Static dust often clings to plastic surfaces after polishing. This happens because the polishing process generates static electricity, which attracts dust particles from the surrounding air. Friction between the plastic and the polishing tool increases this effect. Using a plastic polish machine without proper precautions can worsen the issue. Anti-static products and controlled environments help reduce static buildup. Regular cleaning also prevents dust from settling on polished surfaces.

Key Takeaways

- Static dust sticks to polished plastic because of static electricity. Knowing this can help stop dust from gathering.

- Use anti-static sprays or creams to remove static charges. Applying them often keeps dust away and saves cleaning time.

- Keep humidity levels between 40% and 60% to lower static. Use a hygrometer to check the humidity easily.

- Clean properly before and after polishing for the best results. Use lint-free cloths and anti-static items to keep surfaces dust-free.

- Don’t polish too much to avoid static buildup. Follow the maker’s instructions and check the surface to keep it clear and less dusty.

Causes of Static Dust on Polished Plastic

How Static Electricity Forms During Polishing?

Static electricity forms when two materials interact, causing an imbalance of electrical charges. During polishing, the friction between the plastic surface and the polishing tool generates this imbalance. This phenomenon, known as the triboelectric effect, occurs because electrons transfer between the materials. Historical observations, such as the ancient Greeks noticing polished amber attracting straw, highlight the early understanding of static electricity. Modern examples, like the static cling of plastic wrap, demonstrate how this effect applies to everyday materials, including polished plastics.

The Role of Friction in Static Generation

Friction plays a critical role in creating static electricity during polishing. When the polishing tool rubs against the plastic, their surfaces deform at a microscopic level. This deformation leads to the generation of voltage, which contributes to static buildup. Research on the triboelectric effect shows that the resistance of materials to sliding motion, known as elastic shear, amplifies this process. The repetitive motion of polishing increases the contact between surfaces, intensifying the static charge. This explains why dust from polishing tends to cling stubbornly to plastic surfaces.

Environmental Factors That Contribute to Static Dust

Environmental conditions significantly influence static electricity and dust accumulation. Low humidity levels, for instance, make the air drier, which enhances the buildup of static charges. In contrast, higher humidity reduces static by allowing moisture to dissipate the charge. Airflow also plays a role; stagnant air allows dust particles to settle more easily on polished surfaces. Controlling these factors, such as maintaining moderate humidity and ensuring proper ventilation, can help minimize static dust after polishing.

Preventive Measures for Static Dust

Using Anti-Static Sprays and Creams

Anti-static sprays and creams are effective tools to reduce dust on polished plastic surfaces. These products work by neutralizing static charges, preventing dust particles from clinging to the surface. For example, users have reported that applying FK425 to half of their TV resulted in noticeably less dust on that side after a week. While not perfect, many reviews highlight that anti-static products significantly reduce dust accumulation.

| Feature | Description |

|---|---|

| Product | Endust for Electronics Multi-Surface Anti-Static Electronics Cleaner |

| Size | 8 oz Aerosol Spray |

| Key Benefits | Cleans surfaces, prevents static-charge build-up, alcohol-free, streak-free drying |

When choosing an anti-static product, consider its compatibility with the plastic polish machine and the surface being treated. Regular application ensures long-lasting results and minimizes the need for frequent dust cleanup.

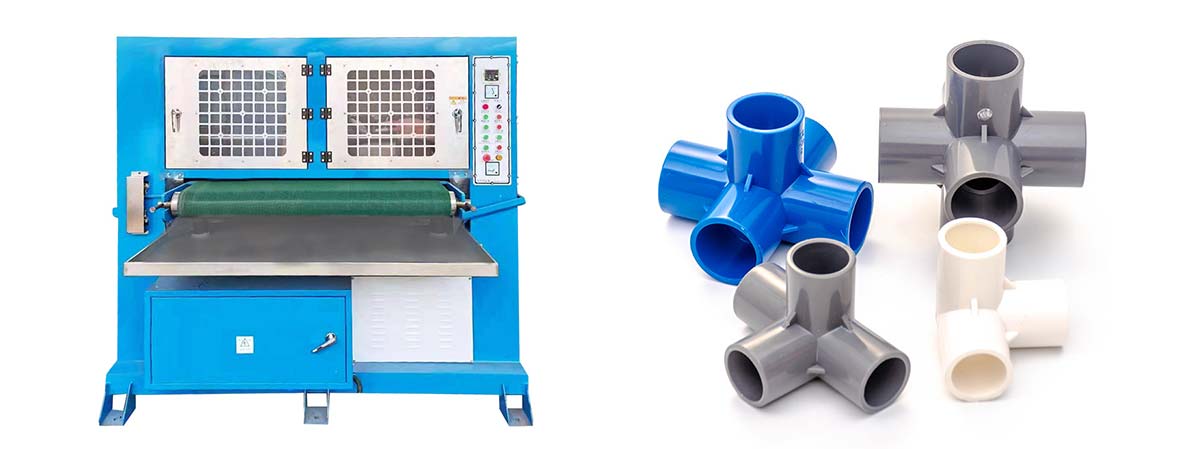

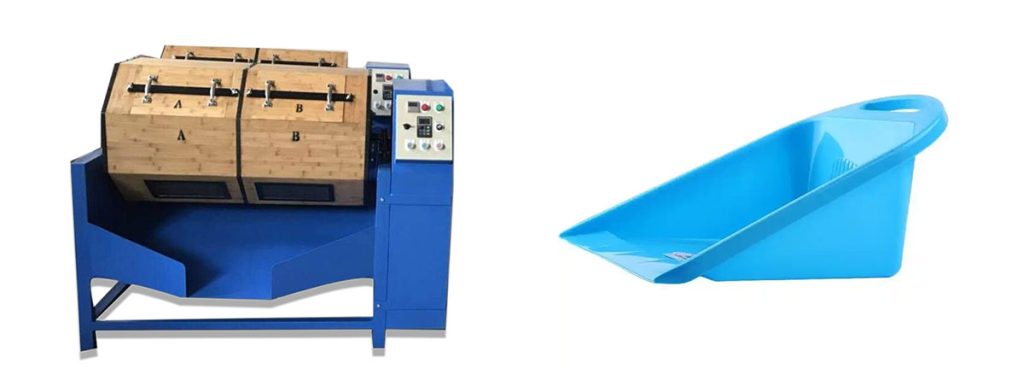

Selecting the Right Plastic Polish Machine

The choice of a plastic polish machine plays a crucial role in controlling static dust. Machines with antistatic properties are designed to reduce static electricity accumulation during polishing. These models often feature non-toxic and environmentally friendly materials, which improve operational safety and efficiency.

| Feature | Benefit |

|---|---|

| Antistatic properties | Reduces static electricity accumulation |

| Non-toxic and environmentally friendly | Improves operational safety and efficiency |

Selecting a machine with these features ensures a smoother polishing process and helps reduce dust buildup. Investing in a high-quality machine not only enhances the finish but also minimizes the time spent on dust cleanup.

Proper Cleaning Techniques Before and After Polishing

Proper cleaning techniques are essential to maintain a dust-free surface. Before polishing, clean the plastic surface with a lint-free cloth to remove any existing dust or debris. This step prevents particles from embedding into the surface during plastic polishing. After polishing, use an anti-static cloth or spray to wipe down the surface. This final step neutralizes any static charges generated during the process.

Tip: Avoid using abrasive cleaning tools, as they can damage the surface and increase static buildup.

Consistent cleaning before and after using the plastic polish machine ensures a polished surface remains dust-free for longer periods. Combining these techniques with anti-static products enhances overall effectiveness.

Controlling Humidity and Airflow During Polishing

Humidity and airflow play a significant role in reducing static dust during plastic polishing. Dry air increases static electricity, making dust particles cling to polished surfaces. Maintaining moderate humidity levels helps dissipate static charges. A hygrometer can measure indoor humidity, ensuring it stays between 40% and 60%. If the air is too dry, a humidifier can add moisture to the environment.

Proper airflow also minimizes dust accumulation. Stagnant air allows dust particles to settle on polished surfaces, while controlled ventilation keeps the air moving. Positioning fans or air purifiers near the workspace can help circulate air and reduce airborne dust. However, excessive airflow may scatter dust particles, so it’s essential to strike a balance.

Tip: Use an air purifier with a HEPA filter to trap dust particles effectively. This ensures cleaner air during the polishing process.

By managing humidity and airflow, users can create an environment that reduces static buildup and keeps polished surfaces cleaner for longer periods.

Grounding Plastic Surfaces to Reduce Static

Grounding plastic surfaces is an effective way to minimize static electricity during polishing. Static charges accumulate when surfaces lack a path to discharge. Grounding provides this path, neutralizing the charge and preventing dust from clinging.

To ground a plastic surface, users can attach an anti-static grounding strap or mat to the workspace. These tools connect to a grounded outlet, allowing static electricity to dissipate safely. For smaller items, conductive sprays or wipes can be applied to create a temporary grounding effect.

Note: Ensure the grounding tools are compatible with the materials being polished to avoid damage or interference with the process.

Grounding not only reduces static but also improves the overall polishing experience. It ensures a smoother finish and reduces the time spent cleaning dust from polished surfaces.

Maintenance Tips for Dust-Free Polished Plastic

Regular Cleaning with Anti-Static Products

Regular cleaning is essential to maintain the pristine appearance of polished polycarbonate surfaces. Anti-static products, such as sprays or wipes, help prevent dust from settling by neutralizing static charges. These products also simplify the cleanup process by reducing the frequency of dust accumulation.

To clean effectively, use a soft, lint-free cloth with an anti-static solution. Gently wipe the surface to remove any dust or debris. Avoid abrasive materials, as they can scratch the polished polycarbonate and increase static buildup. Consistent cleaning not only preserves the surface’s clarity but also extends the lifespan of the anti-static coating.

Tip: Schedule weekly cleaning sessions to ensure polished polycarbonate surfaces remain dust-free and visually appealing.

Storing Polished Plastic in Controlled Environments

Proper storage plays a crucial role in maintaining dust-free polished polycarbonate. Environmental factors, such as humidity and airflow, directly impact static buildup and dust attraction. Storing these items in controlled environments minimizes exposure to dust and static-inducing conditions.

Use storage containers with anti-static properties or line shelves with anti-static mats. Keep the storage area clean and free from excessive airflow, which can stir up dust. For optimal results, maintain a humidity level between 40% and 60% using a hygrometer. This range reduces static electricity and prevents dust from clinging to the surface.

Note: Avoid storing polished polycarbonate near heat sources or in areas with fluctuating temperatures, as these conditions can degrade the material over time.

Reapplying Anti-Static Coatings Periodically

Anti-static coatings lose effectiveness over time due to wear and environmental exposure. Reapplying these coatings ensures polished polycarbonate surfaces remain resistant to static and dust. Most anti-static sprays or creams are easy to apply and provide long-lasting protection.

Before reapplying, clean the surface thoroughly to remove any dust or residue. Apply the anti-static product evenly, following the manufacturer’s instructions. Allow the coating to dry completely before handling the item. Regular reapplication not only enhances dust resistance but also reduces the need for frequent cleanup.

Reminder: Check the product label to ensure compatibility with polished polycarbonate surfaces before application.

Avoiding Over-Polishing to Minimize Static Build-Up

Over-polishing plastic surfaces often leads to increased static electricity, which attracts dust particles. This happens because excessive polishing generates more friction, causing a higher buildup of static charges. Avoiding over-polishing not only reduces static but also preserves the surface’s optical clarity.

To minimize over-polishing, users should follow these practical steps:

- Use the Right Polishing Tools

Selecting tools designed for plastic surfaces ensures a balanced polishing process. Tools with adjustable speed settings allow users to control the intensity, preventing unnecessary friction that could compromise optical clarity. - Follow Manufacturer Guidelines

Every plastic polish product comes with specific instructions. Adhering to these guidelines helps achieve the desired finish without overworking the surface. For example, applying the polish in thin, even layers reduces the need for repeated passes. - Monitor the Surface Regularly

Observing the surface during plastic polishing helps identify when the desired level of clarity has been achieved. Over-polishing often results in a hazy or uneven finish, which diminishes optical clarity. Stopping at the right time prevents this issue. - Limit Polishing Frequency

Frequent polishing increases the risk of static buildup and surface wear. Scheduling polishing sessions only when necessary maintains the surface’s quality and reduces static-related problems.

Tip: Use a microfiber cloth to test the surface’s smoothness. If the cloth glides effortlessly, further polishing may not be needed.

By avoiding over-polishing, users can maintain the optical clarity of plastic surfaces while minimizing static buildup. This approach ensures a cleaner, dust-free finish and extends the lifespan of the polished material.

Conclusion

Static dust often poses challenges when using a plastic polish machine, but effective strategies can mitigate this issue. Understanding the causes of static electricity and applying preventive measures ensures polished surfaces remain clean and dust-free. Anti-static sprays, proper cleaning techniques, and environmental control play vital roles in reducing static buildup.

Adopting these practices has proven successful in various industries. For instance:

- Mining Company XYZ significantly reduced dust emissions and improved air quality by implementing effective dust control strategies.

- These measures created a safer environment and ensured compliance with regulations.

Regular maintenance, such as reapplying anti-static coatings and storing items in controlled environments, further enhances surface protection. Share your experiences or questions in the comments to help others overcome static dust challenges.