidation and Tarnish

Metal polish compounds also protect surfaces from oxidation and tarnish. By creating a barrier, they prevent exposure to air and moisture, which are primary causes of rust and corrosion. For example, finishing rouges deliver a high-quality luster while safeguarding delicate metals like gold and silver. This protective layer enhances the durability of metals, making them suitable for long-term use in decorative and industrial applications.

Key Ingredients

Abrasives (e.g., aluminum oxide, diamond powder)

Abrasives are the backbone of most metal polish compounds. Aluminum oxide, known for its hardness, dominated the market in 2022 due to its effectiveness in achieving glossy finishes. It works well on both soft and hard metals, making it a versatile choice. Diamond compounds, containing micron-sized diamond particles, are used for precision polishing of exceptionally hard materials like gemstones. These abrasives smooth surfaces by removing imperfections, ensuring a professional finish.

Chemical Agents (e.g., acids, alkalis, solvents)

Chemical agents in metal polish compounds dissolve oxidation and stains. Acids are often used for heavy oxidation removal, while alkalis provide gentle cleaning for sensitive surfaces. Solvents help break down grease and other contaminants, ensuring a clean base for polishing. These agents interact with metal oxides to restore the surface’s original appearance without causing damage.

Protective Additives (e.g., waxes, oils)

Protective additives like waxes and oils enhance the quality of metal polish compounds. They form a thin layer on the surface, reducing the risk of future tarnish and oxidation. These additives also improve the compound’s adhesion, ensuring even application. In addition, they contribute to the aesthetic appeal by providing a smooth, shiny finish that lasts longer.

Tip: When selecting a metal polish compound, consider the type of metal and the desired outcome. For example, use aluminum oxide for general polishing or diamond compounds for precision tasks.

Chemical Properties of Metal Polishing Compounds

Acidity and Alkalinity

Breaking Down Oxidation and Stains

Acidity and alkalinity play a crucial role in the effectiveness of metal polish compounds. Acidic solutions excel at breaking down stubborn oxidation and stains on hard metals like stainless steel. These solutions initiate chemical reactions that dissolve surface contaminants, restoring the metal’s original shine. Empirical studies highlight the interaction between active hydroxyl groups in the polishing medium and metal oxides. This interaction facilitates ion exchange and dissolution, which are essential for effective polishing. On the other hand, alkaline-based compounds are better suited for gentle cleaning tasks, especially on softer metals like aluminum and zinc.

Compatibility with Different Metals

The compatibility of metal polish compounds with various metals depends on their pH levels. Neutral pH solutions, such as Maintain Neutral Floor Cleaner, are ideal for cleaning sensitive metals without causing damage. Alkaline cleaners, however, can harm soft metals, making neutral solutions a safer choice. For delicate materials, a close-to-neutral pH ensures effective cleaning while preserving the integrity of the surface.

Abrasiveness

Removing Tarnish and Scratches

Abrasiveness determines how well metal polish compounds remove tarnish and scratches. Compounds containing abrasives like aluminum oxide or diamond powder excel at smoothing surfaces and eliminating imperfections. Quantitative assessments, such as Knoop indentations and subjective evaluations, measure the effectiveness of these compounds. Numerical ratings for scratch and tarnish removal provide insights into their performance, ensuring users select the right compound for their needs.

Balancing Surface Safety and Effectiveness

Balancing abrasiveness with surface safety is essential for achieving optimal results. Comparative data shows that aqueous carriers and gamma alumina offer moderate tarnish removal with minimal surface damage. For example, gamma alumina achieves very low scratch levels while maintaining effective tarnish removal. This balance ensures that metal surfaces retain their structural integrity during polishing.

| Abrasive Type | Tarnish Removed | Surface Damage (Scratches) | Silver Loss |

|---|---|---|---|

| Alcohol Carrier | High | High | High |

| Aqueous Carrier | Moderate | Low | Low |

| Calcium Carbonate | Moderate | Low (some scratches) | Low |

| Gamma Alumina | Moderate | Very Low | Low |

| Chromium Oxide | Moderate | Low | Low |

Surface Tension and Adhesion

Spreading and Adhering to Metal Surfaces

Surface tension and adhesion influence how metal polish compounds spread and adhere to surfaces. Compounds with lower surface tension distribute evenly, ensuring consistent polishing results. Protective additives like waxes and oils enhance adhesion, forming a thin layer that shields the metal from future tarnish and oxidation. This property is particularly beneficial for maintaining polished finishes over time.

Interaction with Metal Oxides and Contaminants

Metal polish compounds interact with metal oxides and contaminants to restore surfaces. Chemical agents in these compounds dissolve oxidation layers and break down grease, creating a clean base for polishing. This interaction modifies the surface at a molecular level, enhancing the compound’s effectiveness. Studies on glass polishing reveal similar processes, where ion exchange and dissolution improve surface quality.

Types of Metal Polishing Compounds

Abrasive-Based Compounds

Aluminum Oxide for General Use

Aluminum oxide stands out as a versatile abrasive in metal polish compounds. Its hardness and durability make it suitable for both soft and hard metals. This compound effectively removes scuffs and prepares surfaces for final polishing stages. Industries such as aerospace and automotive favor aluminum oxide for its ability to achieve a glossy finish. In 2022, it dominated the market due to its superior abrasive properties, which are essential for producing high-quality polished surfaces.

Tip: Aluminum oxide compounds are ideal for restoring the luster of metals while enhancing their aesthetic appeal.

Diamond Compounds for Precision Polishing

Diamond compounds contain micron-sized diamond particles, making them perfect for precision polishing tasks. These compounds excel in applications requiring meticulous attention to detail, such as polishing gemstones or high-value metal components. Their exceptional hardness ensures the removal of fine scratches without damaging the surface. Diamond-based compounds are indispensable in industries like jewelry and electronics, where achieving a flawless finish is critical.

Chemical-Based Compounds

Acidic Polishes for Heavy Oxidation

Acidic polishes are designed to tackle heavy oxidation and stubborn stains on hard metals. These compounds initiate chemical reactions that dissolve surface contaminants, restoring the metal’s original shine. Jeweler’s rouge, a common example, is widely used for polishing gold and silver. Acidic polishes are particularly effective in industrial settings where metals are exposed to harsh environments.

Alkaline Polishes for Gentle Cleaning

Alkaline polishes provide a gentler alternative for cleaning sensitive metals like aluminum and zinc. These compounds remove light tarnish and stains without causing damage. They are often used in applications where preserving the integrity of the metal surface is crucial. For instance, alkaline-based solutions are popular in the jewelry industry for maintaining the brilliance of delicate pieces.

Multi-Purpose Compounds

Combining Abrasives and Protective Agents

Multi-purpose compounds combine abrasives with protective additives like waxes and oils. This combination allows them to clean, polish, and protect metal surfaces in a single application. These compounds are highly versatile, making them suitable for a wide range of metals and applications. They not only remove tarnish and scratches but also leave a protective layer that prevents future oxidation.

Examples of Popular Multi-Purpose Products

Popular multi-purpose products include finishing rouges and rubbing compounds. These high-quality metal polish compounds are widely used in both industrial and decorative applications. For example, tripolis are effective for preliminary polishing, while finishing rouges deliver a smooth, reflective finish. These products cater to diverse needs, from restoring antique metal pieces to maintaining modern machinery.

Note: Multi-purpose compounds are an excellent choice for users seeking convenience and efficiency in metal polishing tasks.

Applications of Metal Polish Compounds on Different Surfaces

Polishing Soft Metals

Aluminum and Brass: Avoiding Over-Abrasiveness

Soft metals like aluminum and brass require careful handling during polishing to avoid over-abrasiveness. Surface preparation plays a critical role in achieving effective results. Cleaning the surface thoroughly removes dirt and grease, ensuring the polish adheres evenly. Precision in application is equally important. Uneven coverage can lead to inconsistent finishes or damage. Tripolis compounds, particularly Brown Tripoli, are highly effective for cutting and finishing these metals. Brown Tripoli excels at removing scratches from brass, copper, and aluminum, leaving a smooth and reflective surface.

Tip: Always test the compound on a small area before full application to ensure compatibility with the metal.

Choosing the Right Compound for Soft Metals

Selecting the appropriate metal polish compounds for soft metals ensures optimal results. Abrasive-based compounds with fine particles work best for aluminum and brass. These compounds remove tarnish and scratches without causing excessive wear. Multi-purpose compounds that combine abrasives with protective agents are also suitable. They clean, polish, and protect in one step, making them a convenient choice for soft metals.

Polishing Hard Metals

Stainless Steel and Chrome: Restoring Shine

Hard metals like stainless steel and chrome benefit from polishing compounds designed for durability. These compounds remove oxidation and restore the metal’s natural shine. Aluminum oxide-based compounds are particularly effective for these metals. They smooth out imperfections and enhance the reflective quality of the surface. In industries like automotive manufacturing, polished stainless steel and chrome components improve both aesthetics and functionality.

Protective Coatings for Long-Term Results

Metal polish compounds not only restore shine but also provide long-term protection. They create a barrier that prevents oxidation and rusting. This protective layer enhances the durability of hard metals, making them resistant to scratches and wear. In the automotive industry, these compounds reduce friction and prevent corrosion, improving the performance and efficiency of metal components.

Note: Regular maintenance with protective compounds extends the lifespan of polished hard metals.

Special Considerations for Precious Metals

Gold and Silver: Gentle Cleaning Techniques

Precious metals like gold and silver require gentle cleaning techniques to preserve their value and appearance. Compounds containing calcium carbonate or gamma alumina are ideal for these metals. Calcium carbonate effectively removes tarnish but may cause shallow scratches on silver surfaces. Gamma alumina, on the other hand, leaves a highly reflective finish with fewer scratches.

| Abrasive Material | Effectiveness | Damage Level | Notes |

|---|---|---|---|

| Calcium Carbonate | High | Some scratches | Performed well but may cause shallow scratches on silver surfaces. |

| Gamma Alumina | Very High | Fewer scratches | Leaves a highly reflective surface, which may be objectionable. |

| Chromium Oxide | Moderate | More labor | Less favored due to the labor involved in cleaning residue. |

Avoiding Damage to Plated Surfaces

Plated surfaces, such as gold-plated jewelry, require extra care during polishing. Overly abrasive compounds can strip the plating, exposing the base metal underneath. Non-abrasive or mildly abrasive compounds are the safest choice for these surfaces. Applying the polish with a soft cloth and using light pressure minimizes the risk of damage.

Conclusion

Understanding the chemical properties of metal polish compounds is essential for achieving optimal results. These compounds restore the luster of metals, address oxidation issues, and enhance their appearance. Industries like automotive and aerospace rely on these benefits to maintain functionality and aesthetics.

- Polishing improves corrosion resistance, protecting metals from rust and wear.

- A polished surface ensures better hygiene by preventing bacteria build-up.

- Enhanced durability and visual appeal make polished metals ideal for consumer-focused industries.

- In 2022, aluminum oxide led the global market due to its hardness and ability to create a glossy finish.

- Its consistent use highlights its reliability in enhancing metal products.

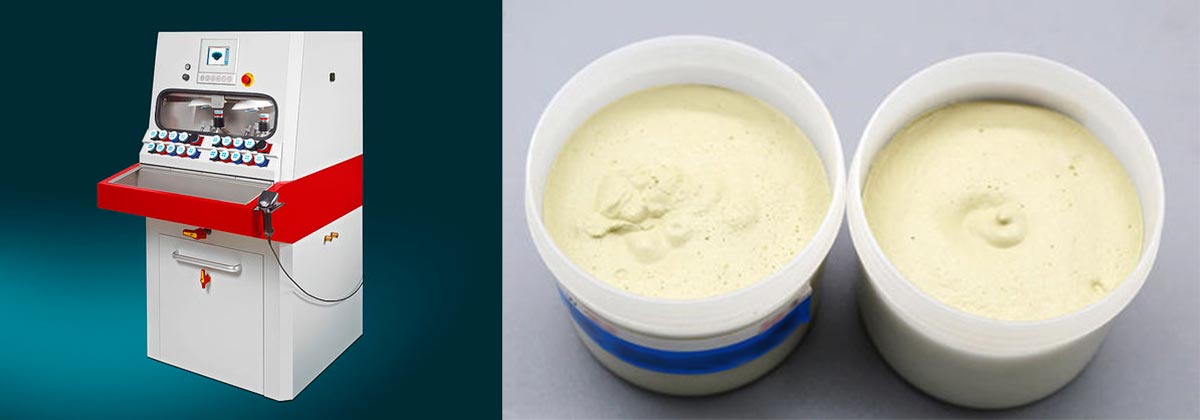

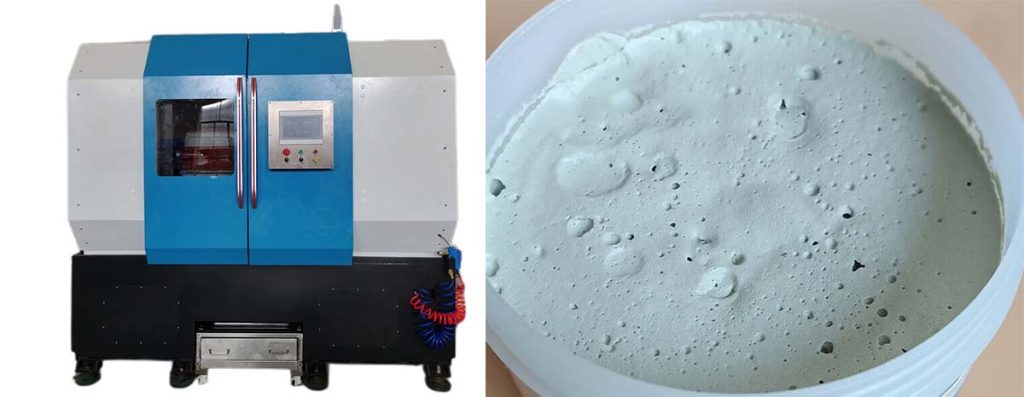

Selecting the right compound ensures long-lasting results, whether for soft metals, hard metals, or precious surfaces. Knowledge of these properties, combined with tools like a metal polishing machine, extends the lifespan of metals while maintaining their brilliance.