Buffing polisher machine plays a vital role in the beauty industry by delivering flawless finishes. The machine ensures that the surface of beauty products appears smooth and visually appealing. High-quality surfaces significantly influence consumer perception and purchasing behavior.

- Products with polished surfaces are often associated with premium quality.

- Consumers evaluate the tactile feel and visual appeal of a product before making a purchase.

A polished surface not only enhances aesthetics but also increases the durability of beauty products. By using a buffing polisher machine, manufacturers can create items that stand out in a competitive market.

Key Takeaways

- Buffing polisher machine improves how beauty products look, making them more attractive and trusted by buyers.

- Shiny finishes can affect buying choices since people link glossy looks to luxury and good quality.

- Using buffing polisher machine helps companies keep a good name by giving the same high-quality results for all products.

- The machine helps the environment by cutting down on waste and making beauty products last longer with strong finishes.

- New features in buffing polisher machine let brands make special textures and finishes, helping them stand out in a crowded market.

The Role of Surface Quality in Beauty Products

Impact on Consumer Perception

Aesthetics and Purchasing Decisions

The surface of beauty products plays a critical role in shaping consumer purchasing decisions. Glossy finishes often symbolize luxury and high quality, while matte surfaces are associated with a natural and understated appeal. These surface characteristics influence how consumers perceive the product’s value. For example, a shiny lipstick case can create a sense of sophistication, while a matte foundation bottle may appeal to those seeking a minimalist aesthetic.

| Aspect | Influence on Consumer Perception |

|---|---|

| Glossiness | Associated with luxury and high quality |

| Mattness | Often perceived as more natural and understated |

Beauty products also impact self-esteem and self-perception. A well-designed product with a polished surface can enhance a consumer’s confidence, making them feel more connected to the brand. This connection often leads to repeat purchases and brand loyalty.

Tactile Experience and Perceived Value

The tactile experience of a product significantly affects its perceived value. Consumers often associate smooth, polished surfaces with innovation and premium quality. Studies show that glossy products are viewed as more innovative, which increases their overall value in the eyes of consumers. For instance, a sleek, polished compact mirror may feel more luxurious than one with a rough finish.

Manufacturers who use a buffing polisher machine ensure that their products achieve the desired surface quality. This precision not only enhances the product’s shine but also elevates its perceived worth. By delivering consistent results, these machines help brands partner with brands that prioritize quality and innovation.

Connection to Brand Reputation

Quality as a Reflection of Trust

The surface quality of beauty products directly reflects a brand’s commitment to excellence. Consumers often associate flawless finishes with trustworthiness. When a product looks and feels premium, it reassures buyers about the brand’s dedication to delivering high-quality items. For example, a skincare jar with a polished surface conveys reliability and care in its production.

Risks of Poor Finishes for Brand Image

Poor surface finishes can harm a brand’s reputation. Scratches, uneven textures, or dull surfaces may lead consumers to question the product’s quality. These imperfections can create doubts about the brand’s attention to detail and overall reliability. In a competitive market, such flaws can drive customers to seek alternatives.

By investing in advanced tools like a buffing polisher machine, brands can avoid these risks. These machines ensure that every product meets high standards, helping brands maintain their reputation and stand out in the beauty industry.

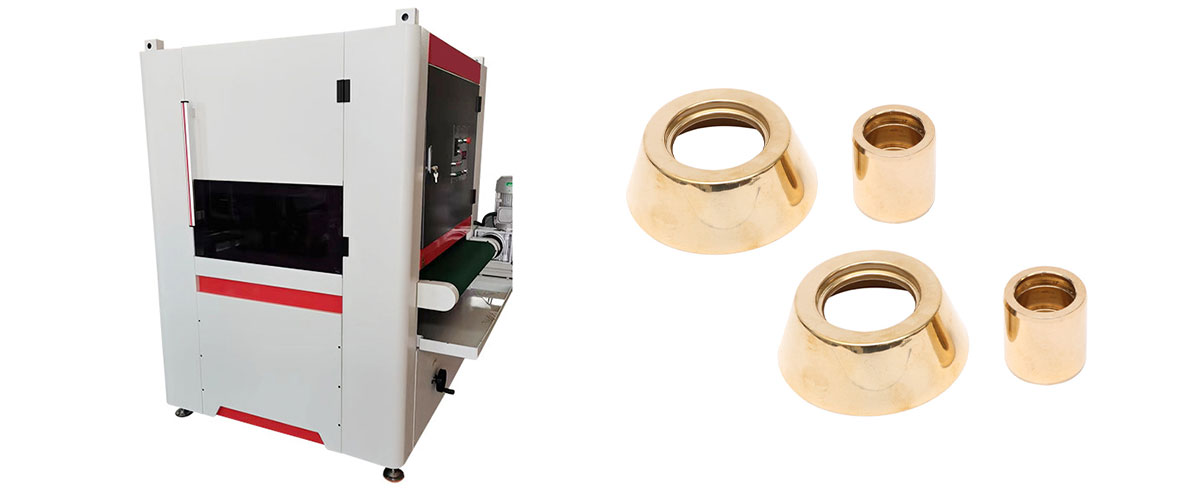

How Does Buffing Polisher Machine Work?

Technology and Functionality

Key Components and Their Roles

Buffing polisher machine relys on advanced components to deliver precise results. The machine often features a wide traversing buffing head, which ensures even coverage across the surface of products. Interchangeable work platens improve part handling, allowing manufacturers to polish various materials efficiently. Operators benefit from a programmable control system equipped with a CRT screen, simplifying operation and monitoring. Additionally, an automatic multiple spray gun compound system applies polishing compounds during operations like “cut and color” buffing. The entire machine is enclosed in a sheet metal housing to maintain controlled environmental conditions. This design ensures consistent performance and protects the machine from external factors.

Process of Achieving a Polished Finish

Achieving a polished finish involves several steps tailored to the material being polished. For example, when working with metal, the process begins with preparation, where grime and dirt are removed using a cleaning agent. Grinding follows, eliminating surface imperfections and rough edges. Sanding comes next, using wet-dry sandpaper with grits ranging from 400 to 1500 to create a smooth surface. Finally, a polishing compound is applied, and the surface is buffed with a polishing wheel or cloth to achieve a final finish. This process ensures that products not only look appealing but also feel smooth to the touch.

Benefits for Manufacturers

Consistent, High-Quality Results

Buffing polisher machine enables manufacturers to achieve consistent, high-quality finishes across all products. Automotive professionals use these machines to eliminate surface imperfections and create premium finishes on vehicles. Jewelry manufacturers rely on them to polish precious metals and gemstones, enhancing their shine and intricate details. Similarly, woodwork professionals use these machines to refine wooden surfaces, ensuring a flawless appearance. This consistency builds trust among consumers and reinforces a brand’s reputation for quality.

Time and Cost Efficiency

The machine streamlines the polishing process, saving time and reducing costs for manufacturers. The programmable control system allows operators to automate tasks, minimizing manual labor. Features like interchangeable work platens and automatic spray gun systems further enhance efficiency by reducing downtime between operations. By investing in a buffing polisher machine, manufacturers can produce polished products faster without compromising on quality. This efficiency translates to increased productivity and profitability, making the buffing polisher machine an essential tool in the beauty industry.

Creating a High-End Brand Image with Buffing Polisher Machine

Enhancing Product Appeal

Polished Surfaces in Premium Design

Polished surfaces play a pivotal role in creating a premium design for beauty products. A buffing polisher machine ensures that every product achieves a flawless finish, enhancing its visual and tactile appeal. Smooth and glossy surfaces often evoke a sense of luxury, while matte finishes cater to consumers seeking a minimalist aesthetic. These polished designs not only attract attention but also communicate the quality and care invested in the product’s creation.

The use of a polishing compound during the process further refines the surface, adding a radiant shine or a velvety texture, depending on the desired outcome. This attention to detail elevates the product’s overall presentation, making it more desirable to consumers who value aesthetics and functionality.

Examples of Beauty Products Benefiting from Buffing

Many beauty products rely on polished finishes to stand out. Lipstick cases, for instance, often feature sleek, reflective surfaces that exude sophistication. Compact mirrors benefit from a smooth, polished exterior that enhances their portability and elegance. Skincare jars and bottles with refined finishes not only look appealing but also feel premium in the hands of consumers. These examples highlight how polishing transforms everyday items into luxurious products that resonate with high-end branding.

Competitive Differentiation

Flawless Finishes as a Unique Selling Point

Flawless finishes achieved through buffing polisher machine serve as a unique selling point for brands. These machines refine materials like precious metals, gemstones, and natural stones, enhancing their aesthetic appeal. The table below illustrates how different materials benefit from polishing:

| Material Type | Benefit of Buffing Machines |

|---|---|

| Precious Metals | Polishes and refines metals like gold, silver, and platinum, enhancing aesthetic appeal. |

| Gemstones | Shapes and smoothens stones for desired luster, contributing to intricate detailing. |

| Wooden Materials | Improves surface quality and aesthetic appeal of both soft and hardwood. |

| Natural Stones | Enhances appearance of granite and marble for various applications. |

By offering products with impeccable finishes, brands can differentiate themselves in a crowded market. These polished surfaces not only attract attention but also build trust among consumers who associate quality with reliability.

Case Studies of Successful Brands

Several successful brands have leveraged buffing polisher machine to enhance their market position. A luxury skincare brand, for example, used these machines to create polished glass jars with a radiant shine, reinforcing their premium image. Another cosmetics company introduced lipstick cases with a mirror-like finish, making them both functional and visually stunning. These examples demonstrate how investing in polishing technology helps brands achieve a competitive edge while maintaining their commitment to quality.

Broader Impacts of Buffing Polisher Machine on the Beauty Industry

Supporting Sustainability

Reducing Waste Through Precision

Buffing polisher machine contributes to sustainability by minimizing material waste during the production process. The advanced technology ensures precise polishing, reducing the need for repeated attempts to achieve the desired surface quality. This precision allows manufacturers to use fewer raw materials, which helps conserve resources. For example, when polishing metal or glass surfaces, the machine’s accuracy prevents unnecessary material removal, preserving the integrity of the product. By reducing waste, brands can align with eco-conscious consumer values and promote sustainable practices in the beauty industry.

Extending Product Lifespan with Durable Finishes

Durable finishes created by buffing polisher machine enhance the longevity of beauty products. A polished surface resists wear and tear, maintaining its appearance and functionality over time. For instance, a compact mirror with a smooth, polished exterior is less likely to develop scratches, ensuring it remains visually appealing for longer periods. This durability reduces the frequency of product replacements, which benefits both consumers and the environment. Brands that prioritize long-lasting products can build trust with their audience while contributing to a more sustainable future.

Driving Innovation

Enabling New Textures and Finishes

Advancements in buffing polisher machine technology have enabled manufacturers to explore innovative textures and finishes. Features like programmable controls and structured abrasives allow for precise customization, resulting in unique surface qualities. The table below highlights how these advancements impact textures and finishes:

| Advancement Type | Impact on Textures and Finishes |

|---|---|

| Machine flexibility | Enables rapid changeover and adaptation to different finishes |

| Programmable controls | Allows for precise control over polishing processes |

| Structured abrasives | Provides uniform fine finishes and reduces operational costs |

| Automated systems | Enhances part quality and consistency of finish |

These innovations allow brands to experiment with creative designs, offering products that stand out in the market. For example, a skincare jar with a velvety matte texture or a lipstick case with a mirror-like shine can captivate consumers and elevate the brand’s image.

Inspiring Creative Packaging Designs

Buffing polisher machine inspires brands to develop unique and eye-catching packaging designs. Polished surfaces provide a premium look that enhances the overall appeal of beauty products. A sleek, reflective finish on a perfume bottle, for instance, can evoke a sense of luxury and sophistication. Similarly, textured finishes can add a tactile element to packaging, making it more engaging for consumers. By enabling these creative possibilities, buffing polisher machine helps brands differentiate themselves and leave a lasting impression on their audience.

Conclusion

Buffing polisher machine plays a crucial role in enhancing the beauty industry. The machine enables brands to deliver products with exceptional surface quality, which elevates the appeal and durability. The machine helps brands establish a high-end image, fostering consumer trust and loyalty. The precision supports sustainable practices by reducing waste and extending product lifespans. Additionally, the machine drives innovation by enabling unique textures and finishes. Investing in this technology allows brands to maintain a competitive edge while meeting consumer expectations for premium products.