Plastic manufacturing generates significant waste, with approximately 350 million tonnes produced globally each year. Only 9% of this waste undergoes recycling, while half ends up in landfills. Mismanaged plastic waste, accounting for 20%, often leaks into natural water bodies, posing environmental risks. Reducing waste in this industry is essential for sustainability and resource conservation.

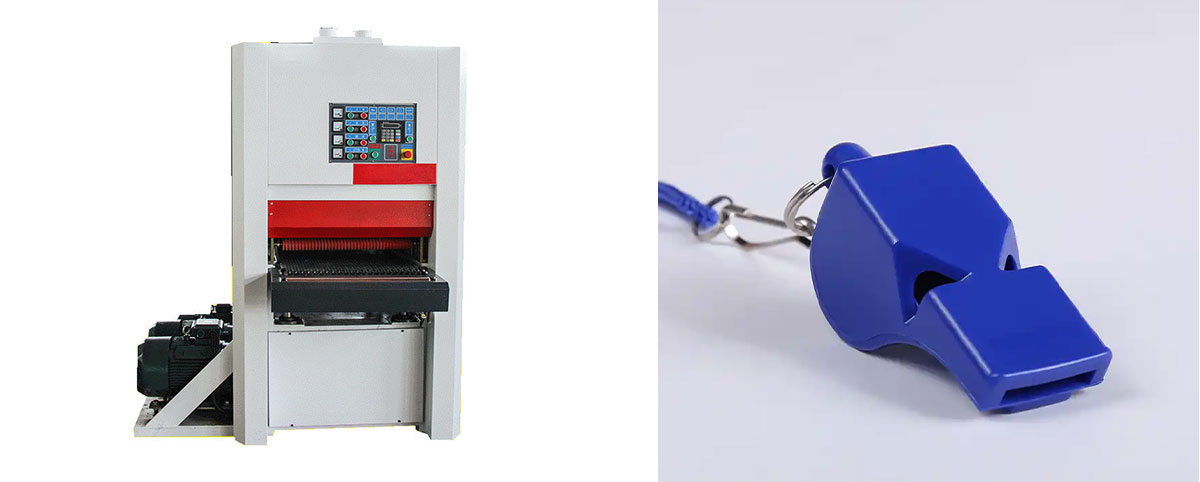

Automation plays a pivotal role in addressing these challenges. It improves productivity by enabling real-time monitoring and flexible scheduling. These advancements streamline production cycles and enhance efficiency. Plastic polishing equipment, when integrated with automation, ensures precise processes that minimize waste and optimize output. This combination supports manufacturers in achieving both environmental and operational goals.

Key Takeaways

- Plastic polishing equipment cuts waste by removing material carefully and keeping products strong.

- Machines with automation save time by working faster and smoother, helping companies meet needs quickly.

- Using IoT tech lets factories watch processes live and fix problems fast.

- Buying good plastic polishing equipment saves money over time with less energy use and fewer repairs.

- Teaching workers to use automated tools helps them work better and make fewer mistakes.

How Plastic Polishing Equipment Reduces Waste?

Precision and Consistency in Polishing

Reducing Material Waste Through Precise Polishing

Plastic polishing equipment ensures high precision during the polishing process. Machines equipped with advanced technology remove only the necessary material, leaving the rest intact. This approach minimizes unnecessary waste and preserves the integrity of the product. By focusing on precision, manufacturers achieve reduced waste while maintaining the desired finish.

Ensuring Consistent Quality to Minimize Defective Products

Consistency plays a vital role in reducing waste. Automatic polishing machines deliver uniform results across all products. This reduces the likelihood of defects, which often lead to discarded items. Consistent quality ensures that fewer resources are wasted, contributing to both sustainability and cost savings.

Advanced Techniques for Waste Reduction

Minimizing Excess Material Removal During Polishing

Modern plastic polishing machine uses innovative techniques to avoid excessive material removal. These machines operate with programmed settings that optimize the polishing process. By removing only what is necessary, manufacturers reduce waste and improve efficiency.

Recycling and Reusing Waste Materials in the Process

Recycling is another effective strategy for reducing waste. Many manufacturers now collect and reuse the byproducts generated during polishing. These materials are processed and reintegrated into production, creating a closed-loop system. This practice supports sustainability by reducing the need for new raw materials.

Environmental and Cost Advantages

Lower Raw Material Consumption and Energy Usage

Reducing raw material consumption directly impacts costs and environmental sustainability. The table below highlights the benefits of lower material usage:

| Benefit | Explanation |

|---|---|

| Improved Financial Health | Increases cash flow and reduces debt, allowing for reinvestment in growth. |

| Increased Profit Margins | Directly linked to cost reduction initiatives. |

| Reduced Resource Consumption | Leads to less waste and lower overall production costs. |

Efficient machines also consume less energy, further reducing operational costs and environmental impact.

Supporting Sustainability Goals in Manufacturing

Plastic polishing equipment aligns with sustainability goals by minimizing waste and conserving resources. Manufacturers adopting these machines contribute to a greener future. This approach not only benefits the environment but also enhances their reputation as eco-conscious businesses.

Boosting Productivity with Plastic Polishing Equipment

Faster and More Efficient Processes

Reducing Downtime with Automated Systems

Automation significantly enhances productivity by minimizing downtime. Plastic polishing equipment equipped with automated systems operates continuously, reducing interruptions caused by manual interventions. These machines streamline workflows, ensuring that production remains consistent and efficient. By automating repetitive tasks, manufacturers can focus on other critical areas, further improving overall productivity.

Accelerating Production Cycles for Higher Output

Modern plastic polishing machine is designed to handle high-demand environments. The increased speed allows manufacturers to complete production cycles faster, meeting tight deadlines without compromising quality. This capability not only boosts output but also reduces costs associated with extended production times. Faster cycles mean businesses can meet market demands more effectively, enhancing their competitive edge.

Enhanced Accuracy and Reliability

Leveraging Robotics for Flawless Finishes

Robotics plays a crucial role in achieving high-quality finishes during polishing. These systems offer several advantages:

- Increased stability and accuracy ensure consistent results.

- Higher production rates meet the demands of large-scale operations.

- Reduced human error minimizes defects and waste.

- Improved safety protects workers from hazardous tasks.

- Enhanced precision guarantees flawless finishes every time.

Polishing robots eliminate variations caused by manual labor, ensuring uniformity across all products. Their ability to operate continuously without fatigue further improves efficiency and productivity.

Reducing Human Error in Polishing Tasks

Human error often leads to inconsistencies and defects. Automated polishing systems address this issue by standardizing processes. Machines programmed with precise settings deliver consistent results, reducing waste and ensuring improved precision. This approach not only enhances productivity but also supports sustainability by minimizing resource usage.

Integration with Smart Manufacturing

IoT-Enabled Monitoring for Real-Time Adjustments

The integration of IoT technology into plastic polishing equipment allows real-time monitoring of operations. Sensors collect data on performance, enabling immediate adjustments to optimize processes. This capability improves efficiency and reduces downtime, ensuring that machines operate at peak performance. IoT-driven insights also help manufacturers identify potential issues before they escalate, further enhancing productivity.

AI-Driven Optimization for Continuous Improvement

Artificial intelligence takes automation to the next level by enabling continuous improvement. AI algorithms analyze data to identify patterns and suggest optimizations. These insights help manufacturers refine their processes, achieving lower energy consumption and higher output. By leveraging AI, businesses can maintain consistent quality while reducing costs and supporting sustainability goals.

Key Technologies Driving Plastic Polishing Equipment

Robotics and AI

Adaptive Systems for Complex Polishing Tasks

Robotics and AI have revolutionized plastic polishing equipment by enabling adaptive systems that handle intricate tasks with precision. Robots equipped with sensors and advanced algorithms autonomously perform polishing operations, ensuring consistent results. Collaborative robots (cobots) enhance safety and productivity by working alongside human operators. Sophisticated control systems further improve reliability by allowing real-time adjustments during polishing. These advancements reduce waste and increase efficiency, making them indispensable in modern manufacturing.

| Advancement Type | Description |

|---|---|

| Collaborative Robots (Cobots) | Cobots enhance safety and productivity by working alongside humans in polishing applications. |

| Sophisticated Control Systems | These systems improve precision and reliability, enabling real-time adjustments during polishing. |

| AI and Machine Learning | These technologies allow robots to adapt and optimize polishing parameters based on real-time data. |

Self-Learning Algorithms for Improved Performance

AI-driven self-learning algorithms analyze variables during polishing to optimize parameters in real time. Machines equipped with these algorithms adapt to different surfaces and materials, ensuring flawless finishes. This technology not only enhances productivity but also supports sustainability by minimizing resource consumption and reducing costs.

IoT and Real-Time Monitoring

Data-Driven Insights for Better Process Control

IoT integration in plastic polishing equipment provides real-time data for better process control. Sensors monitor machine performance, enabling manufacturers to make immediate adjustments. This data-driven approach improves efficiency and reduces downtime, ensuring machines operate at peak performance.

Predictive Maintenance to Minimize Downtime

Predictive maintenance, powered by IoT, identifies potential issues before they cause disruptions. By analyzing machine data, manufacturers can schedule maintenance proactively, avoiding unexpected breakdowns. This approach enhances productivity and extends the lifespan of equipment, contributing to long-term sustainability.

Advanced Materials and Tools

High-Performance Abrasives for Superior Results

High-performance abrasives play a crucial role in achieving superior polishing results. These materials offer a wide range of applications, from mold polishing to handling various surfaces. Their high processing efficiency allows multiple pieces to be polished simultaneously, reducing costs and improving productivity.

- Fluidity and viscoelasticity adapt to different surfaces.

- Even dispersion of abrasive particles ensures uniform results.

- Strong cutting effects and fast processing speeds enhance efficiency.

Durable Equipment for Long-Term Efficiency

Durable materials used in plastic polishing machine ensure long-term efficiency and reliability. The machine requires minimal maintenance, reducing operational costs. The stability and extended service life align with sustainability goals, making them a valuable investment for manufacturers.

Practical Strategies for Implementing Plastic Polishing Equipment

Selecting the Right Plastic Polishing Equipment

Key Factors: Size, Capacity, and Compatibility

Choosing the right plastic polishing equipment requires careful evaluation of size, capacity, and compatibility. Manufacturers must assess their production needs to determine the appropriate machine size. Smaller machines suit limited production, while larger ones handle high-volume operations. Capacity plays a crucial role in meeting production demands efficiently. Compatibility with existing systems ensures seamless integration, reducing potential disruptions.

Balancing Cost with Long-Term Benefits

Investing in plastic polishing equipment involves balancing initial costs with long-term benefits. High-quality machines may require a larger upfront investment but offer significant advantages. These include lower energy consumption, reduced maintenance expenses, and long-term cost reduction. Evaluating the return on investment (ROI) helps manufacturers make informed decisions. A well-chosen machine not only reduces costs but also enhances productivity and sustainability.

Optimizing Processes for Efficiency

Training Staff to Work with Automated Systems

Proper training ensures that staff can operate automated polishing systems effectively. Employees must understand the technology and its functions to maximize productivity. Training programs should focus on machine operation, troubleshooting, and maintenance. Skilled operators reduce errors, improve efficiency, and contribute to a reduction in labor costs.

Regular Maintenance for Consistent Performance

Routine maintenance keeps machines running smoothly and prevents unexpected breakdowns. Scheduled inspections identify potential issues early, ensuring consistent performance. Maintenance also extends the lifespan of equipment, reducing costs over time. Well-maintained machines deliver reliable results, supporting sustainability and productivity goals.

Planning for Scalability

Modular Systems for Future Upgrades

Modular systems provide flexibility for future scalability. These systems allow manufacturers to add or upgrade components as production demands increase. This approach minimizes the need for complete replacements, saving costs and resources. Modular designs also adapt to new technology, ensuring long-term efficiency.

Preparing for Increased Production Demands

Planning for scalability involves anticipating future production needs. Manufacturers should evaluate ROI and invest in equipment that supports growth. Machines with advanced features, such as higher speed and automation, meet increased demands effectively. This preparation ensures that businesses remain competitive while maintaining sustainability and productivity.

Conclusion

Plastic polishing equipment has proven to be a game-changer in reducing waste and enhancing productivity. By delivering precision and consistency, these machines minimize material loss and ensure high-quality output. Automation further amplifies these benefits by streamlining operations and optimizing resource use. This approach not only supports sustainability but also positions manufacturers for long-term success in the competitive plastic industry.

Investing in advanced polishing solutions offers significant economic and environmental advantages. Emerging trends, such as IoT integration and AI-driven optimization, enable predictive maintenance and real-time process adjustments. Industries like automotive and electronics increasingly demand high-quality polished components, driving the need for innovative technologies. Manufacturers who adopt these solutions can achieve greater efficiency, reduced costs, and a stronger commitment to sustainability.

🌟 Tip: Exploring the latest advancements in polishing machine automation can help businesses stay ahead in a rapidly evolving market.