Dust control plays a vital role in maintaining health and safety in workplaces that use auto buffing machines. Without proper measures, dust can accumulate, leading to respiratory problems, reduced equipment efficiency, and increased workplace hazards. Effective dust management ensures a cleaner environment, protects workers, and enhances productivity. By addressing this issue, businesses can create safer conditions while extending the lifespan of their machinery.

Key Takeaways

- Controlling dust is important for workers’ health and safety. It stops breathing problems and helps people work better.

- Dust collectors and vacuums catch dust right away. This keeps the air clean and makes machines last longer.

- Cleaning buffing machines often stops dust from piling up. It also makes polishing look better. Check machines regularly to keep them working well.

- Using polishing compounds that make less dust keeps the air safer. It also makes the finished work look nicer.

- Good ventilation systems, like Local Exhaust Ventilation (LEV), clean the air. They remove dust and lower health risks.

Common Sources of Dust in Auto Buffing Machines

Dust from Abrasive Materials

Abrasive materials used in auto buffing machines often generate significant amounts of dust. These materials, such as sandpaper or grinding wheels, wear down during use, releasing fine particles into the air. The harder the material, the more dust it produces. Workers exposed to this dust may face respiratory issues if proper precautions are not taken. Regularly inspecting and replacing worn abrasive tools can help reduce dust levels. Additionally, using high-quality abrasives designed for minimal dust production can further improve the workspace environment.

Dust Generated by Polishing Compounds

Polishing compounds are another major source of dust in auto buffing processes. These compounds, often applied to achieve a smooth finish, can break down into fine particles during use. The type of compound and the speed of the buffing machine influence the amount of dust generated. Research has shown that effective dust control systems can significantly reduce worker exposure to harmful particles. For example, a study comparing different dust control systems found that the Bull 1250 Dust Collection System effectively controlled exposure to respirable crystalline silica when used with the G-320D Concrete Polisher. However, other systems, like Local Exhaust Ventilation (LEV), required modifications to achieve similar results. High flow rate samplers also demonstrated improved precision in measuring dust levels, highlighting the importance of proper equipment in dust management.

| Equipment Used | Dust Control System | Findings |

|---|---|---|

| G-320D Concrete Polisher | Bull 1250 Dust Collection System | Controlled worker exposure to respirable crystalline silica, further evaluation recommended. |

| Prep-Master 2420 Concrete Polisher | Local Exhaust Ventilation (LEV) System | Needs modifications to reduce worker exposure to respirable crystalline silica. |

| Various Sites | High and Low Flow Rate Cyclones | High flow rate samplers collected significantly more respirable dust and quartz, indicating improved precision in measurement. |

Environmental Factors Contributing to Dust Accumulation

The surrounding environment plays a crucial role in dust accumulation. Poor ventilation can trap dust particles, making the air quality worse over time. Humidity levels also affect dust behavior. In dry conditions, dust particles remain airborne longer, increasing the risk of inhalation. On the other hand, high humidity can cause dust to settle on surfaces, leading to buildup on equipment and floors. Regular cleaning and installing proper ventilation systems can mitigate these environmental factors. Ensuring that the workspace remains free from unnecessary clutter also helps reduce dust accumulation.

Dust Control Strategies and Equipment

Using a Dust Collector for Effective Dust Removal

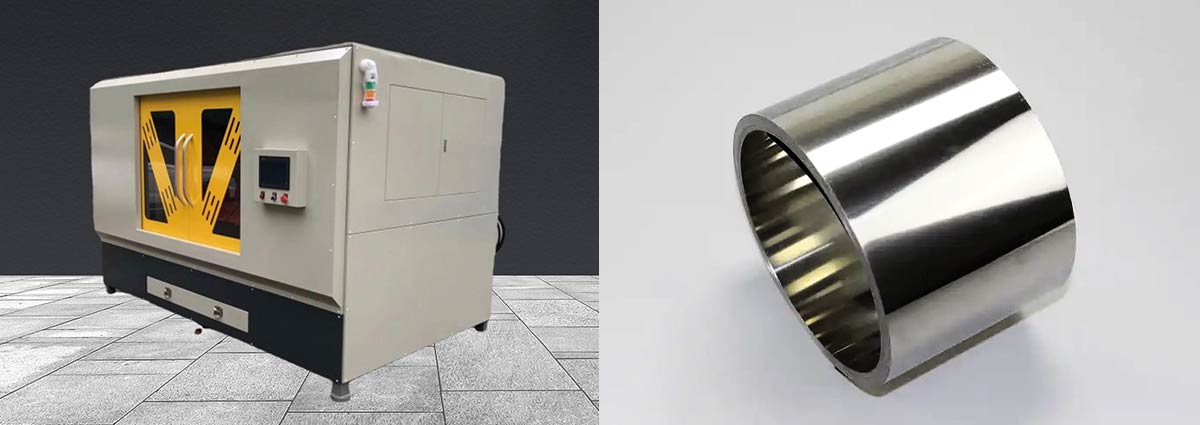

A dust collector is an essential tool for maintaining a clean workspace in industrial buffing machine. These systems capture dust particles directly at the source, preventing them from dispersing into the air. Source extraction systems, such as pre-separators, enhance the efficiency of dust collectors by reducing the amount of dust that reaches the main filtration unit. This not only improves air quality but also extends the lifespan of the equipment.

Studies have shown that using a shroud and vacuum with a dust collector can reduce airborne silica exposure by up to 94%, keeping it below NIOSH safety limits. Norton’s Fixed Abrasive Buff (FAB) technology further demonstrates the effectiveness of advanced dust control strategies. By reducing the need for polishing compounds by 60% to 90%, this innovation minimizes dust generation while improving the quality of the finish.

Benefits of Vacuum Systems in Auto Buffing Machines

Vacuum systems play a crucial role in dust control strategies for auto buffing machines. These systems remove dust particles from the workspace, creating a healthier environment for workers. A cleaner workspace reduces respiratory risks and enhances visibility, which improves safety during polishing tasks.

Performance metrics highlight the advantages of vacuum systems. For example, they minimize the time spent on cleaning, allowing workers to focus on polishing. This increases productivity and ensures a more efficient workflow. Additionally, vacuum systems prevent dust from settling on equipment, reducing maintenance needs and prolonging the life of industrial buffing machines.

| Benefit | Description |

|---|---|

| Cleaner working environment | Reduces respiratory risks and creates a healthier workspace. |

| Improved visibility | Enhances safety by reducing dust that can obscure vision. |

| Increased productivity | Minimizes time spent on cleaning, allowing for more efficient polishing processes. |

Air Filtration Systems for Cleaner Air

Air filtration systems are another effective solution for controlling dust in auto buffing operations. These systems work by capturing airborne dust particles, ensuring cleaner air for workers. Air cleaners, for instance, significantly reduce dust levels, enhancing worker safety and overall health.

Incorporating air filtration systems into dust control strategies offers long-term benefits. By maintaining cleaner air, these systems reduce the risk of respiratory issues and improve overall workplace conditions. Combining air filtration with other tools, such as dust collectors and vacuum systems, creates a comprehensive approach to dust management in industrial buffing machine environments.

Importance of Personal Protective Equipment (PPE)

Personal protective equipment (PPE) plays a critical role in safeguarding workers from the hazards associated with dust in auto buffing machines. Even with advanced dust control measures in place, some fine particles may still linger in the air, posing health risks. PPE serves as the last line of defense, ensuring workers remain protected in challenging environments.

Respirators are among the most essential PPE items for dust-heavy workplaces. These devices filter out harmful particles, preventing them from entering the respiratory system. Workers should select respirators certified by organizations like NIOSH to ensure maximum protection. Disposable masks may suffice for light-duty tasks, but reusable respirators with replaceable filters are better suited for prolonged exposure.

Safety goggles shield the eyes from airborne dust and debris. Buffing processes often generate fine particles that can irritate or damage the eyes. Workers should opt for goggles with a snug fit and anti-fog features to maintain visibility during tasks.

Protective clothing, such as coveralls, prevents dust from settling on the skin or being carried home. These garments should be made from materials that resist dust penetration and are easy to clean. Gloves also protect the hands from abrasive materials and polishing compounds.

Employers must provide proper training on the use and maintenance of PPE. Workers should understand how to wear equipment correctly and when to replace it. Combining PPE with effective dust control equipment creates a comprehensive safety strategy, reducing health risks and ensuring a cleaner workspace.

Tip: Regularly inspect PPE for wear and tear to maintain its effectiveness.

Best Practices to Minimize Dust When Polishing

Adjusting Buffing Techniques for Dust Reduction

Adjusting buffing techniques can significantly reduce dust and debris during polishing processes. Operators should optimize polishing cycles to minimize dust generation. For instance, using foam pads instead of wool pads helps contain dust more effectively. Additionally, products that condition polishing pads can further reduce dust when polishing.

A study comparing traditional buffing methods with Fixed Abrasive Buff (FAB) technology highlights the impact of technique adjustments. FAB technology reduces buffing compound usage by 10% to 40%, leading to measurable reductions in dust production.

| Buffing Method | Buffing Compound Usage | Dust Production Reduction |

|---|---|---|

| Traditional Buffing | 100% | High |

| Fixed Abrasive Buff (FAB) | 10% – 40% | Measurable Reduction |

These adjustments not only improve the working environment but also enhance the quality of the finish.

Choosing Low-Dust Polishing Compounds

Selecting low-dust polishing compounds is one of the best practices for dust management. These compounds produce less airborne dust and debris, creating a safer working environment. FAB wheels, for example, consume up to 90% less compound compared to traditional methods. They also leave minimal residue, reducing the need for frequent dust cleanup.

| Attribute | FAB Wheels | Traditional Buffing Methods |

|---|---|---|

| Compound Consumption | Up to 90% less | N/A |

| Cleaning Requirements | Minimal residue | Higher residue |

| Health & Safety | Less airborne compound | More airborne compound |

Low-dust compounds not only reduce dust but also improve surface finish consistency and buff durability. This approach ensures a cleaner workspace and better overall quality.

Regular Cleaning and Maintenance of Equipment

Regular cleaning and maintenance of the auto buffing machines are essential to control dust and debris. Dust buildup on equipment can reduce efficiency and compromise the working environment. Operators should clean machines after each use to prevent dust accumulation. Vacuum systems and air filtration tools can assist in thorough dust cleanup.

Routine maintenance also extends the lifespan of the equipment. Inspecting and replacing worn parts, such as abrasive pads, ensures optimal performance. Proper maintenance practices not only reduce dust but also improve the quality of polishing results.

Tip: Schedule regular maintenance checks to identify and address potential issues early. This proactive approach minimizes downtime and ensures a cleaner workspace.

Installing Proper Ventilation Systems

Proper ventilation systems play a crucial role in maintaining air quality in auto buffing machine workspaces. These systems remove airborne dust particles, ensuring a safer and cleaner working environment for operators. Without adequate ventilation, dust can accumulate, leading to health risks and reduced productivity.

Several types of ventilation systems are effective for dust control:

- Local Exhaust Ventilation (LEV): LEV systems capture dust directly at its source. They use hoods or ducts positioned near buffing machines to extract particles before they disperse into the air.

- Dilution Ventilation: This system reduces dust concentration by introducing fresh air into the workspace and exhausting contaminated air. It works best in large areas with moderate dust levels.

- Hybrid Systems: Combining LEV and dilution ventilation offers comprehensive dust control. These systems balance localized extraction with overall air circulation.

Installing ventilation systems requires careful planning. Operators should assess workspace size, machine placement, and dust generation rates. Regular inspections help monitor dust levels and ensure systems function efficiently.

Tip: Position ventilation ducts strategically to maximize dust removal and minimize airflow disruption.

Ventilation systems not only improve air quality but also enhance equipment performance. Dust-free environments reduce wear on machinery, extending its lifespan. Workers benefit from improved visibility, which increases safety during polishing tasks.

By integrating ventilation systems with other dust control measures, operators create a cleaner working environment that promotes health, safety, and productivity.

Conclusion

Effective dust control in auto buffing machines is essential for maintaining health, safety, and productivity. Identifying dust sources, using specialized equipment like dust collectors and vacuum systems, and following best practices such as regular cleaning and ventilation installation create a cleaner workspace.

Adopting these strategies offers measurable benefits:

- Prevent respiratory illnesses and meet workplace regulations.

- Reduce wear on tools and machines caused by dust buildup.

- Minimize cleanup time and improve visibility during operations.

Industry studies affirm these advantages. For example, a NIOSH evaluation demonstrated a 94% reduction in airborne silica exposure with dust control measures. Similarly, structured interventions significantly reduced quartz exposure among construction workers, showcasing the effectiveness of technical controls.

By implementing these strategies, operators can ensure a safer environment, reduce health risks, and enhance productivity over time.