Selecting the right industrial polishing system directly impacts efficiency and surface quality. Surface roughness measurements and material removal rates highlight how precision and speed vary across systems. For example, equipment selection criteria ensure compatibility with application needs, while power requirements and compliance with safety regulations influence operational success.

In 2025, advancements have redefined polishing technology. Increased automation, IoT integration, and AI-driven systems deliver high-quality finishes with minimal manual intervention. Robotic systems now dominate high-volume production, offering real-time monitoring and predictive maintenance. These innovations make it essential to align system choice with specific needs and budget constraints, ensuring long-term value and sustainability.

Key Takeaways

- Picking the right industrial polishing system improves work speed and surface look. Think about your specific needs before deciding.

- New automation and AI in 2025 make polishing better. These tools increase accuracy and cut down on manual work.

- Check if the industrial polishing system works with your materials. Different materials need different methods for the best finish.

- Look at both upfront costs and future savings. Strong, energy-saving systems can save money over time.

- Learn about safety and environmental rules. Eco-friendly systems follow rules and make your brand look good.

Overview of Industrial Polishing System in 2025

Advancements in Polishing Technology

In 2025, technological advancements have revolutionized the industrial polishing system, enhancing both efficiency and precision. Automated polishing systems now offer greater flexibility, enabling rapid changeovers that minimize downtime. Structured abrasives have emerged as a game-changer, delivering uniform finishes while reducing the number of sequential steps required. This innovation not only improves surface quality but also lowers operational costs.

Programmable finishing systems have addressed labor shortages by automating repetitive tasks. These systems streamline processes, ensuring consistent results across applications such as polishing stainless steel or preparing surfaces for high-precision industries. Polishing equipment has also benefited from these advancements, offering improved durability and performance for large-scale projects.

Trends in Industrial Polishing System

The industrial polishing system market continues to grow, with projections indicating a rise from USD 4.5 billion in 2023 to USD 7.8 billion by 2032. This growth reflects a compound annual growth rate (CAGR) of 6.2%. Industries such as automotive and electronics are driving demand for superior surface finishes, while aerospace and medical sectors require high-precision polishing solutions.

Automation and robotics remain key trends, enhancing productivity and reducing human error. Innovations in abrasive materials and robotic systems have further improved the efficiency of polishing machines. Additionally, the market has seen a shift toward eco-friendly and energy-efficient solutions, aligning with global sustainability goals. Polishing equipment and systems for polishing stainless steel now incorporate these features, making them more appealing to environmentally conscious industries.

The Role of Automation and AI

Automation and AI have become integral to modern polishing systems, transforming how industries achieve consistent and high-quality finishes. Automated systems ensure precise control over force and speed, delivering uniform results even for complex objects. Robotic polishing has significantly reduced cycle times, particularly in post-finishing processes like paint repair.

AI integration has enhanced operational control, enabling predictive maintenance and real-time monitoring. These features improve productivity and reduce downtime, making systems more reliable. For example, in metal polishing, automated systems ensure consistent quality while minimizing material waste. Polishing equipment also benefits from AI-driven adjustments, optimizing performance for diverse surface conditions.

The integration of automation and AI not only improves efficiency but also ensures compliance with industry standards, making these systems indispensable for modern manufacturing.

Types of Industrial Polishing System and Their Applications

Mechanical Polishing System

Applications in Metal Polishing

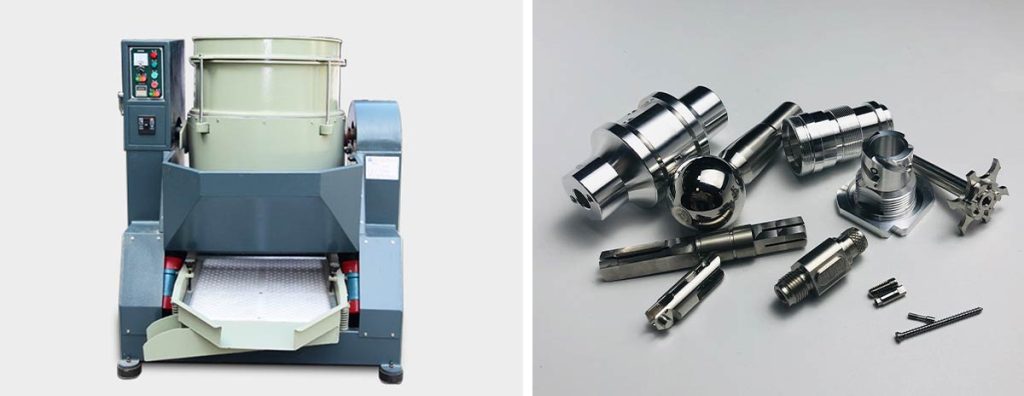

Mechanical polishing system is widely used for refining surfaces through abrasion, ensuring smoothness and uniformity. This method is particularly effective for polishing stainless steel, where achieving a mirror-like finish is critical. The metal polishing process involves using mould polishing tools and abrasive materials to remove imperfections, enhance durability, and improve the aesthetic appeal of components. Industries such as automotive and heavy machinery rely on this system to meet stringent surface quality standards.

Industries Benefiting from Mechanical Systems

Mechanical polishing systems serve diverse industries due to their versatility and efficiency. The table below highlights key applications and their benefits:

| Application | Benefits |

|---|---|

| Automotive Parts | Enhances surface finish, reduces friction, improves aesthetics, and increases corrosion resistance. |

| Building Materials | Achieves smooth surfaces, enhances durability, and eases maintenance. |

| Consumer Goods | Provides sleek finishes, improves usability, and enhances brand image. |

| Heavy Machinery | Reduces friction, increases durability, and improves functionality under heavy loads. |

| Industrial Equipment | Ensures performance and reliability in pumps, valves, conveyors, and robotic systems. |

Chemical Polishing System

Precision Applications

Chemical polishing system excels in applications requiring precision and uniformity. This method is ideal for polishing stainless steel components with intricate geometries, where mechanical methods may struggle. It is commonly used in industries like electronics and medical devices, where ultraclean surfaces and enhanced corrosion resistance are essential.

Pros and Cons

Chemical polishing offers several advantages but also comes with limitations. The table below provides a detailed comparison:

| Advantages of Chemical Polishing | Limitations of Chemical Polishing |

|---|---|

| Can polish complex shapes | Inconsistent brightness |

| Highly efficient for multiple parts | Difficult to heat solution |

| Requires less specialized equipment | Hard to adjust and regenerate |

| Good corrosion resistance | Emits harmful substances |

This system is cost-effective for high-volume production but requires careful handling to mitigate environmental and safety concerns.

Electrochemical Polishing System

Medical and Aerospace Applications

Electrochemical polishing system is indispensable in industries demanding high precision and surface quality. The medical sector uses this system to polish surgical instruments and implants, ensuring hygiene and biocompatibility. In aerospace, it enhances the performance and reliability of critical components by delivering superior finishes and reducing surface irregularities.

Surface Quality and Corrosion Resistance

This system provides unmatched surface quality and corrosion resistance, making it ideal for polishing stainless steel and other metals exposed to harsh environments. The table below outlines industries that heavily rely on electrochemical polishing systems and their reasons for preference:

| Industry | Reason for Use |

|---|---|

| General Fabrication | Enhances surface quality and performance |

| Marine | Improves corrosion resistance |

| Aerospace | Ensures precision and reliability |

| Automotive | Increases durability and aesthetic appeal |

| Pharmaceutical and Medical | Critical for hygiene and performance |

| Petrochemical | Enhances resistance to harsh environments |

| Food and Beverage Service | Ensures safety and cleanliness |

| Furniture | Improves visual appeal |

| Appliance | Enhances durability and aesthetic quality |

Electrochemical system also reduces material waste, making them a sustainable choice for industries prioritizing environmental responsibility.

Robotic Polishing System

High-Volume Production

Robotic polishing system excels in high-volume production environments, where efficiency and consistency are critical. These systems automate repetitive tasks, reducing reliance on manual labor and ensuring uniform results. Industries such as automotive and electronics benefit significantly from their ability to handle large-scale operations.

The table below highlights the key advantages of robotic polishing systems in high-volume production:

| Benefit | Description |

|---|---|

| Efficiency | Automated polishing is highly efficient for processing large orders, ensuring a consistent finish. |

| Consistency | The system applies consistent force and maintains constant rotational speed, leading to uniform results. |

| Speed | Robotic systems can remove material faster with reduced error rates compared to manual processes. |

By integrating robotic systems, manufacturers can achieve faster turnaround times while maintaining the quality of the metal finishing process. These systems also enhance the performance of mould polishing tools, ensuring precise results for intricate designs.

Smart Manufacturing Integration

Robotic polishing systems play a pivotal role in smart manufacturing. They integrate seamlessly with IoT-enabled devices, allowing real-time monitoring and data analysis. This connectivity enables predictive maintenance, reducing downtime and extending the lifespan of equipment.

For example, a metal polishing machine equipped with sensors can adjust its parameters automatically based on the material being processed. This adaptability ensures optimal performance across various applications, from polishing stainless steel to refining complex molds. Additionally, robotic systems enhance the functionality of mould polishing machines by automating adjustments, further improving efficiency.

The integration of robotic polishing systems into smart manufacturing environments not only boosts productivity but also aligns with sustainability goals by minimizing material waste.

Hybrid Polishing System

Combining Techniques for Complex Needs

Hybrid polishing system combines multiple polishing techniques to address complex requirements. The system integrates mechanical, chemical, and electrochemical methods, offering unparalleled flexibility. For instance, a hybrid system may use mechanical abrasion for initial material removal and chemical polishing for achieving a mirror-like finish.

This approach is ideal for industries requiring high precision and versatility. Aerospace and medical sectors often rely on hybrid systems to meet stringent surface quality standards. By combining techniques, these systems optimize the use of mould polishing tools, ensuring superior results for intricate components.

Examples of Hybrid Applications

Hybrid polishing systems find applications in diverse industries. In the automotive sector, they refine engine components to enhance performance and durability. In electronics, they polish delicate parts to achieve smooth surfaces essential for conductivity.

Another example involves the production of surgical instruments. A hybrid system may use mechanical polishing for shaping and electrochemical polishing for achieving biocompatibility. This combination ensures the highest standards of hygiene and functionality.

Hybrid system provides a comprehensive solution for industries with complex polishing needs, delivering precision and efficiency in a single platform.

Key Factors to Consider When Buying an Industrial Polishing System

Material Compatibility

Matching Systems to Materials

Choosing the right industrial polishing system requires careful consideration of material properties. Each material, whether metal, concrete, or composite, reacts differently to polishing methods. For instance, polishing stainless steel demands systems that can handle its hardness and corrosion resistance. Equipment selection should align with surface treatment requirements to ensure effective polishing. Performance data, such as abrasion rates and finish quality, helps in making informed decisions.

Avoiding Damage or Inefficiency

Using the wrong system can lead to material damage or inefficiency. A metal polishing machine designed for softer metals may fail to achieve a mirror finish on stainless steel. Similarly, concrete polishing equipment must match the density and texture of the flooring to avoid uneven results. Manufacturers should evaluate the compatibility of mould polishing tools and other accessories to prevent operational setbacks.

Production Speed and Volume

Evaluating System Capacity

Production demands vary across industries, making system capacity a critical factor. High-volume operations, such as automotive manufacturing, benefit from robotic systems that streamline the metal polishing process. Concrete polishing equipment packages designed for large-scale projects ensure consistent results without frequent downtime. Evaluating system capacity ensures that production goals align with operational capabilities.

Balancing Speed and Quality

Balancing speed and quality requires a strategic approach. Industry best practices and benchmarks guide system development, reducing trial-and-error. Manufacturers should treat each adjustment as a hypothesis, testing and validating changes to optimize performance. For example, a metal polishing machine can maintain speed without sacrificing quality by iterating based on feedback. This approach ensures that both production efficiency and surface preparation standards are met.

Surface Quality Requirements

Industry Standards for Finishes

Surface quality standards play a pivotal role in system selection. ISO 1302 and ISO 25178 provide guidelines for surface texture and 3D characterization, essential for industries like aerospace and additive manufacturing. ASME B46.1 outlines measurement methods that impact the functionality of machined parts. These standards ensure that polishing stainless steel or other materials meets precise industry requirements.

Precision Needs

Precision is vital for applications requiring flawless finishes. Medical devices, aerospace components, and polished concrete flooring demand systems capable of achieving exact specifications. A concrete grinder buying guide can help identify equipment that meets these needs. Similarly, types of polishing machines designed for intricate tasks ensure that even the most complex surfaces receive the required attention to detail.

Understanding these factors to consider when buying ensures that the chosen system aligns with production needs, material properties, and industry standards.

Cost and Budget Considerations

Initial Investment vs. Long-Term Savings

Evaluating the cost of an industrial polishing system requires a comprehensive approach. The initial investment includes the upfront cost of equipment, which varies based on system size, automation level, and features. For instance, robotic systems with advanced automation may demand higher initial spending but offer significant long-term benefits.

Long-term savings often outweigh the initial expense. Systems designed for durability reduce the frequency of replacements, while energy-efficient models lower operational costs. For example, concrete polishing equipment packages with advanced energy-saving features can minimize electricity consumption during the grinding and polishing process. Additionally, systems that deliver consistent quality reduce material waste, further enhancing cost efficiency.

Maintenance and Operational Costs

Maintenance and operational expenses significantly impact the total cost of ownership. Regular upkeep, such as filter replacements or lubrication, ensures optimal performance and extends equipment lifespan. Systems with predictive maintenance capabilities, often found in modern robotic models, help reduce unexpected downtime.

Operational costs include energy consumption and resource usage. For example, flooring equipment packages designed for polishing concrete often feature energy-efficient motors, reducing electricity costs. Manufacturers should also consider the cost of consumables, such as abrasives, which vary depending on the desired finish, whether a satin finish or a mirror finish.

Investing in a system with lower maintenance needs and efficient resource usage ensures long-term savings while maintaining high-quality surface finishing.

Environmental and Safety Concerns

Compliance with 2025 Regulations

In 2025, stricter environmental and safety regulations govern industrial processes. Polishing systems must comply with these standards to avoid penalties and ensure worker safety. For instance, systems used in the mould polishing process should minimize emissions and adhere to workplace safety guidelines.

Modern systems incorporate features that enhance compliance. Automated systems reduce manual intervention, lowering the risk of workplace injuries. Additionally, eco-friendly designs, such as those found in concrete polishing equipment packages, align with sustainability goals by reducing energy consumption and waste.

Reducing Environmental Impact

Reducing the environmental footprint of industrial polishing system is a priority for manufacturers. Systems designed for energy efficiency and minimal waste production contribute to sustainability. For example, a concrete grinder buying guide often highlights models with dust collection systems, which improve air quality and reduce particulate emissions.

Recycling consumables, such as abrasives, further minimizes waste. Additionally, systems that optimize the steps for polishing stainless steel reduce material loss, ensuring efficient resource utilization. By adopting these practices, industries can achieve polished concrete surfaces or other finishes while meeting environmental goals.

Prioritizing eco-friendly systems not only ensures compliance but also enhances brand reputation in an increasingly sustainability-focused market.

Conclusion

Understanding the advancements in industrial polishing system in 2025 is essential for making informed decisions. These innovations address challenges like rising quality standards, labor shortages, and environmental compliance. Flexible systems now handle diverse products efficiently, while programmable features improve safety and productivity. Organizations can leverage these advancements to meet operational needs effectively.

Aligning system choice with specific needs and budget ensures optimal outcomes. This approach maximizes efficiency by matching financial resources to operational goals. Continuous monitoring and timely adjustments based on real-world data further enhance competitiveness. A systematic decision-making process, supported by expert consultation, helps businesses navigate dynamic market conditions confidently.

By prioritizing flexibility, safety, and cost-effectiveness, industries can achieve superior results while meeting their unique needs.