Maintaining an industrial buffing machine is crucial for ensuring its longevity and optimal performance. Regular upkeep not only enhances the machine’s efficiency but also prevents unexpected breakdowns, reducing repair costs and extending its lifespan. Preventive maintenance plays a vital role in this process. According to a survey by Plant Engineering, 88% of manufacturing companies rely on preventive maintenance to keep their operations running smoothly. This proactive approach involves routine care, such as lubrication and part replacements, which maximizes equipment longevity and minimizes downtime.

Key Takeaways

- Implement daily cleaning routines to remove dust and debris, ensuring optimal machine performance and longevity.

- Conduct regular inspections for wear and tear, focusing on belts, pads, and loose parts to prevent unexpected breakdowns.

- Apply the correct lubricants weekly to reduce friction and maintain smooth operation, preventing wear and tear on moving parts.

- Perform thorough electrical system checks to identify and address potential issues, ensuring safe and efficient machine operation.

- Engage in monthly deep cleaning and performance testing to maintain internal components and evaluate machine efficiency.

- Address common problems like inconsistent buffing results by adjusting machine settings and replacing worn buffing pads promptly.

- Prioritize preventive maintenance to minimize repair costs and downtime, ultimately enhancing productivity and product quality.

Daily Maintenance Tips for Industrial Buffing Machines

Regular maintenance is essential for the optimal performance of an industrial buffing machine. Daily care routines ensure that the machine operates efficiently and reduces the risk of unexpected breakdowns. Here are some preventative maintenance tips to keep your equipment in top condition.

Cleaning the Machine

A clean machine performs better and lasts longer. Dust and debris can accumulate on the surfaces and internal components, leading to inefficiencies and potential damage.

Removing Dust and Debris

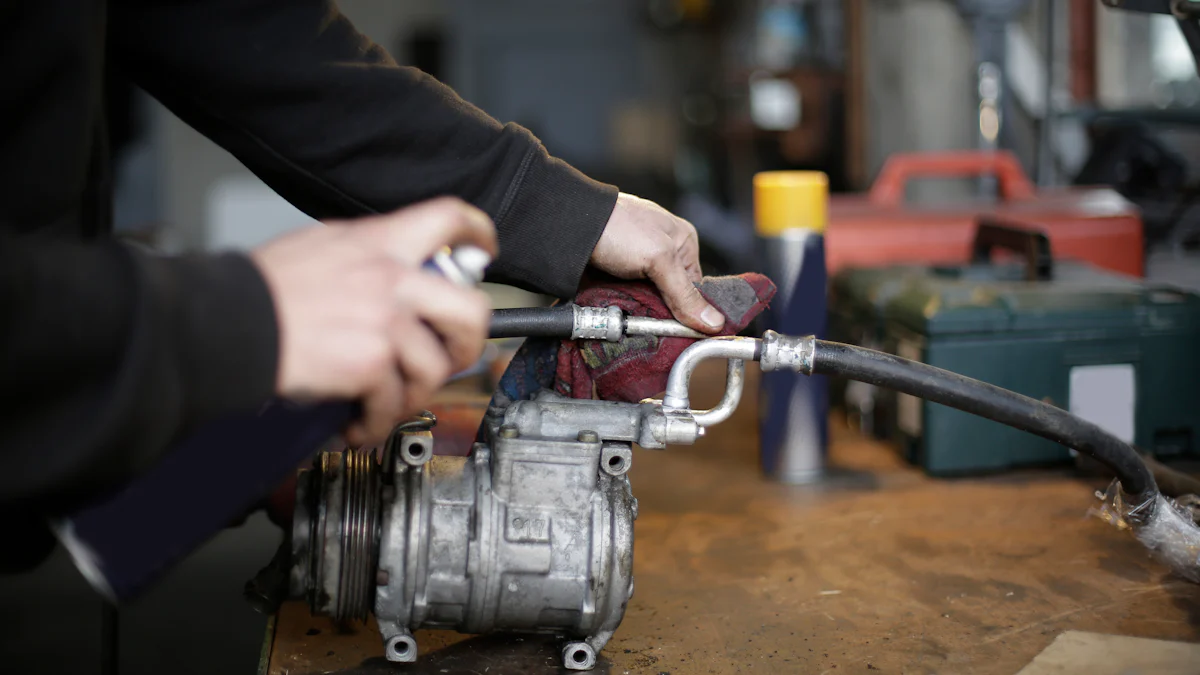

Operators should begin by removing dust and debris from the machine. Use a dry cloth or brush to gently clean the motor housing and other external parts. For more stubborn dirt, a damp cloth with mild detergent can be effective. Avoid using rough cleaning tools that might scratch the surfaces.

Wiping Down Surfaces

After removing dust, wipe down all surfaces with a damp cloth. This step ensures that any remaining residues are eliminated. Pay special attention to areas around the controls and moving parts. Keeping these areas clean prevents operational issues such as a floor buffer not turning on due to clogged components.

Inspecting for Wear and Tear

Daily inspections help identify potential problems before they escalate. Regular checks can prevent issues like a floor buffer won’t stay on, which often results from neglected maintenance.

Checking Belts and Pads

Inspect the belts and pads for signs of wear. Worn-out belts can slip or break, affecting the machine’s performance. Similarly, buffing pads should be checked for debris and replaced if necessary to maintain consistent buffing quality.

Identifying Loose Parts

Loose parts can lead to significant mechanical failures. Examine the machine for any loose screws, bolts, or other components. Tighten them as needed to ensure the machine operates smoothly. This simple step is crucial for effective industrial floor maintenance.

By incorporating these daily maintenance practices, operators can significantly extend the lifespan of their industrial buffing machines. Following the manufacturer’s guidelines and maintaining a routine inspection schedule will help avoid costly repairs and downtime.

Weekly Maintenance Tips for Proper Machine Maintenance

Weekly maintenance routines are essential for ensuring the reliability and efficiency of an industrial buffing machine. These tasks help prevent unexpected failures and extend the lifespan of the equipment. Maintenance Expert emphasizes, “Regular maintenance is the backbone of machine reliability.” By adhering to a weekly schedule, operators can address potential issues before they escalate.

Lubrication

Lubrication plays a critical role in maintaining the smooth operation of an industrial buffing machine. Proper lubrication reduces friction between moving parts, preventing wear and tear.

Applying Appropriate Lubricants

Operators should apply the correct type of lubricant as specified by the manufacturer. Using inappropriate lubricants can lead to improper lubrication, which may cause the machine to malfunction. A well-lubricated machine operates more efficiently and experiences fewer breakdowns.

Ensuring Moving Parts Are Well-Oiled

Regularly monitor lubrication levels to ensure all moving parts are adequately oiled. This practice prevents issues such as a floor buffer is vibrating due to insufficient lubrication. Consistent lubrication helps maintain the machine’s performance and prolongs its lifespan.

Electrical System Check

A thorough inspection of the electrical system is vital for safe and efficient machine operation. Regular checks help identify potential electrical issues that could lead to costly repairs or downtime.

Inspecting Wiring and Connections

Operators should inspect all wiring and connections for signs of wear or damage. Loose or frayed wires can cause electrical malfunctions, affecting the machine’s performance. Addressing these issues promptly ensures the machine operates safely and efficiently.

Testing Safety Switches

Safety switches play a crucial role in preventing accidents during industrial floor maintenance. Regular testing of these switches ensures they function correctly, providing an additional layer of safety for operators. A malfunctioning safety switch can lead to severe consequences, including equipment damage or personal injury.

By incorporating these weekly maintenance practices, operators can significantly enhance the performance and longevity of their industrial buffing machines. Routine lubrication and electrical system checks are essential components of a comprehensive machine maintenance plan. These steps help prevent issues like a floor buffer is dulling, ensuring consistent and high-quality results.

Monthly Maintenance Tips for Industrial Buffing Machines

Monthly maintenance routines are crucial for ensuring the long-term efficiency and reliability of an industrial buffing machine. These tasks involve more in-depth procedures that address potential issues before they affect performance.

Deep Cleaning

Deep cleaning is essential for maintaining the internal components of the machine. This process helps prevent the accumulation of dirt and debris, which can lead to mechanical failures.

Disassembling Parts for Thorough Cleaning

Operators should begin by carefully disassembling the machine. This step allows access to areas that are not reachable during daily or weekly maintenance. Each part should be cleaned individually to remove any buildup that could hinder performance. Proper reassembly is vital to avoid issues such as improper lubrication, which can cause a floor buffer to vibrate.

Cleaning Internal Components

Once disassembled, operators should focus on cleaning the internal components. Use appropriate cleaning tools and solutions to ensure all parts are free from contaminants. This thorough cleaning helps maintain the machine’s efficiency and prevents problems like a floor buffer dulling over time.

Performance Testing

Performance testing is a critical aspect of monthly maintenance. It ensures that the machine operates at optimal levels and identifies any areas that may require attention.

Running Diagnostic Tests

Operators should run diagnostic tests to evaluate the machine’s performance. These tests help identify any underlying issues that might not be apparent during regular operation. Addressing these issues promptly can prevent costly repairs and downtime.

Evaluating Machine Efficiency

After completing diagnostic tests, operators should evaluate the machine’s efficiency. This evaluation involves assessing the machine’s output and comparing it to expected performance levels. Any discrepancies should be investigated and resolved to ensure the machine continues to operate effectively.

By incorporating these monthly maintenance practices, operators can significantly enhance the longevity and performance of their industrial buffing machines. Regular deep cleaning and performance testing are essential components of a comprehensive machine maintenance plan. These steps help prevent issues like a floor buffer dulling, ensuring consistent and high-quality results.

Common Problems and Solutions for Industrial Buffing Machines

Industrial buffing machines, like any other industrial equipment, can encounter various issues that affect their performance. Understanding these common problems and implementing effective solutions can significantly enhance the machine’s longevity and efficiency.

Electrical Malfunctions

Electrical malfunctions often disrupt the operation of an industrial buffing machine. These issues can range from minor wiring problems to significant motor issues.

Identifying Faulty Wiring

Operators should regularly inspect the wiring for signs of wear or damage. Frayed or loose wires can lead to a floor buffer not turning on. A thorough examination of the electrical components helps in identifying potential hazards. Using a multimeter can assist in detecting faulty connections, ensuring the machine operates safely.

Repairing or Replacing Damaged Components

Once faulty wiring is identified, immediate action is necessary. Repairing or replacing damaged components prevents further damage and ensures the machine functions efficiently. Engaging experienced maintenance professionals for these repairs guarantees that the work meets industry standards, reducing the risk of recurring issues.

Inconsistent Buffing Results

Inconsistent buffing results can compromise the quality of the finished product. Addressing these issues promptly maintains the machine’s performance and ensures high-quality outcomes.

Adjusting Machine Settings

Operators should regularly review and adjust machine settings to ensure optimal performance. Incorrect settings can lead to a floor buffer is dulling, affecting the quality of the buffing process. Proper calibration of speed and pressure settings enhances the machine’s efficiency and ensures consistent results.

Inspecting Buffing Pads for Wear

Buffing pads play a crucial role in achieving desired results. Regular inspection of pads is essential to identify wear and tear. A worn pad can lead to uneven buffing, while a floor pad is installed incorrectly or a floor pad is damaged can cause a floor buffer won’t stay on. Replacing worn pads with new ones ensures consistent quality and prevents further machine issues.

By addressing these common problems, operators can maintain the condition of their industrial buffing machines effectively. Implementing regular maintenance procedures and engaging professional repair services when necessary will enhance the machine’s longevity and performance. This proactive approach minimizes downtime and ensures the commercial floor buffer operates at its best.

Conclusion

Regular maintenance of an industrial buffing machine is essential for maximizing its efficiency and longevity. By adhering to a consistent maintenance schedule, operators can prevent minor issues from escalating into major problems, thereby reducing repair costs and downtime. Implementing the tips provided in this guide ensures that the machine operates smoothly and consistently delivers high-quality results. For complex repairs or when in doubt, seeking professional assistance is advisable to maintain the machine’s optimal performance. Prioritizing maintenance not only extends the machine’s lifespan but also enhances productivity and product quality.

FAQ

How often should industrial buffing machines be maintained?

Regular maintenance is crucial for optimal performance. Operators should perform daily cleaning and inspections, weekly lubrication and electrical checks, and monthly deep cleaning and performance testing. This routine ensures the machine operates efficiently and prolongs its lifespan.

What are the key benefits of preventive maintenance for buffing machine?

Preventive maintenance minimizes unexpected breakdowns, reduces repair costs, and extends the machine’s lifespan. It involves routine care such as lubrication and part replacements, which enhance equipment longevity and minimize downtime.

Can buffing be done manually without a machine?

Buffing can be done by hand, but it requires more time and effort. The results may not be as consistent as when using specialized equipment. Industrial buffing machines provide more efficient and uniform results, making them preferable for large-scale operations.

How do you select the right buffing machine for your needs?

Selecting the right buffing machine depends on the specific requirements of the task. Consider factors such as the type of surface, the desired finish, and the frequency of use. Consulting with a professional or referring to manufacturer guidelines can help in making an informed decision.

What should operators do if they encounter electrical malfunctions?

Operators should inspect wiring and connections for signs of wear or damage. Immediate action, such as repairing or replacing faulty components, is necessary to prevent further issues. Engaging experienced maintenance professionals ensures repairs meet industry standards.

How can inconsistent buffing results be addressed?

Inconsistent results often stem from incorrect machine settings or worn buffing pads. Operators should regularly review and adjust settings for optimal performance. Inspecting and replacing worn pads ensures consistent quality and prevents further machine issues.

What role does lubrication play in machine maintenance?

Lubrication reduces friction between moving parts, preventing wear and tear. Applying the correct type of lubricant as specified by the manufacturer ensures smooth operation and reduces the risk of breakdowns.

Why is deep cleaning important for industrial buffing machines?

Deep cleaning prevents the accumulation of dirt and debris in internal components, which can lead to mechanical failures. Disassembling parts for thorough cleaning maintains the machine’s efficiency and prevents issues like a floor buffer dulling over time.

How can operators ensure the safety of industrial buffing machines?

Regular inspection of safety switches and electrical systems is vital. Testing these components ensures they function correctly, providing an additional layer of safety for operators. Proper training on machine operation and maintenance procedures also reduces the risk of accidents.

When should professional assistance be sought for machine repairs?

For complex repairs or when in doubt, seeking professional assistance is advisable. Certified technicians ensure that repairs meet industry standards, maintaining the machine’s optimal performance and reducing the risk of recurring issues.