Achieving a flawless bike frame finish relies on the effective use of buffing and polishing compounds. These compounds remove surface irregularities, revealing a smooth and uniform texture. A proper polish not only enhances the visual appeal but also strengthens the frame against wear and tear. In 2025, advancements in material science and manufacturing techniques make polishing more efficient and eco-friendly. Manufacturers now achieve higher precision with minimal waste, ensuring every bike frame meets modern aesthetic and durability standards.

Key Takeaways

- Buffing and polishing make bike frames look better and shiny.

- A smooth surface helps bike frames last longer by stopping damage.

- Polished frames cut air resistance, making bikes faster and better.

- Good tools and careful work are needed for perfect polishing.

- Using better polishing methods helps bike makers stand out in sales.

The Role of Buffing and Polishing Compounds in Bike Frame Manufacturing

Enhancing Aesthetic Appeal and Brand Value

Buffing and polishing compounds play a vital role in creating visually appealing bicycle frames. These compounds remove scratches, blemishes, and uneven textures from metal surfaces, leaving behind a smooth and uniform finish. A polished frame reflects light beautifully, giving it a professional shine that attracts customers.

Manufacturers understand the importance of aesthetics in building brand value. A well-polished frame not only enhances the product’s appearance but also communicates quality and craftsmanship. This attention to detail helps brands stand out in a competitive market.

A polished aluminium frame, for example, showcases a sleek and modern design that appeals to riders seeking both style and performance.

By investing in advanced buffing and polishing techniques, manufacturers ensure their products meet the high expectations of today’s consumers.

Improving Durability and Resistance to Wear

Buffing and polishing compounds contribute significantly to the durability of bike frames. The polishing process removes surface imperfections that could lead to corrosion or wear over time. A smooth finish reduces the likelihood of dirt and moisture accumulating in crevices, protecting the frame from environmental damage.

Polished metal surfaces are less prone to scratches and abrasions, ensuring the frame maintains its structural integrity during regular use. This durability is especially important for bicycles used in challenging conditions, such as mountain biking or long-distance touring.

Manufacturers also use these compounds to enhance the protective coatings applied to bike frames. A polished surface allows coatings to adhere more effectively, providing an additional layer of defense against wear and tear.

Contribution to Performance and Aerodynamics

Buffing and polishing compounds improve not only the appearance and durability of bike frames but also their performance. A polished frame reduces air resistance, allowing the bicycle to move more efficiently. This aerodynamic advantage is crucial for competitive cyclists who need every edge to achieve faster speeds.

The smooth finish achieved through buffing minimizes drag caused by rough surfaces. This improvement in aerodynamics translates to better energy efficiency, making the bicycle easier to ride over long distances.

Polishing also ensures that components like handlebars, forks, and other metal parts integrate seamlessly with the frame, further enhancing performance.

By refining the surface of bike frames and their components, manufacturers create products that excel in both form and function.

Preparing Bike Frames for a Perfect Polish

Cleaning and Pre-Treatment Techniques

Proper cleaning and pre-treatment lay the foundation for a flawless bike frame finish. The process begins with disassembling the frame and removing any attached components. This step ensures easier access to all surfaces. Older parts may require extra care during disassembly to avoid damage. Logos and coatings can be removed using steel wool or paint stripper, while anodized layers are stripped with products like Easy-Off Oven Cleaner. Adequate ventilation is essential when working with chemical strippers.

For frames requiring powder coating, the electrostatic method is highly effective. This technique ensures the powder adheres evenly to the metal surface before curing. Pre-treatment chemicals also play a crucial role in achieving a smooth and durable finish.

Identifying and Addressing Surface Imperfections

Surface imperfections, such as scratches or dents, must be addressed before polishing. Filing the entire frame lug is an effective way to smooth out rough areas. Starting with coarse files and gradually moving to finer ones ensures a consistent finish. Sandpaper is another essential tool, with grits ranging from 120 to 1500. Alternating sanding directions prevents grooves from forming.

Experienced technicians often specialize in cosmetic repairs, ensuring high-quality results. Using high-grade products and techniques, they achieve a flawless finish that enhances the bike’s overall appearance. Positive customer reviews and before-and-after comparisons highlight the effectiveness of these methods.

Essential Tools for Frame Preparation

Preparing a bike frame for polishing requires a variety of tools. Coarse and fine files, sandpaper, buffing wheels, and emery cloth are indispensable for smoothing and refining the surface. Additional tools like hex wrenches, calipers, and torque wrenches help with disassembly and reassembly of components. Clean cotton rags and nitrile gloves ensure a clean and safe working environment.

A repair stand provides stability during the preparation process, while a flashlight or headlamp improves visibility in hard-to-reach areas. Bicycle-specific grease and chain lubricant are also essential for reassembling parts after polishing. These tools and materials ensure the frame is ready for a perfect polish.

Buffing and Polishing Techniques for Bike Frames

Types of Buffing and Polishing Compounds

Buffing and polishing compounds are essential for achieving a flawless finish on bike frames. These compounds come in various forms, each designed for specific purposes and materials. For instance, solid aluminum frames often require specialized compounds to bring out their natural shine. Users frequently discuss the satisfaction of polishing aluminum, emphasizing the importance of investing in the right materials.

A common setup for polishing includes three buffing wheels paired with three different compound sticks. This combination offers a cost-effective solution for achieving a professional-grade finish. Polishing compounds, often referred to as “rouges,” are available in different grades and colors. Each type serves a unique purpose, such as removing scratches, smoothing surfaces, or adding a final layer of shine.

Manufacturers carefully select compounds based on the bike frame’s material and desired finish. For example, coarse compounds are ideal for removing deep imperfections, while finer rouges create a mirror-like polish. By understanding the properties of these compounds, technicians can tailor the process to meet specific requirements.

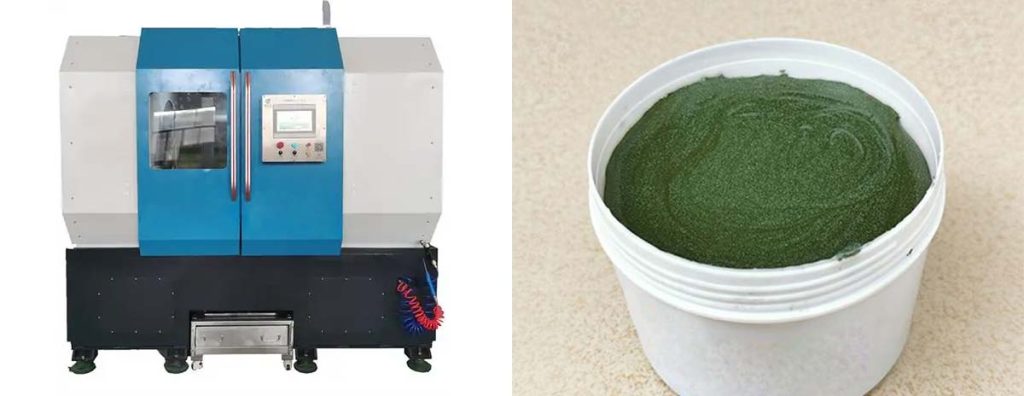

Using an Industrial Buffing Machine for Precision

An industrial buffing machine plays a crucial role in achieving precision during the polishing process. These machines are designed to handle large-scale operations, ensuring consistent results across multiple bike frames. Equipped with high-speed rotating wheels, they allow technicians to apply buffing and polishing compounds evenly on metal surfaces.

The machine’s adjustable settings provide flexibility, enabling users to control the pressure and speed for different parts of the frame. For instance, delicate components like the fork or handlebars require a gentler approach, while sturdier sections can withstand higher pressure. This level of control ensures that every part of the frame receives the attention it needs.

Industrial buffing machine also enhances efficiency by reducing manual labor. The machine streamlines the process, allowing manufacturers to polish multiple frames in less time. This not only improves productivity but also ensures a uniform finish across all products. By investing in advanced machinery, manufacturers can maintain high-quality standards while meeting production demands.

Achieving a Mirror-Like Finish with Advanced Techniques

Achieving a mirror-like finish requires a combination of advanced techniques and high-quality materials. The process begins with thorough surface preparation, ensuring that all imperfections are addressed before polishing. Technicians use progressively finer compounds to refine the surface, gradually enhancing its smoothness and shine.

One effective technique involves layering different polishing compounds. Starting with a coarse compound removes deep scratches, while subsequent layers of finer rouges create a flawless finish. Buffing wheels with varying textures are also used to achieve the desired result. For instance, softer wheels are ideal for the final stages of polishing, as they minimize the risk of scratches.

Attention to detail is critical during this process. Technicians must ensure that every part of the frame, including hard-to-reach areas, receives equal treatment. Tools like handheld buffers and specialized attachments help polish intricate components, ensuring a consistent finish.

The final step involves applying a protective coating to preserve the mirror-like shine. This coating not only enhances the frame’s appearance but also provides an additional layer of protection against wear and tear. By combining advanced techniques with high-quality materials, manufacturers can create bike frames that excel in both aesthetics and durability.

Benefits of Buffing and Polishing in Modern Manufacturing

Superior Aesthetics and Customer Satisfaction

Buffing and polishing elevate the visual appeal of bicycle frames, creating a flawless finish that attracts customers. The process removes imperfections from metal surfaces, leaving a smooth and reflective shine. This attention to detail enhances the overall appearance of the product, making it more desirable to consumers.

Customers often associate a polished frame with high quality and craftsmanship. Manufacturers who prioritize aesthetics build trust and loyalty among their buyers. A well-finished frame not only satisfies customer expectations but also encourages positive reviews and repeat purchases.

A polished aluminium frame, for instance, stands out with its sleek and modern design, appealing to riders who value both style and performance.

Increased Longevity and Durability of Bike Frames

Polishing improves the durability of bike frames by addressing surface imperfections that could lead to wear or corrosion. A smooth finish minimizes the accumulation of dirt and moisture, which can damage metal over time. This protective layer ensures the frame remains in excellent condition, even under challenging conditions.

The process also enhances the adhesion of protective coatings, providing an additional barrier against environmental factors. Polished components, such as handlebars and forks, resist scratches and abrasions, maintaining their structural integrity during regular use. This durability extends the lifespan of the bicycle, offering long-term value to riders.

Competitive Edge for Manufacturers in 2025

In 2025, manufacturers who invest in advanced buffing and polishing techniques gain a significant advantage in the market. A polished finish not only improves the product’s aesthetics but also highlights the brand’s commitment to quality. This attention to detail sets manufacturers apart from competitors, attracting discerning customers.

Efficient polishing processes reduce waste and production time, enabling manufacturers to meet growing demand without compromising quality. By offering durable and visually appealing products, they establish themselves as leaders in the industry. The integration of innovative techniques ensures they stay ahead in a competitive landscape.

Conclusion

Buffing and polishing compounds have revolutionized bike frame manufacturing by enhancing aesthetics, durability, and performance. In 2025, advancements in technology have made these processes faster, more precise, and environmentally friendly. Manufacturers now achieve superior finishes with reduced waste and energy consumption.

Adopting these techniques ensures that brands stay competitive while meeting the high expectations of modern consumers. By prioritizing quality and sustainability, manufacturers can create products that stand out in both form and function. Investing in these innovations is essential for long-term success in the industry.