Mirror polishing creates a highly reflective surface by removing imperfections through a meticulous process. Regular polishing, on the other hand, focuses on achieving a smooth but less reflective finish. Understanding the differences between these techniques is essential for industries aiming to balance aesthetics and functionality.

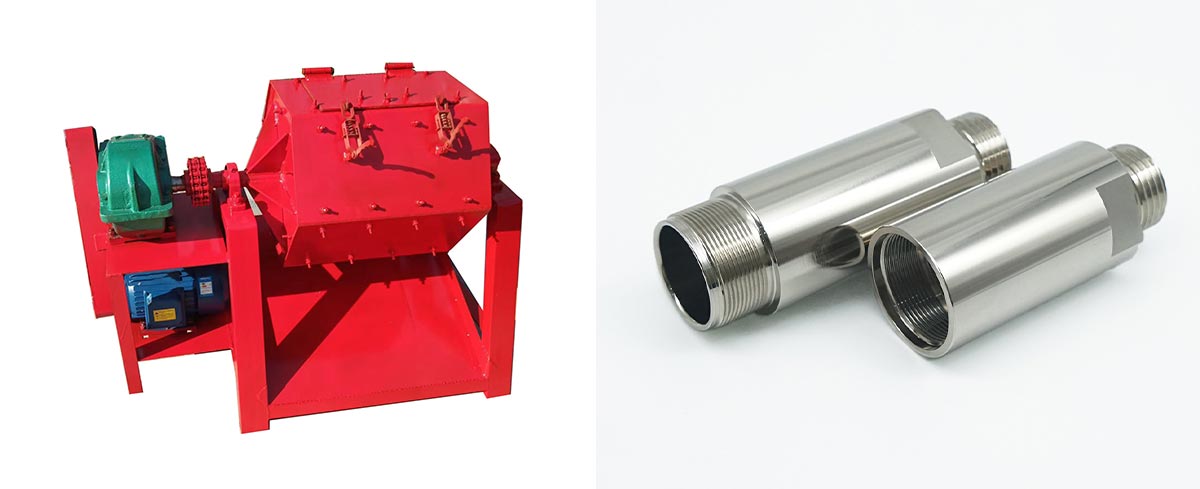

Mirror polishing enhances product appeal and durability. For instance, polished surfaces resist corrosion and reduce friction, extending the lifespan of mechanical components. In the automotive industry, polished wheels improve both visual appeal and fuel efficiency by reducing aerodynamic drag. Industrial polishing machines play a vital role in ensuring precise and consistent results for both finishes.

Key Takeaways

- Mirror polishing makes surfaces shiny and reflective, improving looks and strength.

- Regular polishing gives a smooth, dull finish that hides flaws, great for busy areas.

- Picking the right polishing method depends on the material, look, and use.

- Polishing machines are important for accurate and even results in both methods.

- Knowing how polishing works helps industries choose between beauty and usefulness.

Regular Polishing

Definition and Process

Regular polishing refers to a surface finishing technique that smooths materials by removing imperfections like scratches or uneven textures. This process typically involves abrasive materials or tools that gradually refine the surface. The goal is to achieve a uniform finish that enhances the material’s appearance and functionality.

For metals like stainless steel, regular polishing often uses abrasive pads or belts. These tools create a consistent texture while maintaining the material’s structural integrity. The process may vary depending on the desired finish, but it generally includes multiple stages, starting with coarse abrasives and progressing to finer ones. This method ensures a smooth surface suitable for various applications.

Characteristics of Brushed Polishing

Brushed polishing is a common type of regular polishing. It creates a matte or satin finish with fine, linear patterns. These patterns result from the controlled movement of abrasive tools across the surface. Unlike mirror polishing, brushed polishing does not aim for a reflective appearance. Instead, it focuses on achieving a subtle texture that hides minor imperfections.

Stainless steel often undergoes brushed polishing due to its durability and aesthetic appeal. The finish resists fingerprints and smudges, making it ideal for high-touch surfaces. Additionally, brushed polishing enhances the material’s resistance to wear and tear, ensuring long-lasting performance.

Common Applications

Regular polishing, including brushed polishing, serves various industries. Stainless steel appliances, such as refrigerators and ovens, frequently feature brushed finishes for their sleek yet practical appearance. Architectural elements like railings and panels also benefit from this technique, as it combines visual appeal with durability.

In the automotive sector, regular polishing improves the functionality and aesthetics of components like exhaust systems. Similarly, industrial equipment often undergoes this process to ensure smooth operation and extended lifespan. The versatility of regular polishing makes it a valuable technique across multiple fields.

Mirror Polishing

Definition and Process

Mirror polishing creates a surface with a high level of reflectivity and smoothness. This technique involves removing imperfections and achieving a flawless finish through a multi-step process. The initial stages use coarse abrasives to eliminate surface irregularities, followed by finer abrasives to refine the texture. The final step employs a soft cloth wheel combined with fine abrasive slurry to achieve a mirror-like finish with a roughness average (Ra) of less than 1 micron.

In optical manufacturing, advanced techniques like machine learning and sensor integration enhance the polishing process. These innovations improve surface quality and precision, ensuring the polished surface meets stringent requirements. Different types of cup wheels, varying in hardness and grain size, play a critical role in achieving the desired finish. Microscopic analysis of polished surfaces helps identify and address defects, ensuring optimal results.

Characteristics of Mirror Polishing

Mirror polishing stands out for its ability to produce a flawless, reflective surface. The finish, categorized as N12 in surface grade metrics, contrasts sharply with rougher grades like N1. This level of polish enhances both aesthetics and functionality. For example, polished surfaces reduce friction and wear, extending the service life of components such as gears.

The process involves meticulous attention to detail. A soft cloth wheel and fine abrasive slurry ensure the surface achieves a mirror-like appearance. This finish is particularly valuable in applications requiring precision and durability. In engineering, polished surfaces improve performance by minimizing surface irregularities, which can otherwise lead to defects or reduced efficiency.

Common Applications

Mirror polishing finds widespread use across industries. In automotive manufacturing, it enhances the aesthetic appeal of trim, wheels, and decorative elements. Polished surfaces also contribute to improved aerodynamics, reducing drag and boosting fuel efficiency.

In the glass polishing sector, mirror finishes are essential for applications in construction, electronics, and optical devices. The market for glass polishing is projected to grow from USD 1.2 billion in 2023 to USD 2.1 billion by 2032, driven by demand in these industries. Metal polishing also benefits from mirror finishes, particularly for jewelry and decorative hardware, where aesthetics and functionality are equally important.

Comparing Mirror Polishing and Regular Polishing

Surface Finish and Appearance

The surface finish and appearance of mirror polishing and regular polishing differ significantly. Mirror polishing produces a mirror-like surface with a high gloss and exceptional reflectivity. This no. 8 finish is smooth and flawless, making it ideal for applications requiring a luxurious and pristine look. In contrast, regular polishing, particularly brushed polishing, creates a satin or matte finish with a one-directional texture. This softer gloss retains a classic aesthetic while masking minor imperfections.

| Polishing Type | Surface Finish Description | Performance Characteristics |

|---|---|---|

| Brushed Polishing | Creates a softer, satin finish with a one-directional look. | Retains classic beauty, often used for decorative items. |

| Mirror Polishing | Results in a highly reflective surface that is easy to clean and maintain. | Removes surface defects, preferred for restoring damaged surfaces. |

Mirror polishing enhances the visual appeal of materials, making them appear more refined and elegant. The high gloss of a mirror finish also improves functionality by reducing surface friction and wear. On the other hand, brushed polishing offers a more subdued appearance, which is practical for applications where durability and a subtle texture are prioritized.

Techniques and Tools (Including Industrial Polishing Machines)

Both mirror polishing and regular polishing rely on specific techniques and tools to achieve their respective finishes. The polishing process for mirror finishes involves multiple stages, starting with roughing to remove surface defects. Mini roto-orbital sanders are commonly used during this stage, with specific disc types selected to minimize visible marks. Polishing follows, utilizing quick-cut abrasive pastes and tools like wool berets and polishing sponges. Brightening is the final step, where microfiber cloths and precise RPM ranges ensure uniformity and a high gloss.

For brushed polishing, the techniques focus on creating a consistent satin texture. Abrasive belts or pads are used to achieve the desired linear patterns. Industrial polishing machines play a crucial role in both methods, offering precision and efficiency. These machines ensure consistent results, whether producing a no. 8 finish or a brushed surface.

Additional steps, such as applying a protective wax coat, enhance the durability and luster of the polished surface. The condition of abrasive compounds and the speed of polishers are critical factors in achieving optimal results. Proper maintenance of tools and adherence to recommended techniques ensure the longevity of the polished surface.

Durability and Maintenance

The durability and maintenance requirements of mirror polishing and regular polishing vary based on the finish. Mirror finishes, with their smooth and reflective surfaces, are easier to clean and maintain. The high gloss resists dirt and grime, making it suitable for applications where hygiene is essential. However, the flawless nature of a mirror-like surface makes it more susceptible to visible scratches, requiring careful handling.

Brushed finishes, on the other hand, are more forgiving when it comes to wear and tear. The satin texture hides minor scratches and imperfections, making it ideal for high-traffic areas or surfaces exposed to frequent use. Maintenance involves regular cleaning to prevent the buildup of dirt, but the finish does not require the same level of meticulous care as a mirror finish.

Both finishes benefit from protective coatings that enhance their durability. Industrial polishing machines equipped with advanced features can apply these coatings efficiently, ensuring long-lasting performance. Choosing the right finish depends on the specific application and the balance between aesthetics and practicality.

Cost and Time Considerations

Cost and time play crucial roles in determining the suitability of mirror polishing or regular polishing for specific applications. Each method involves distinct processes and tools, which directly impact expenses and production timelines.

Mirror polishing requires a multi-step process that includes roughing, polishing, and brightening stages. These steps demand precision and specialized tools, such as soft cloth wheels and fine abrasive slurries. The meticulous nature of this process increases both the time and cost involved. For instance, achieving a flawless mirror finish on a 50-mm diameter, biconvex N-BK7 lens involves significant fabrication costs, especially during prototyping. However, the high gloss and durability of the final product often justify the investment for industries prioritizing aesthetics and performance.

Regular polishing, particularly brushed polishing, offers a more cost-effective alternative. This method uses abrasive belts or pads to create a satin finish with a linear texture. The process is less time-intensive, making it ideal for high-volume production. For example, when comparing two aspheric lens designs, the N-SF57 glass option proved €12,500 more cost-efficient for producing 5,000 units. This highlights the economic advantage of regular polishing for large-scale manufacturing.

Time efficiency also depends on the tools and technologies employed. Advanced software applications, such as PanDao, optimize optical designs in real time. These tools reduce fabrication risks and streamline the polishing process, saving valuable time. Industrial polishing machines further enhance efficiency by ensuring consistent results across multiple units. While mirror polishing demands more time due to its intricate steps, regular polishing benefits from simpler techniques that accelerate production.

Choosing the Right Polishing Method

Factors to Consider

Selecting the appropriate polishing method depends on several critical factors. Each factor ensures the process aligns with the material’s properties and the desired outcome. Key considerations include:

- Material Type: Different materials, such as metals, glass, or plastics, require specific polishing techniques to achieve optimal results.

- Expected Results: The required finish quality, whether a mirror-like surface or a brushed texture, determines the method.

- Surface Inspection: Evaluating the surface condition helps identify imperfections and select the right approach.

- Production Volume and Cost: High-volume production may favor cost-effective methods, while low-volume, high-precision tasks might justify more intricate processes.

- Equipment Selection: Machines must match the material’s properties and the desired finish. Modular and rigid frames enhance durability, while well-assembled parts ensure consistent performance.

Tip: Always consider safety regulations and industry standards when choosing a polishing method. Compliance ensures both quality and worker safety.

When to Use Brushed Polishing?

Brushed polishing is ideal for applications prioritizing durability and practicality over high reflectivity. This method suits scenarios where a satin or matte finish enhances functionality and aesthetics. Common use cases include:

- High-Traffic Surfaces: Brushed finishes resist fingerprints and scratches, making them perfect for appliances, railings, and panels.

- Industrial Equipment: The satin texture hides minor imperfections, ensuring long-lasting performance in demanding environments.

- Cost-Effective Production: Brushed polishing requires fewer steps, making it suitable for large-scale manufacturing where speed and efficiency are critical.

This method works best for materials like stainless steel, where the linear patterns add a subtle yet professional appearance.

When to Use Mirror Polishing?

Mirror polishing excels in applications requiring a flawless, reflective surface. This method enhances both aesthetics and functionality, making it the preferred choice for:

- Luxury Products: Jewelry, decorative hardware, and high-end automotive components benefit from the high gloss and pristine appearance.

- Precision Engineering: Polished surfaces reduce friction and wear, improving the performance of gears and other mechanical parts.

- Hygienic Environments: The smooth surface resists dirt and grime, making it ideal for medical devices and food processing equipment.

The meticulous process of mirror polishing ensures a finish that meets stringent quality standards. While it demands more time and resources, the results often justify the investment for industries prioritizing aesthetics and performance.

Conclusion

Mirror polishing and regular polishing differ in surface finish, techniques, and applications. Mirror polishing creates a reflective, flawless surface, while regular polishing offers a satin or matte texture. Each method serves specific purposes, from enhancing aesthetics to improving durability.

Key Insight: Selecting the right polishing method depends on material type, desired finish, and application requirements.

Industrial polishing machines ensure precision and consistency in both processes. Their advanced features streamline production, making them indispensable for achieving high-quality results. By understanding these differences, industries can make informed decisions to meet their unique needs effectively.