Reducing waste in buffing processes is critical for improving cost efficiency and sustainability. Excessive use of polish compound not only increases operational expenses but also reduces overall polishing effectiveness. Optimizing systems can significantly enhance compound savings by refining the application process. For example, studies highlight how adjusting coagulant doses minimizes sludge volume, cutting operational costs. Properly calibrated methods ensure consistent finishing results while reducing environmental impact. Buffing techniques help achieve the final desired result on any surface, whether polishing very hard materials or softer ones. Ultimately, a streamlined process boosts productivity and ensures a flawless final polish.

Key Takeaways

- Change system settings like flow rates and pressure levels. This helps use less polish and spreads it evenly.

- Pick good-quality polishing compounds for better results. They use less material, save money, and work faster.

- Add recycling systems to reuse polishing compounds. This cuts waste and helps the environment.

- Check and fix equipment often to avoid problems. This keeps it working well and saves polish.

- Teach workers the best ways to polish. Trained staff can work better and help the planet.

Optimize System Settings for Polish Compound

Adjust Flow Rates for Precision

Precise flow rate adjustments play a critical role in reducing waste during buffing compound application. By controlling the amount of liquid buffing compound dispensed, operators can ensure that only the necessary quantity reaches the surface. This minimizes excess usage and prevents uneven distribution. For example, studies have shown that maintaining consistent flow rates under the same operating conditions can significantly improve efficiency. The table below highlights how flow rate adjustments impact removal rates in a polishing process:

| Test | Flow Rate Conditions | Uranium Removal (%) | Gross Alpha Removal (%) |

|---|---|---|---|

| 1 | Same Operating Conditions | 58 – 91 | 33 – 87 |

These findings demonstrate that optimizing flow rates not only reduces waste but also enhances consistent finishing results. Operators should regularly monitor and adjust flow settings to achieve the final desired result on any surface.

Calibrate Pressure Levels to Minimize Overuse

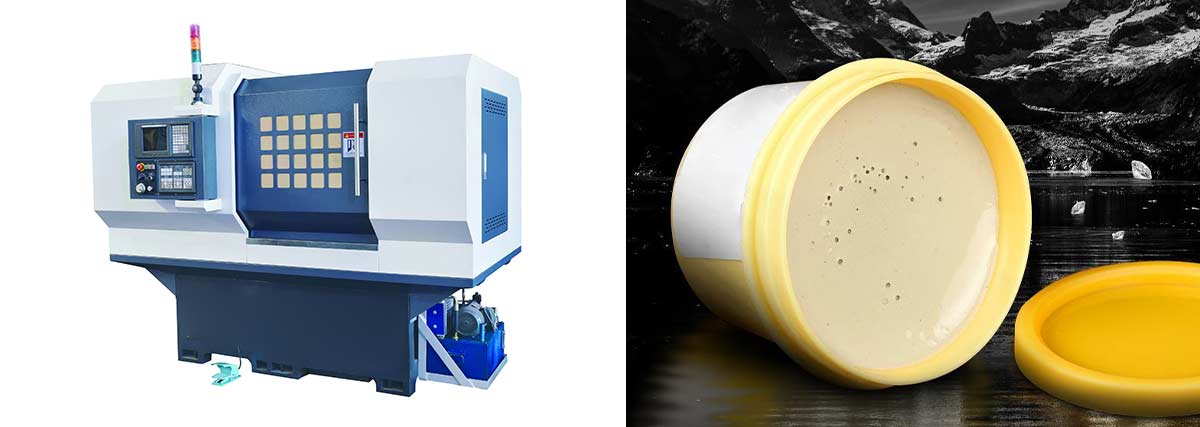

Pressure calibration is another essential factor in optimizing compound application methods. Excessive pressure during buffing can lead to overuse of the compound and uneven surface coverage. On the other hand, insufficient pressure may result in inadequate polishing. Industrial buffing machines equipped with adjustable pressure settings allow operators to fine-tune the application process. Regular calibration ensures that the pressure remains within optimal ranges, reducing waste and improving productivity. This method also helps maintain the longevity of equipment by preventing unnecessary wear and tear.

Fine-Tune Timing for Efficient Application

Timing adjustments are crucial for achieving efficiency in the polishing process. Over-application of the compound often occurs when the timing is not properly synchronized with the buffing motion. Operators should evaluate the duration of compound application to ensure it aligns with the surface area being polished. Automated systems can assist in maintaining precise timing, reducing the risk of overuse. Fine-tuning this aspect not only conserves resources but also ensures a flawless final finish. Consistent timing adjustments contribute to a streamlined process, enhancing overall productivity and achieving the final desired result.

Use High-Quality Polish Compound

Advantages of High-Quality Compounds in Waste Reduction

High-quality polishing compounds offer significant benefits in reducing waste during the buffing process. These compounds are designed to provide consistent performance, ensuring that less material is required for effective application. Their superior formulation minimizes the need for repeated buffing, which directly contributes to compound savings. Additionally, many high-quality compounds meet modern environmental standards, as their biodegradability is influenced by factors such as molecular weight, chain length, and functional groups. With increasing concerns about pollution, the demand for biodegradable compounds continues to grow. Local regulations are also pushing industries to adopt eco-friendly alternatives, further emphasizing the importance of using high-quality materials.

How Premium Compounds Improve Efficiency?

Premium polishing compounds enhance efficiency by delivering better results with less effort. Their advanced formulations ensure even application across the surface, reducing the likelihood of uneven finishes or the need for rework. This not only saves time but also improves overall productivity. High-quality compounds are also less prone to clogging equipment, which helps maintain a smooth polishing process. By reducing interruptions and ensuring consistent performance, these compounds allow operators to achieve the final desired result more effectively. Their ability to work efficiently on various surfaces, from hard metals to softer materials, makes them a versatile choice for different buffing applications.

Balancing Initial Costs with Long-Term Savings

While high-quality compounds may have a higher upfront cost, their long-term benefits often outweigh the initial investment. Polish compounds enhance the visual appeal of polished products, increasing their perceived value. They also improve product performance, leading to longer-lasting results and greater customer satisfaction. The table below highlights some key benefits of using premium compounds

| Benefit | Description |

|---|---|

| Enhanced visual appeal | Increases perceived value of products. |

| Improved product performance | Leads to longer-lasting and more effective products. |

| Increased customer satisfaction | Boosts brand reputation and customer loyalty. |

By reducing waste, improving efficiency, and delivering superior results, high-quality compounds contribute to significant savings over time. Their ability to streamline the buffing process ensures a more sustainable and cost-effective operation.

Implement Recycling Systems for Polish Compound

Overview of Recycling Systems in Polishing

Recycling systems play a vital role in reducing waste during buffing compound application. These systems are designed to recover and reuse materials, minimizing the need for fresh resources. Industry reports highlight their importance in addressing resource scarcity and reducing environmental impact. For example, the compound semiconductor wafer polishing systems report emphasizes recycling as a key strategy for companies to align with global sustainability goals. By incorporating recycling systems, manufacturers can innovate their production processes while fostering eco-friendly practices.

Modern recycling systems often include water recovery mechanisms and biodegradable polishing slurries. These advancements not only reduce waste but also respond to regulatory pressures and consumer demand for greener technologies. The CMP polishing and grinding equipment market report underscores the growing focus on eco-friendly processes, showcasing how recycling systems contribute to a more sustainable buffing process.

Benefits of Reusing Final Polishing Compound

Reusing the final polishing compound offers multiple benefits for manufacturers. It reduces the overall consumption of liquid buffing compound, leading to significant cost savings. Recycling systems allow operators to recover unused compound from the buffing process and reapply it efficiently. This approach minimizes waste and ensures consistent application across surfaces.

Environmental benefits are equally noteworthy. Reusing compounds decreases the volume of waste generated, reducing the strain on disposal systems. It also supports sustainability initiatives by lowering the carbon footprint of polishing operations. Manufacturers who adopt these practices often find themselves better positioned to meet regulatory requirements and enhance their reputation as eco-conscious businesses.

Best Practices for Recycling in Automatic Polishing Systems

Implementing recycling systems in automatic polishing systems requires adherence to best practices. Operators should regularly monitor equipment to ensure optimal performance and avoid contamination of recovered compounds. Proper filtration systems are essential for maintaining the quality of recycled materials. Manufacturers should also invest in advanced recycling technologies that integrate seamlessly with existing buffing systems.

Case studies provide valuable insights into effective recycling practices. For instance, solvent conservation and recycling techniques have proven successful in minimizing waste. The table below highlights documented examples of recycling strategies:

| Case Study | Description |

|---|---|

| Case Study #1 | CFC Reduction/Elimination in Electronics Cleaning |

| Case Study #2 | Using Industrial Hygiene Techniques to Monitor and Reduce Solvent Losses |

| Case Study #3 | Solvent Equipment Selection – A Case Study of Errors |

| Case Study #4 | Emissions Monitoring and Reduction |

| Case Study #5 | History of Equipment Upgrades |

| Case Study #6 | Solvent Conservation and Recycling |

By adopting these practices, manufacturers can optimize their buffing compound application process, reduce waste, and achieve a flawless final finish. Recycling systems not only enhance operational efficiency but also contribute to a cleaner and more sustainable environment.

Regular Maintenance and Calibration of Equipment

Preventative Maintenance to Avoid Waste

Preventative maintenance ensures that industrial polishing system operates efficiently and reduces unnecessary waste. Scheduled inspections and minor adjustments prevent equipment breakdowns, which can lead to overuse of the polish compound. For example, a textile mill that regularly services its looms avoids costly downtime during peak production seasons. Similarly, predictive maintenance uses data analytics to identify potential failures. An oil refinery monitors vibration patterns in centrifugal pumps to replace bearings before they fail catastrophically. These practices ensure that buffing systems remain operational and minimize waste during the application process.

Condition monitoring has become a vital tool in preventative maintenance. Real-time data about machinery conditions allows operators to identify issues early. This proactive approach ensures maintenance occurs before breakdowns, increasing operational uptime and reducing waste. By maintaining equipment regularly, manufacturers can achieve significant compound savings and improve the final finish on polished surfaces.

Importance of Calibration in Reducing Spillage

Calibration plays a crucial role in reducing spillage during the buffing process. Properly calibrated equipment ensures that the polish compound is applied evenly across the surface. This prevents over-application, which can lead to waste and uneven finishes. For instance, industrial buffing machines with adjustable settings allow operators to fine-tune the application process. Regular calibration ensures these settings remain accurate, optimizing the use of the compound.

Uncalibrated equipment often results in inconsistent application, leading to excessive use of resources. By calibrating machines regularly, manufacturers can maintain precise control over the buffing process. This not only reduces waste but also enhances the quality of the final polished surface. Calibration is a simple yet effective way to improve efficiency and achieve consistent results.

Common Maintenance Errors and How to Avoid Them

Maintenance errors can undermine the efficiency of buffing systems and increase waste. One common mistake is neglecting to clean equipment after use. Residual polish compound can clog machinery, leading to uneven application and higher resource consumption. Operators should clean machines thoroughly after each use to prevent this issue.

Another frequent error is skipping scheduled maintenance. Delaying inspections or repairs can result in equipment malfunctions, causing overuse of the polish compound. Adhering to a strict maintenance schedule helps avoid these problems. Additionally, using incorrect tools or techniques during maintenance can damage equipment. Operators should follow manufacturer guidelines and use appropriate tools to ensure proper care.

By addressing these errors, manufacturers can optimize their buffing systems, reduce waste, and achieve a flawless final finish. Regular maintenance and calibration are essential for maintaining efficiency and minimizing resource consumption.

Conclusion

Reducing waste in buffing operations requires a strategic approach. Optimizing system settings, using polish compound, implementing recycling systems, maintaining equipment, and training operators are essential steps. These strategies enhance the buffing process by improving efficiency and reducing the overuse of the final polishing compound. They also contribute to significant compound savings and environmental sustainability.

Adopting these practices ensures better results, lower costs, and a cleaner environment. Manufacturers can achieve a flawless final finish while maintaining operational excellence. By integrating these methods into their systems, businesses can maximize savings and improve their buffing outcomes.