Brass polishing compound is essential for restoring the beauty of brass surfaces. The product removes tarnish and oxidation while smoothing imperfections. They achieve this through a combination of chemical reactions and mechanical abrasion. The chemical agents dissolve tarnish, while abrasive particles refine the surface. This dual action brings back the original shine and smoothness of the metal. Using a brass polishing compound correctly ensures effective results and prolongs the life of brass items.

Key Takeaways

- Brass polish makes brass shiny by cleaning off tarnish and flaws.

- The right mix of chemicals and abrasives cleans brass safely.

- Using proper tools and steady pressure gives better polishing results.

- Regular use of polish stops tarnish and keeps brass lasting longer.

- Adding a protective layer after polishing keeps it shiny and clean.

The Chemical Composition of Brass Polishing Compound

Key Ingredients and Their Roles

Abrasive Particles for Surface Refinement

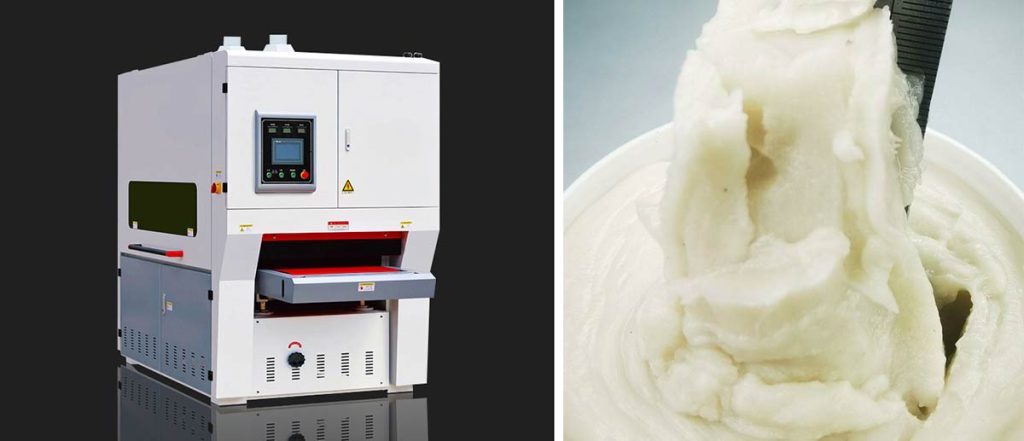

Abrasive particles play a crucial role in the polishing process. These particles are responsible for smoothing the brass surface by removing imperfections such as scratches and stains. The abrasives in a brass polishing compound are carefully selected to balance efficiency and surface quality. Their size and shape determine how effectively they refine the surface without causing damage. This mechanism ensures that the brass achieves a polished and uniform finish.

Chemical Agents for Tarnish and Oxidation Removal

Chemical agents are essential for the removal of tarnish and oxidation from brass surfaces. These agents work through chemical reactions like oxidation and reduction to dissolve the tarnish layer. For example, hydrochloric acid accelerates tarnish removal, while oxalic acid cleans and bleaches the surface. The choice of chemical agents depends on the type of tarnish and the desired surface quality. These agents enhance the efficiency of the polishing process by targeting specific contaminants.

| Chemical Agent | Reaction Outcome |

|---|---|

| Hydrochloric Acid | Rapid tarnishing |

| Citric Acid | Surface corrosion |

| Oxalic Acid | Cleaning and bleaching |

Additives for Protection and Long-Lasting Shine

Additives in brass polishing compound improve the overall quality of the process. These components include lubricants and surfactants, which reduce friction during polishing and enhance the compound’s spreadability. Additionally, protective additives form a thin layer on the brass surface, preventing future tarnish and oxidation. This protective mechanism ensures that the polished brass retains its shine for an extended period.

How the Composition Impacts Polishing Results?

The Balance Between Abrasiveness and Gentleness

The balance between abrasiveness and gentleness in a polishing compound determines its effectiveness. Abrasive properties help remove imperfections, while gentleness ensures the brass surface remains undamaged. A well-formulated compound achieves this balance by tailoring the abrasive size and morphology to the substrate. This approach enhances the efficiency of the polishing process while minimizing material loss.

- Abrasive properties facilitate the removal of imperfections.

- Gentleness ensures a smooth, polished finish.

- Proper balance reduces material usage and improves productivity.

Compatibility with Different Brass Finishes

Brass polishing compound is designed to work with various brass finishes. Cutting compounds like the Brown Compound remove deep scratches, while polishing compound such as the Blue Compound provide a glossy finish. Commercial options like Green Rouge Buffing Compound and White Rouge Buffing Compound cater to specific needs, from gentle cutting to achieving a mirror finish polishing. This compatibility ensures that the compound delivers optimal results for different surface qualities.

The Science Behind Polishing Brass

Chemical Reactions in Tarnish Removal

Oxidation and Reduction Processes Explained

Tarnish forms on brass surfaces due to chemical reactions involving moisture and air. These reactions lead to the oxidation of copper, a key component of brass, resulting in a dull and discolored appearance. During the polishing process, the brass polishing compound initiates reduction reactions to reverse this oxidation. Reduction restores the original luster by breaking down the tarnish layer into removable particles. This mechanism ensures effective tarnish removal while preserving the surface quality of the brass.

Interaction of Acids and Bases with Brass Surfaces

Acids play a significant role in the tarnish removal process. For instance, hydrochloric acid accelerates the etching of tarnish, while citric acid gently cleans the surface. These acids react with the tarnish layer, dissolving it and exposing the polished brass beneath. However, the compound must balance the properties of these acids to avoid over-etching, which could damage the surface. Bases, on the other hand, neutralize any residual acids, ensuring the brass remains stable after polishing.

| Chemical Agent | Reaction Outcome |

|---|---|

| Moisture | Oxidation of copper |

| Air | Formation of oxides |

| Hydrochloric Acid | Rapid tarnishing |

| Citric Acid | Surface corrosion |

| Skin Oils | Accelerated tarnishing |

Mechanical Abrasion and Surface Refinement

Role of Abrasives in Removing Imperfections

Abrasive particles in the polishing compound physically remove imperfections like scratches and stains. These particles act as tiny cutting tools, scraping away the tarnish and smoothing the surface. The size and hardness of the abrasives determine their efficiency in refining the surface. This mechanical action ensures that the brass achieves a polished and uniform finish, enhancing its overall quality.

How Friction Contributes to a Polished Finish

Friction generated during the polishing process creates heat, which softens the tarnish layer and facilitates its removal. This heat also activates the chemical agents in the compound, improving their efficiency. The combination of friction and abrasives ensures a smooth and polished surface, restoring the brass to its original shine.

Combining Chemical and Mechanical Actions

Why Dual-Action Compounds Are More Effective?

Brass polishing compound that combines chemical and mechanical actions deliver superior results. The chemical agents dissolve tarnish, while the abrasives refine the surface. This dual-action mechanism enhances the efficiency of the polishing process, ensuring thorough tarnish removal and a polished finish. By addressing both chemical and physical imperfections, these compounds improve the surface quality of brass items.

Practical Examples of This Synergy in Action

For heavily tarnished brass, the chemical agents break down the thick tarnish layer, allowing the abrasives to remove it more effectively. In contrast, lightly oxidized surfaces benefit from the gentle action of both components, achieving a mirror finish polishing. This synergy between chemical and mechanical polishing ensures optimal results for various brass finishes, making it a versatile solution for restoring brass surfaces.

Factors Influencing the Effectiveness of Polishing Compound

Surface Condition of the Brass

Differences Between Heavily Tarnished and Lightly Oxidized Surfaces

The condition of the brass surface significantly impacts the polishing process. Heavily tarnished surfaces require more intensive treatment due to the thick layer of oxidation. In such cases, the chemical agents in the brass polishing compound play a crucial role in breaking down the tarnish. Lightly oxidized surfaces, on the other hand, benefit from a gentler approach. The mechanical action of abrasives ensures the removal of minor imperfections while preserving the surface quality. Understanding the level of tarnish helps in selecting the appropriate polishing method for optimal results.

Impact of Scratches, Dents, and Other Imperfections

Scratches and dents on brass surfaces affect the efficiency of the polishing compound. Abrasive particles smooth out minor scratches, but deeper imperfections may require additional preparation, such as sanding. The mechanical mechanism of the compound works best on relatively even surfaces, ensuring a polished finish. Addressing these imperfections before polishing enhances the overall surface quality and ensures a uniform shine.

Application Techniques and Tools

Choosing the Right Tools (Cloths, Brushes, Pads)

The tools used during polishing influence the outcome of the process. Selecting the appropriate tool ensures effective application and removal of the compound. The table below highlights some commonly used tools and their purposes:

| Tool/Material | Purpose |

|---|---|

| Drill or Rotary Tool | For mounting polishing mops |

| Mandrel | To hold polishing mops |

| Backing Pads | Support for polishing mops |

| Lint-free Soft Cloths | For final cleaning and polishing |

| Dry Sisal Polishing Mop | Initial polishing to remove scratches |

| White Stitched Polishing Mop | Intermediate polishing to smooth surfaces |

| WDR Polishing Mop | Final polishing for a reflective shine |

| Wet/Dry Sandpaper (600-2000 grit) | Smoothing surfaces before polishing |

Using the right tools ensures the polishing compound achieves its maximum efficiency, improving the surface quality of the brass.

Importance of Pressure, Motion, and Consistency

The operator’s technique during polishing directly affects the results.

- Slow arm movements combined with moderate pressure ensure even application and effective removal of imperfections.

- Excessive speed or pressure can lead to uneven finishes or surface damage.

- Consistent motion prevents over-etching and maintains the surface quality.

Proper technique enhances the efficiency of the polishing process and ensures a polished, uniform finish.

Time and Frequency of Polishing

How Long to Leave the Compound on the Surface?

The duration for which the polishing compound remains on the brass surface impacts its effectiveness. Allowing the compound to sit for a few minutes enables the chemical agents to break down tarnish and oxidation. However, leaving it for too long may lead to over-etching, which can damage the surface. Following the manufacturer’s instructions ensures the process achieves the desired results without compromising the surface quality.

Benefits of Regular Maintenance for Long-Term Results

Regular maintenance preserves the beauty and longevity of brass items.

- Cleaning and polishing restore the natural shine and prevent tarnish buildup.

- Removing contaminants and oxidation reduces the risk of corrosion.

- Applying protective coatings, such as mineral oil or car wax, delays oxidation and maintains luster.

- Establishing a routine simplifies future maintenance and ensures the brass retains its value over time.

Consistent care enhances the efficiency of the polishing process and ensures the brass remains polished and visually appealing.

Practical Tips for Using Brass Polishing Compound

Preparing the Brass Surface

Cleaning and Drying the Surface Before Polishing

Proper preparation ensures the polishing process achieves optimal results. Follow these steps to clean and dry the brass surface:

- Wash the brass with warm, soapy water to remove dirt and grease.

- Use a soft-bristled toothbrush to clean intricate details.

- Rinse thoroughly and dry the brass with a lint-free cloth.

- For stubborn grime, create a paste using equal parts white vinegar and salt. Apply it to the tarnished areas, then rinse and dry.

- Sand the brass with appropriate grit sandpaper if the surface has scratches or uneven areas.

Thorough cleaning removes contaminants that could interfere with the polishing compound’s efficiency.

Identifying Problem Areas for Targeted Treatment

Inspect the brass for tarnish, scratches, or dents. Focus on heavily tarnished sections by applying additional cleaning solutions or sanding. Addressing these areas ensures the polishing compound works effectively, enhancing surface quality.

Applying the Polishing Compound

Using the Right Amount of Product for Even Coverage

Apply a small amount of the polishing compound to a soft cloth or buffing wheel. Spread it evenly across the brass surface. Overuse can lead to residue buildup, reducing polishing efficiency.

Techniques for Effective Application and Polishing

- Wear gloves to avoid fingerprints on the polished surface.

- Use circular motions to apply the compound, ensuring even coverage.

- Maintain steady pressure to avoid over-etching or uneven polishing.

- For a mirror finish, use finer grit sandpaper before applying the compound.

- Buff the surface with a clean cloth or rotary tool for a smooth, polished appearance.

These techniques maximize the compound’s efficiency and improve the surface quality of the brass.

Post-Polishing Care and Maintenance

Removing Residue and Buffing for a Final Shine

After polishing, rinse the brass with warm water to remove residue. Dry it thoroughly with a soft, lint-free cloth. Buff the surface using a microfiber cloth in small circular motions. This step enhances the shine and ensures a mirror finish.

Protecting the Surface to Prevent Future Tarnish

Apply a protective coating, such as wax or lacquer, to create a barrier against tarnishing. Store brass items in a dry, temperature-controlled environment. Use tarnish inhibitors to absorb moisture and sulfur compounds in the air. These measures preserve the polished surface and prolong its quality.

Conclusion

Brass polishing compound restores the luster and smoothness of brass surfaces by combining chemical and mechanical processes. Its proper use ensures effective tarnish removal and surface refinement. Regular maintenance with these compounds offers numerous benefits, as shown below:

| Benefit | Description |

|---|---|

| Enhanced Appearance | Regular cleaning and polishing restore brass’s natural shine, keeping it looking new and well-maintained. |

| Longevity | Prevents long-term damage by removing contaminants and tarnish, significantly extending lifespan. |

| Preventing Corrosion | Removes corrosive elements and adds a protective layer to reduce corrosion risk. |

| Ease of Maintenance | Establishing a routine makes maintenance easier and prevents stubborn tarnish build-up. |

| Value Preservation | Well-maintained items retain their value better, especially antiques that can lose value if neglected. |

Understanding the composition of brass polishing compound and applying it correctly ensures optimal results. Consistent care not only preserves the beauty of brass items but also extends their lifespan, making them a valuable addition to any collection.