The plastic buffer polisher stands out as a highly efficient tool for removing impurities from plastic surfaces. Its innovative filtering device design ensures thorough cleaning by capturing even the smallest unwanted particles. This advanced mechanism works precisely to enhance the quality of processed materials. By combining modern engineering with precision, it achieves results that improve both surface texture and overall durability. Such efficiency makes it an essential solution for industries requiring impeccable plastic finishes.

Key Takeaways

- The plastic buffer polisher cleans surfaces, making them stronger and better.

- Taking care of the filter regularly helps it work well.

- New filters, like special materials and smart layers, catch dirt better.

- Using the polisher with water cleaning systems makes water cleaner and helps nature.

- It saves money by cutting waste and working faster, making it useful for businesses.

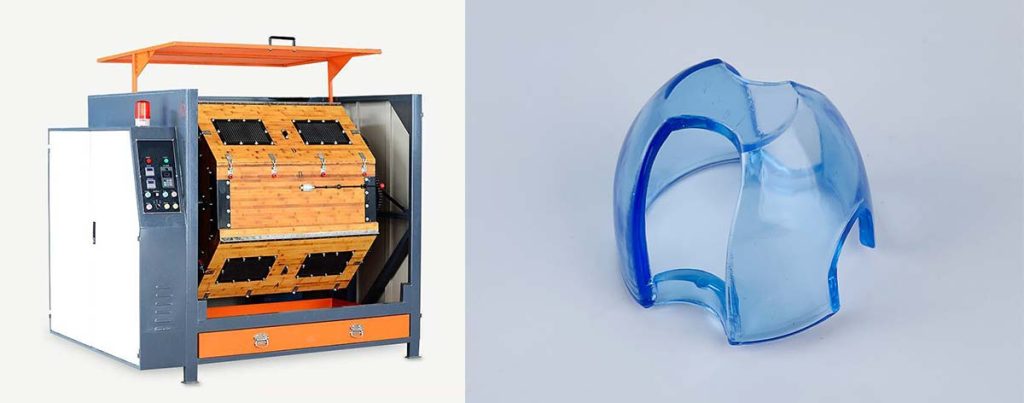

Design of the Plastic Buffer Polisher

The design of the plastic buffer polisher plays a critical role in its ability to remove impurities effectively. Its advanced filtration system incorporates cutting-edge technology and carefully engineered components to ensure optimal performance. By understanding the key elements of its filtering device and the latest innovations in filtration technology, industries can appreciate how this tool achieves such high levels of efficiency.

Key Components of the Filtering Device

The filtering device within the plastic buffer polisher consists of several essential components that work together to remove impurities. Each part is designed to maximize filtration efficiency and ensure durability during operation. Key components include:

- Filters: These are the core of the filtration system, responsible for capturing impurities of various sizes. High-quality filters ensure consistent performance and long-lasting results.

- Membranes: These thin layers act as selective barriers, allowing only clean particles to pass through while trapping contaminants. Advanced membranes improve the precision of the filtration process.

- Housing Unit: This component protects the filters and membranes, ensuring they remain intact during operation. It also facilitates easy maintenance and replacement.

- Flow Regulators: These devices control the speed and direction of the fluid passing through the filtration system, optimizing the removal of impurities.

Engineering studies have demonstrated the efficacy of these components through various tests. For example:

- Dry particle penetration tests evaluated the ability of filters to capture environmental particles.

- NaCl particle penetration tests showed filtration efficiency rates as high as 99.3%.

- Virus filtration efficiency tests confirmed the capability of membranes to trap microscopic contaminants effectively.

These results highlight the importance of each component in achieving a reliable and efficient filtration system.

Innovations in Filtering Device Technology

Recent advancements in filtering device technology have significantly enhanced the performance of the plastic buffer polisher. These innovations focus on improving impurity removal while maintaining cost-efficiency and ease of use. Notable developments include:

- Synthetic Media: The use of synthetic materials in filters has improved depth filtration, resulting in better impurity capture and reduced operational costs.

- Anion Exchange (AEX) Fiber Chromatography: This technology offers high separation precision and scalability, making it suitable for large-scale industrial applications.

- Tangential Flow Depth Filtration (TFDF): TFDF technology provides higher recovery rates and greater capacity compared to traditional depth filters, particularly for complex impurities.

- Functionalized Fiber Beds: These advanced filters trap contaminants more effectively, enhancing the overall performance of the filtration system.

- Sterile Filter Technology: A new innovation from Cytiva addresses premature filter blockage, enabling higher throughput without the need for oversized filters.

These advancements demonstrate how modern engineering continues to refine the design of filtration systems, ensuring they meet the evolving needs of industries. By integrating these technologies, the plastic buffer polisher achieves superior impurity removal, improved durability, and enhanced sterile filtration capabilities.

Impurity Removal Mechanisms

The plastic buffer polisher employs advanced impurity removal mechanisms to ensure optimal performance. These mechanisms rely on a combination of physical and chemical processes, each contributing to the effective elimination of contaminants. By understanding these processes, industries can better appreciate the role of this tool in achieving high-quality results.

Physical Processes In Impurity Removal

Physical processes form the foundation of impurity removal in the plastic buffer polisher. These processes involve the mechanical separation of contaminants from plastic surfaces or fluids. The filtration system plays a critical role in this stage, utilizing filters and membranes to trap impurities effectively.

The filters in the system capture particles of varying sizes, ensuring thorough removal of contaminants. High-quality membranes enhance this process by selectively allowing clean water or air to pass through while retaining unwanted particles. This selective filtration ensures high removal efficiency, even for microscopic impurities.

The design of the filtration system also incorporates flow regulators, which optimize the movement of water or other fluids through the filters. This controlled flow enhances the system’s ability to remove impurities consistently. Experimental data supports the effectiveness of these physical processes. For instance:

- The binding capacity of the HIC ligand at high salt concentrations matches that of conventional beads, demonstrating efficient impurity removal.

- Membrane adsorbers with phenyl ligands effectively eliminate hydrophobic impurities during monoclonal antibody production.

- Tests using 96-well plates and nanocapsules highlight the system’s ability to reduce buffer consumption and processing times.

These findings underscore the importance of physical processes in achieving reliable impurity removal. By leveraging advanced filtration technology, the plastic buffer polisher ensures consistent performance across various applications.

Chemical Interactions In The Polishing Process

Chemical interactions complement physical processes in the impurity removal mechanisms of the plastic buffer polisher. These interactions target specific contaminants, breaking them down or neutralizing their effects. This approach enhances the overall removal efficiency of the system.

During the polishing process, chemical agents interact with impurities to facilitate their removal. For example, certain chemicals bind to contaminants, making them easier to capture within the filtration system. This method proves particularly effective for removing dissolved impurities or those that are chemically bonded to the surface of materials.

The use of advanced membranes further enhances these chemical interactions. Functionalized membranes, designed with specific chemical properties, improve the system’s ability to target and remove challenging impurities. These membranes also contribute to sterile filtration, ensuring that the final product meets stringent quality standards.

Chemical interactions also play a vital role in wastewater treatment applications. The plastic buffer polisher integrates seamlessly with wastewater treatment systems, using its chemical processes to remove harmful substances from water. This integration not only improves water quality but also supports environmental sustainability by reducing the impact of industrial waste.

By combining physical and chemical processes, the plastic buffer polisher achieves a high level of impurity removal. This dual approach ensures that the system delivers consistent results, whether used in industrial applications, wastewater treatment, or bioprocessing.

Factors Influencing Effectiveness

Quality And Maintenance Of The Filtering Device

The effectiveness of the plastic buffer polisher heavily depends on the quality and maintenance of its filtering device. High-quality filters and membranes ensure consistent filtration and impurity removal. However, regular maintenance is equally critical to sustain optimal performance. Maintenance inspections play a vital role in identifying potential issues early and preventing costly repairs. These inspections also ensure that the equipment operates efficiently, minimizing downtime.

Key maintenance practices include:

- Evaluating the condition of filters and membranes to ensure they remain functional.

- Cleaning or replacing filters regularly to maintain filtration efficiency.

- Monitoring flow regulators to prevent blockages and optimize water flow.

The impact of maintenance on filter performance can be measured using technical metrics:

| Metric | Description |

|---|---|

| Mean Time Between Failures (MTBF) | Measures the average time between equipment failures, indicating reliability. |

| Mean Time to Repair (MTTR) | Indicates the average time taken to repair equipment, reflecting the efficiency of maintenance. |

| Availability | Represents the proportion of time equipment is operational, highlighting overall reliability. |

These metrics highlight how proper maintenance ensures the reliability and longevity of the filtration system, ultimately improving impurity removal efficiency.

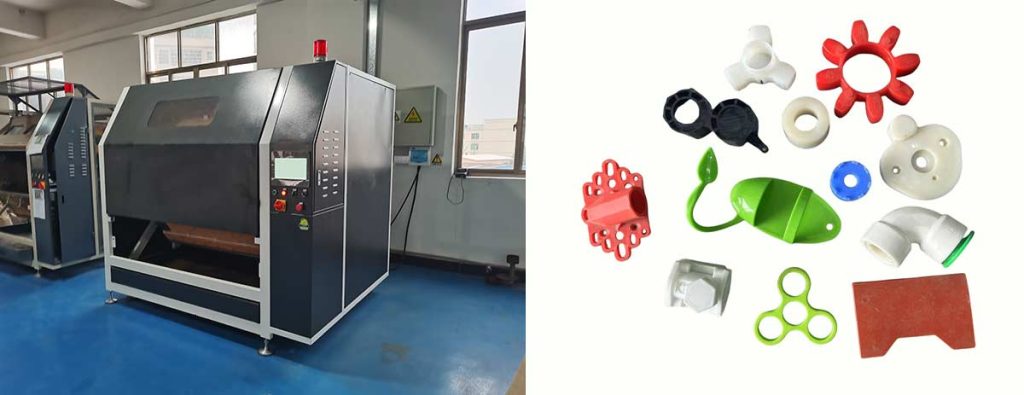

Type And Size Of Impurities

The type and size of impurities significantly influence the performance of the plastic buffer polisher. Larger particles are easier to capture, while smaller contaminants require advanced filtration technologies. Filters with high precision, such as those using synthetic media or functionalized membranes, are essential for removing microscopic impurities.

Impurities can be classified into physical, chemical, and biological categories. Physical impurities, such as dust or debris, are removed through mechanical filtration. Chemical contaminants, including dissolved substances, require chemical interactions for effective removal. Biological impurities, such as microorganisms, demand sterile filtration to ensure water quality.

In wastewater treatment, the diversity of impurities poses unique challenges. The integration of single-use technology in bioprocessing has enhanced the optimization of impurity removal. This approach ensures that the filtration process remains efficient, even when dealing with complex contaminants. Validation studies confirm that advanced filters improve removal efficiency, making them indispensable in industrial and environmental applications.

By addressing the quality of the filtering device and understanding the nature of impurities, industries can achieve superior results in water treatment and bioprocessing.

Benefits of Effective Impurity Removal

Improved Surface Quality And Durability

Effective impurity removal significantly enhances the surface quality of plastic products. The plastic buffer polisher ensures a smooth and consistent finish by eliminating contaminants that could compromise the material’s appearance or functionality. This improvement in surface quality directly impacts the durability of the product, as impurities often weaken the structural integrity of plastics.

Industries assess surface quality and durability using specific testing metrics. These include visual inspection to check for uniform finishes, touch inspection to detect imperfections, and function tests to ensure the product meets performance standards. The table below summarizes these metrics:

| Metric | Description |

|---|---|

| Visual Inspection | Check for a consistent finish across the entire surface of the part. |

| Touch Inspection | Feel the part for any remaining imperfections that may require additional polishing. |

| Function Test | Perform relevant tests to ensure performance is not compromised if a smooth surface is required. |

By maintaining high-quality surfaces, the plastic buffer polisher reduces the need for rework, saving time and resources. This ensures that products meet stringent industry standards while extending their lifespan.

Cost-Efficiency In Industrial Applications

The plastic buffer polisher offers cost-efficiency in industrial applications by optimizing impurity removal processes. Its advanced filtration system minimizes waste and reduces the need for additional polishing steps. This efficiency translates into lower operational costs and improved resource utilization.

Single-use technology plays a crucial role in achieving cost-efficiency. By integrating single-use filters, industries can streamline their processes and reduce maintenance expenses. These filters provide consistent filtration performance, ensuring reliable impurity removal without frequent replacements. This approach also supports wastewater treatment by improving water quality and reducing the environmental impact of industrial waste.

In wastewater treatment systems, the plastic buffer polisher enhances water quality by removing harmful contaminants. Its ability to handle diverse impurities makes it an essential tool for industries aiming to meet environmental regulations. The integration of single-use technology further simplifies the treatment process, making it more cost-effective and sustainable.

The combination of improved filtration performance and reduced operational costs highlights the economic benefits of using the plastic buffer polisher. Industries can achieve high-quality results while minimizing expenses, making it a valuable investment for various applications.

Role in Wastewater Treatment

Impact on Wastewater Quality

The plastic buffer polisher plays a vital role in improving wastewater quality by effectively removing impurities. Its advanced filtration system targets contaminants that degrade water quality, such as organic matter, chemicals, and microorganisms. By eliminating these impurities, the polisher ensures that treated water meets environmental standards and supports sustainable practices.

Performance evaluations highlight the impact of impurity removal on wastewater quality. Key indicators such as BOD (Biochemical Oxygen Demand) and COD (Chemical Oxygen Demand) measure the effectiveness of the treatment process. The BOD/COD ratio further assesses the biodegradability of wastewater. The table below summarizes these indicators:

| Indicator | Description |

|---|---|

| BOD | Measures the oxygen required by microorganisms to decompose organic matter. |

| COD | Quantifies the oxygen needed to oxidize all organic material in water. |

| BOD/COD Ratio | Indicates biodegradability; values above 0.6 suggest effective treatment. |

By reducing BOD and COD levels, the plastic buffer polisher enhances the overall quality of wastewater. This improvement ensures that treated water can be safely discharged or reused, minimizing environmental harm.

Integration With Wastewater Treatment Systems

The plastic buffer polisher integrates seamlessly with wastewater treatment systems, enhancing their efficiency and reliability. Its filtration technology complements existing processes, such as sedimentation and biological treatment, by removing fine particles and dissolved impurities. This integration ensures a comprehensive approach to wastewater filtration.

Industries benefit from the polisher’s ability to handle diverse impurities. Its advanced membranes and flow regulators optimize the removal of contaminants, even in complex wastewater streams. This capability makes it an essential component of modern treatment facilities. Additionally, the polisher supports single-use technology, reducing maintenance requirements and operational costs.

The integration of the plastic buffer polisher also contributes to environmental sustainability. By improving water quality, it reduces the ecological impact of industrial wastewater. This aligns with global efforts to conserve water resources and protect aquatic ecosystems.

Conclusion

The plastic buffer polisher demonstrates exceptional performance in impurity removal, thanks to its advanced design and innovative mechanisms. By effectively eliminating contaminants, it enhances the quality and durability of plastic products. Industries benefit from its ability to deliver consistent results, ensuring superior surface finishes and reliable performance. This tool plays a crucial role in improving industrial processes and wastewater treatment systems, making it an indispensable asset for achieving high standards in production and environmental sustainability.