Achieving a mirror-like shine elevates plastic surfaces to high-quality finishes, which are crucial for applications requiring clarity, such as lenses or transparent casings. Glossy finishes, recognized as category A grades by SPI, represent the benchmark for superior appearance. The process of in-line spraying and leveling is essential in achieving these results, as it ensures the consistent application and even distribution of polishing compound on plastic. By eliminating imperfections, these techniques provide practical solutions for those aiming to produce professional-grade finishes.

Key Takeaways

- In-line spraying uses machines to apply polishing compounds evenly.

- Leveling helps make surfaces smooth and shiny by fixing rough spots.

- Picking the right polishing compound for each plastic makes it clear and bright.

- Taking care of tools and surfaces keeps the polished look lasting longer.

- Good surface prep and steady application are key for great results.

What Is In-line Spraying and Leveling?

Defining In-line Spraying

In-line spraying refers to the automated application of polishing compound on plastic during a production process. This technique uses robotic or automatic spraying equipment to ensure consistent coverage across the material. The process minimizes human error and enhances efficiency, making it ideal for industries requiring high-quality finishes, such as automotive and electronics.

The spraying system operates by delivering the polishing compound in controlled amounts, ensuring uniform distribution. Electrostatic dust cleaning and solvent spraying often precede this step to prepare the surface for optimal adhesion. Following the application, UV curing and IR drying solidify the compound, creating a durable and glossy finish.

The Importance of Leveling for a Mirror-like Shine

Leveling plays a critical role in achieving a smooth and reflective surface. It involves the flow and settling of the polishing compound to eliminate uneven thickness and imperfections. Leveling agents, such as silicone-based additives, reduce surface tension, allowing the compound to spread evenly.

The leveling process typically occurs on a conveyor system, where the material rests for a few minutes to ensure uniform thickness. Factors like viscosity, temperature, and leveling time influence the final result. Proper leveling not only enhances the aesthetic appeal but also ensures the durability of the polished surface.

Tip: Silicone-based leveling agents are particularly effective for achieving a mirror-like shine due to their ability to migrate quickly to the surface.

Benefits of Using Polishing Compound on Plastic

Polishing compounds offer several advantages when applied to plastic surfaces:

- Aesthetic Improvement: These compounds remove scratches, oxidation, and other imperfections, resulting in a glossy and smooth finish.

- Extended Product Lifespan: By restoring worn surfaces, polishing compounds reduce the need for replacements, saving costs over time.

- Versatile Applications: Industries such as automotive, jewelry, and woodworking rely on polishing compounds to achieve precise and professional-grade finishes.

| Benefit | Description |

|---|---|

| Aesthetic Improvement | Polishing compounds remove imperfections, scratches, and oxidation, resulting in a glossy finish. |

| Extended Product Lifespan | They restore worn surfaces, reducing the need for replacements, which is cost-effective. |

| Industry Applications | Used in automotive, jewelry, electronics, and woodworking for achieving smooth, precise surfaces. |

Polishing compounds are particularly effective for materials like plexiglass, where clarity and shine are essential. When used correctly, they can transform dull surfaces into vibrant, polished finishes.

Essential Tools and Materials

Selecting the Right Polishing Compound

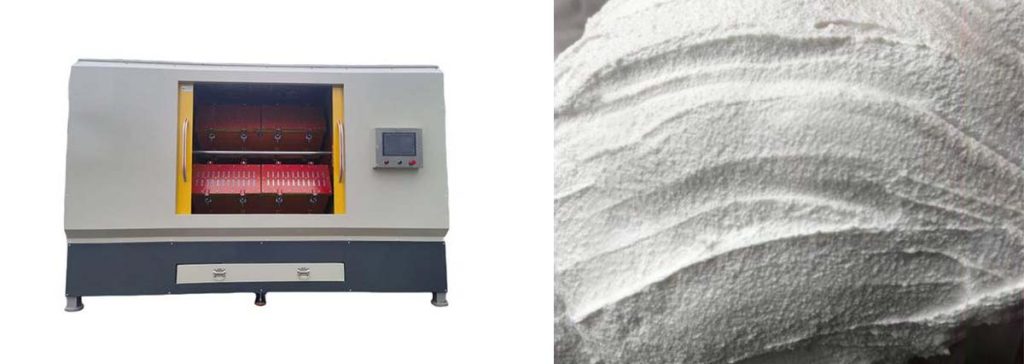

Choosing the correct polishing compound on plastic is critical for achieving a flawless finish. Different compounds cater to specific needs, depending on the material and desired outcome. For instance, Trowapast works well for hard surfaces like steel and brass, requiring extended polishing times. Ball polishing, on the other hand, offers a faster solution for materials such as aluminum and zinc. Powder compounds enhance abrasion performance, making them ideal for cleaning and roughening surfaces. Degreasing powders and pickling agents, like the Z1 agent, are effective for removing grease, oxidation, and rust from hard-to-reach areas.

When selecting a compound, consider the type of plastic being polished. For example, to polish plexiglass, use a compound designed for clarity and shine. This ensures the removal of water spots and yellowing, restoring the material’s original luster. Always apply compound evenly to avoid streaks or uneven finishes.

Tip: Test a small area before full application to ensure compatibility with the plastic surface.

Spraying Equipment for Consistent Application

Reliable spraying equipment ensures uniform application of the polishing compound on plastic. Modern advancements in thermal spraying technology have improved consistency and efficiency. For example, the ExactApply™ nozzle control system minimizes overapplication and drift, reducing waste and costs. Similarly, BoomTrac™ Pro 2 enhances accuracy by maintaining the boom’s position, achieving a 22% improvement in precision. Pressure recirculation systems keep chemicals in suspension, ensuring the equipment is always ready to spray.

Key practices for consistent application include maintaining a steady speed and distance during spraying. Conducting test sprays helps verify equipment functionality and adjust spray patterns. Diagnostic and monitoring units further enhance reliability by identifying potential issues before they affect the process.

Note: Regular maintenance of spraying equipment extends its lifespan and ensures optimal performance.

Tools for Surface Preparation and Leveling

Proper surface preparation is essential for a clean surface and a smooth finish. Tools like viscometers and rotational rheometers play a vital role in quality control. A viscometer measures the viscosity of the polishing compound, ensuring it flows evenly during application. Rotational rheometers simulate high shear rates, replicating the conditions of spraying to study structural regeneration.

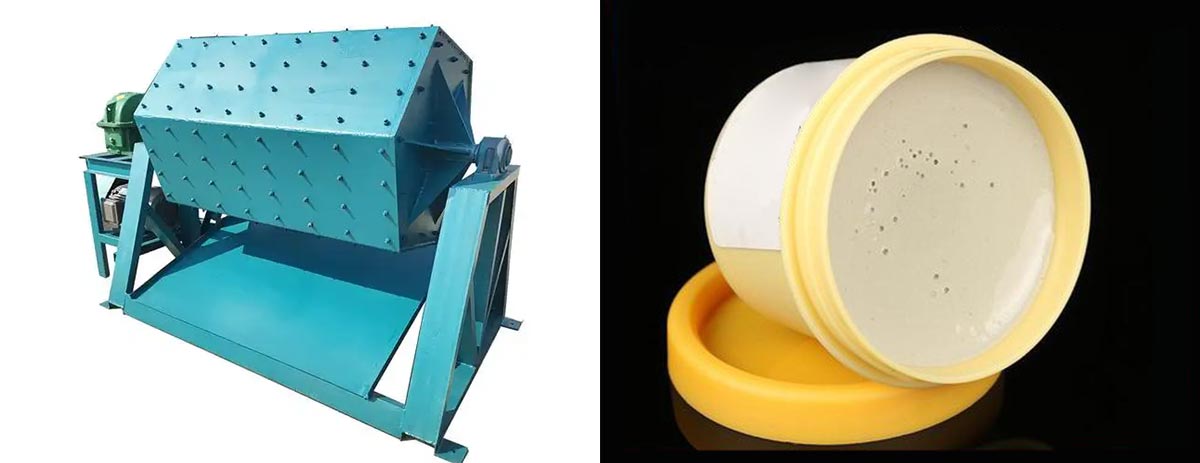

Additional tools for leveling include smoothers, gauge rakes, spiked rollers, and spiked shoes. Smoothers help spread the leveler evenly, while gauge rakes control the amount applied with adjustable precision. Spiked rollers break surface tension, ensuring uniform distribution, and spiked shoes allow movement across the surface without disturbing the leveler.

In production lines, instruments like the OSEE device assess surface cleanliness. By illuminating surfaces with UV light, the device detects contamination levels based on electron emissions. A clean surface emits more electrons, indicating proper preparation. For example, increasing water flow during rinsing can improve adhesion and reduce defects, as demonstrated in a recent case study.

Tip: Always clean the surface thoroughly before applying the compound to prevent adhesion issues and ensure a durable finish.

Step-by-Step Process for In-line Spraying and Leveling

Preparing the Plastic Surface for Polishing

Proper preparation of the plastic surface is the foundation for achieving a flawless finish. A clean surface ensures the polishing compound adheres effectively, reducing the risk of imperfections. The preparation process involves evaluating the material’s condition and selecting the appropriate techniques to address any surface issues.

| Technique | Description |

|---|---|

| Surface Preparation | Evaluating the material’s condition to select the appropriate abrasive for initial polishing steps. |

| Mechanical Polishing | Using fine abrasives to gradually smooth the surface while managing heat to prevent warping. |

| Challenges | Addressing issues like heat sensitivity and over-polishing that can damage the plastic surface. |

Mechanical polishing is particularly effective for removing oxidation, scratches, and other surface defects. However, care must be taken to avoid over-polishing, which can lead to warping or damage, especially on heat-sensitive materials like plexiglass. For best results, operators should use fine abrasives and monitor the process closely.

Tip: Always inspect the surface under proper lighting to identify water spots, yellowing, or other imperfections before proceeding.

Applying the Polishing Compound on Plastic

The application of the polishing compound on plastic requires precision and consistency. Different methods, such as buffing, lapping, and ultrasonic polishing, cater to specific needs and surface conditions. Each method offers unique advantages and performance metrics.

| Polishing Method | Description | Performance Metrics |

|---|---|---|

| Buffing | Involves using a buffing wheel and compound for a high-gloss finish. | Surface roughness, reflective quality |

| Lapping | Controlled abrasion for ultra-flat surfaces, often used in precision fields. | Roughness average (Ra) |

| Barrel Polishing | Kinetic method using abrasive media for deburring and surface preparation. | Finish precision, labor cost |

| Abrasive Flow Polishing | Uses a semi-solid medium to polish complex geometries. | Surface integrity, finish uniformity |

| Ultrasonic Polishing | High-frequency vibrations for delicate polishing tasks. | Dimensional accuracy, surface smoothness |

Buffing is one of the most common methods for applying polishing compounds. It delivers a high-gloss finish and enhances the reflective quality of the surface. For intricate geometries, abrasive flow polishing provides excellent results by reaching areas that are difficult to access with traditional methods.

Operators should apply compound evenly to avoid streaks or uneven finishes. Using the correct amount of compound is crucial to achieving a smooth and polished surface. Over-application can lead to clumping, while under-application may result in an incomplete finish.

Note: Test the polishing compound on a small area before full application to ensure compatibility with the plastic surface.

Techniques for Even Spraying

Even spraying is essential for uniform distribution of the polishing compound. Proper mixing and application techniques play a significant role in achieving a consistent spray pattern. Following these steps ensures optimal results:

- Use a power mixer to thoroughly mix the polishing compound and ensure uniform distribution of components.

- Refer to the manufacturer’s Product Data Sheet (PDS) for specific mixing instructions and ratios.

- Mix all components thoroughly to prevent clumping or settling.

- Combine components at the specified mix ratio and mix again to achieve uniformity.

- Allow for induction time if required, as indicated in the PDS.

- Thin the coating material as necessary, using only approved thinners, to achieve a consistent spray pattern.

Maintaining a steady speed and distance during spraying is equally important. Operators should conduct test sprays to verify equipment functionality and adjust spray patterns as needed. Regular maintenance of spraying equipment ensures consistent performance and extends its lifespan.

Tip: Always clean the spraying equipment after use to prevent clogging and ensure a smooth application in future projects.

Leveling Methods to Achieve a Smooth Finish

Achieving a smooth and mirror-like finish requires precise leveling techniques. These methods ensure the polishing compound spreads evenly across the surface, eliminating imperfections and enhancing the final appearance. The following steps outline effective leveling practices:

- Preparation: Begin by cleaning the surface thoroughly. A clean surface prevents dust or debris from interfering with the leveling process. This step is crucial for avoiding blemishes or uneven finishes.

- Grit Progression: Use sandpaper with progressively finer grits. Start with a coarse grit to remove significant imperfections, then transition to finer grits for a polished look. This gradual progression ensures a smooth and uniform surface.

- Polishing Compound Selection: Choose a compound specifically designed for plastics. This prevents cloudiness and ensures clarity, especially when working with materials like plexiglass.

- Safety Precautions: Always wear protective gear and follow safety guidelines when handling chemicals. Proper ventilation and protective equipment reduce risks during the leveling process.

For example, vapor polishing is an advanced technique that restores optical clarity in materials like polycarbonate lenses. By exposing the surface to chemical vapors, this method smooths out imperfections and creates a glossy finish. It is particularly effective for laboratory equipment and other high-precision instruments.

Tip: When leveling, maintain consistent pressure and motion to avoid uneven application. This ensures the compound spreads uniformly across the surface.

Post-Polishing Care for Long-lasting Results

Proper post-polishing care extends the lifespan of polished surfaces and maintains their shine. Neglecting maintenance can lead to the reappearance of imperfections, such as water spots or scratches. The following practices help preserve the polished finish:

- Regular cleaning prevents the buildup of dirt and grime. Use a soft, lint-free cloth to wipe the surface gently. Avoid abrasive cleaners that could damage the finish.

- Apply a protective coating to shield the surface from environmental factors. This layer reduces the risk of scratches and oxidation, keeping the surface looking new.

- Store polished items in a controlled environment. Excessive humidity or temperature fluctuations can affect the durability of the finish.

Consistent maintenance is essential for long-term results. Studies show that regular care significantly reduces the likelihood of damage. For instance, thorough cleaning and biofilm removal have been proven to extend the lifespan of polished surfaces. Regular maintenance therapy minimizes the progression of wear and tear, ensuring the surface retains its original luster.

Note: Avoid using harsh chemicals or abrasive tools during cleaning. These can strip away the protective layer and compromise the polished finish.

By following these care practices, polished surfaces like plexiglass can maintain their clarity and shine for years. Proper maintenance not only enhances the aesthetic appeal but also reduces the need for frequent re-polishing.

Tips for Professional Results

Ensuring Consistency in Application

Consistency in application is vital for achieving a professional finish. Operators should focus on maintaining uniform spray patterns and precise control over variables. Adjusting the nozzle flow rate, ground speed, and effective spray width ensures even distribution of the polishing compound.

| Variable | Description |

|---|---|

| Nozzle Flow Rate | Adjusting nozzle size and pressure affects the output significantly. |

| Ground Speed | Application rate decreases as ground speed increases; calibration must match actual speed. |

| Effective Spray Width | Wider spacing reduces application rate; adjustments may require nozzle changes or boom height changes. |

Operators should also verify equipment functionality before starting. Conducting test sprays helps identify potential issues and ensures the equipment is calibrated correctly. Regular maintenance of spraying tools prevents inconsistencies caused by wear and tear.

Tip: Always mix the polishing compound thoroughly to avoid clumping and ensure a smooth application.

Avoiding Common Mistakes During Spraying and Leveling

Mistakes during spraying and leveling can compromise the final finish. Common errors include uneven application, excessive film thickness, and improper surface preparation. To avoid these issues, operators should follow these guidelines:

- Maintain a steady speed and distance while spraying.

- Use the correct nozzle size and pressure settings for the material.

- Thoroughly clean the surface to remove dust, grease, or other contaminants.

Overlooking surface preparation often leads to adhesion problems. For materials like plexiglass, using a polishing compound designed for clarity prevents cloudiness and ensures a smooth finish. Operators should also avoid over-polishing, which can damage heat-sensitive plastics.

Note: Inspect the surface under proper lighting to identify imperfections before applying the compound.

Troubleshooting Issues for a Flawless Finish

When issues arise, troubleshooting ensures a flawless finish. Operators should identify symptoms, determine causes, and implement solutions. The table below outlines common problems and their remedies:

| Symptoms | Causes | Solutions |

|---|---|---|

| Bumps, rough textures | Excessive film thickness, improper grounding, incorrect spray distance, high KV settings. | Optimize Voltage Settings, Enhance Grounding. |

| Coating peels or flakes off easily | Contaminated substrate, incorrect curing time, ineffective pretreatment processes. | Thorough Cleaning, Appropriate Pretreatment. |

| Uneven, bumpy surface | High film thickness, incorrect spray gun settings, substrate issues. | Control Film Thickness, Optimize Gun Settings. |

Proactively addressing these issues ensures a polished and professional result. For example, optimizing spray gun settings and controlling film thickness can remove scratches and create a smooth, reflective surface.

Tip: Regularly monitor equipment performance to prevent recurring problems and maintain consistent results.

Conclusion

In-line spraying and leveling play a vital role in achieving a mirror-like shine on plastic surfaces. These techniques ensure consistent application and eliminate imperfections, resulting in professional-grade finishes. Proper tools, such as viscometers and spraying equipment, combined with effective preparation methods, enhance the quality of the final product.

Key Takeaway: Investing time in surface preparation and using the right polishing compound on plastic ensures durability and aesthetic appeal.

Readers can apply these methods confidently to transform dull plastic surfaces into polished, high-quality finishes. By following the outlined steps, they can achieve superior results that meet industry standards.