The products of traditional compound and polish often contain harsh chemicals that harm the environment and human health. These substances contribute to water pollution and generate non-biodegradable waste, which lingers for decades. Workers exposed to these compounds face risks such as respiratory issues and skin irritation. Sustainable alternatives offer a promising solution by reducing toxic waste and promoting green chemistry. These safer alternatives not only protect ecosystems but also improve workplace safety. Industries adopting eco-friendly practices can minimize their environmental footprint while fostering innovation.

Key Takeaways

- Regular polishing products hurt nature and people’s health. Using eco-friendly options can make things safer.

- Plant-based scrubs, like walnut shells, are natural and break down easily. They cut waste and help reuse resources.

- Recycled items, like glass and plastic, save money and reduce trash. This helps the planet and follows rules.

- Water-based and biodegradable compounds are better for workers and nature. They avoid strong chemicals and harmful leftovers.

- Checking environmental data often helps industries see their progress. Learning about new ideas keeps them eco-friendly and legal.

The Problem with Traditional Compound and Polish

Environmental Impact

Non-Biodegradable Waste and Its Long-Term Effects

Traditional compound and polish products often contain synthetic materials that do not break down easily. These materials accumulate in landfills, contributing to the growing problem of non-biodegradable waste. Over time, this waste can leach harmful chemicals into the soil, disrupting ecosystems and harming wildlife. The persistence of these materials in the environment creates long-term challenges for waste management and ecological balance.

Chemical Runoff and Water Pollution

The use of traditional polishing compounds frequently results in chemical runoff. During cleaning or disposal, these substances can enter water systems, contaminating rivers, lakes, and oceans. This pollution harms aquatic life and disrupts ecosystems. Regulations like the National Emission Standards for Hazardous Air Pollutants (NESHAP) aim to address such issues by requiring industries to adopt practices that minimize emissions and control hazardous pollutants effectively.

Health and Safety Concerns

Worker Exposure to Toxic Substances

Workers in industries using traditional compound and polish products face significant health risks. Many of these compounds contain hazardous chemicals such as cadmium and chromium. Prolonged exposure can lead to skin irritation, chemical burns, and even long-term health conditions. Employers must implement strict safety measures to protect workers, but these measures often increase operational costs.

Respiratory Risks from Airborne Particles

The polishing process generates fine particles that become airborne. Workers inhaling these particles may develop respiratory issues, including chronic conditions like asthma. The risk is particularly high in poorly ventilated environments. Protective equipment can reduce exposure, but it does not eliminate the problem entirely.

Economic and Regulatory Pressures

Rising Costs of Compliance with Environmental Laws

Industries using traditional compound and polish products face increasing costs to comply with environmental regulations. For example, NESHAP mandates the use of wetting agents and specialized equipment to control emissions. These requirements raise operational expenses, making it harder for businesses to remain competitive.

Challenges in Managing Industrial Waste

Managing waste from traditional polishing compounds presents logistical and financial challenges. Companies must invest in proper disposal methods to avoid penalties and environmental damage. The table below highlights some of the economic pressures industries face:

| Economic Pressure | Description |

|---|---|

| Regulatory Hurdles | Stringent regulations can limit market expansion and increase costs. |

| Supply Chain Disruptions | Vulnerability to global supply chain issues affects product availability. |

| Competitive Landscape | Increasing competition requires differentiation to maintain market position. |

These pressures emphasize the need for industries to explore sustainable alternatives that reduce costs and environmental impact.

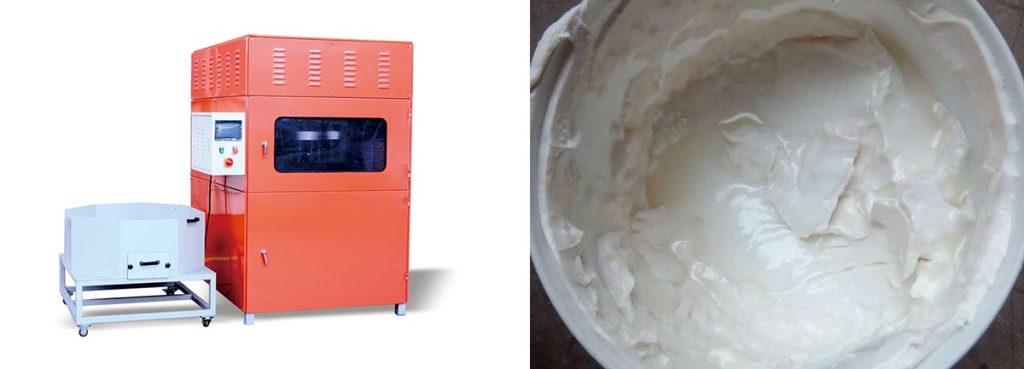

Eco-Friendly Alternatives in Polishing Compounds

Plant-Based Abrasives

Examples Like Walnut Shells and Corn Cobs

Plant-based abrasives offer a sustainable solution for polishing needs. Materials such as walnut shells and corn cobs serve as excellent examples of renewable resources. These abrasives are derived from agricultural byproducts, making them both cost-effective and environmentally friendly. Industries can use these materials to replace synthetic abrasives, reducing reliance on non-renewable resources.

Benefits of Renewable and Biodegradable Materials

Plant-based abrasives decompose naturally, leaving no harmful residues. Their renewable nature supports the circular economy by minimizing waste and promoting resource efficiency. These eco-friendly alternatives also reduce the carbon footprint of manufacturing processes. By adopting plant-based solvents and abrasives, industries can align with green replacements that prioritize sustainability.

Recycled and Repurposed Materials

Use of Recycled Glass and Plastic

Recycled materials, such as glass and plastic, provide another effective alternative for polishing compounds. These materials are repurposed from industrial and consumer waste, transforming discarded items into valuable resources. For instance, crushed glass can serve as a polishing medium, offering durability and precision.

Reducing Industrial Waste Through Repurposing

Using recycled materials contributes to the circular economy by diverting waste from landfills. This approach reduces the environmental impact of production processes while conserving raw materials. Industries adopting these eco-friendly practices can lower costs and meet regulatory requirements more effectively. Recycled materials also demonstrate the potential of bio-based products in creating sustainable solutions.

Biodegradable and Water-Based Compounds

Introduction to Biodegradable Polymers

Biodegradable polymers represent a breakthrough in green replacements for traditional compounds. These materials break down naturally over time, leaving no toxic residues. They are often derived from bio-based products, such as plant oils or algae, making them a key component of eco-friendly alternatives.

Advantages of Water-Based Eco-Friendly Solvents

Water-based solvents offer a safer and more sustainable option for polishing applications. These compounds eliminate the need for harsh chemicals, reducing risks to both workers and the environment. Their non-toxic nature ensures compatibility with various surfaces, making them versatile and effective. By transitioning to water-based and biodegradable compounds, industries can embrace eco-friendly solutions that align with modern sustainability goals.

Innovations in Green Chemistry

Nanotechnology for Sustainable Polishing

Nanotechnology has revolutionized green chemistry by introducing innovative solutions for polishing applications. This advanced technology uses nanoparticles to achieve precise and efficient polishing. These particles, often smaller than 100 nanometers, provide a smoother finish with minimal material waste. Industries benefit from this approach by reducing the need for harsh chemicals and conserving resources.

Nanoparticles derived from sustainable raw materials, such as silica or titanium dioxide, enhance the eco-friendliness of this method. These materials are renewable and biodegradable, aligning with the principles of green chemistry. Additionally, nanotechnology reduces energy consumption during the polishing process. Its efficiency minimizes the environmental impact, making it a preferred choice for industries seeking sustainable practices.

Researchers continue to explore new ways to integrate nanotechnology with sustainable raw materials. This combination holds the potential to replace traditional compounds entirely, paving the way for a greener future.

Bio-Based Chemicals and Algae-Derived Compounds

Bio-based chemicals represent another breakthrough in green chemistry. These chemicals are derived from sustainable raw materials, including plant oils, agricultural waste, and algae. Unlike traditional compounds, bio-based chemicals decompose naturally, leaving no harmful residues. Their production process also generates fewer emissions, contributing to a cleaner environment.

Algae-derived compounds have gained attention for their versatility and sustainability. Algae grow rapidly and require minimal resources, making them an ideal source of raw materials. Scientists extract oils and polymers from algae to create biodegradable polishing compounds. These compounds perform effectively while reducing reliance on petroleum-based products.

Industries adopting bio-based chemicals benefit from improved sustainability and compliance with environmental regulations. By utilizing algae-derived compounds, they can further reduce their carbon footprint. This innovation exemplifies how green chemistry transforms industrial practices, promoting the use of sustainable raw materials for a healthier planet.

How to Transition to Eco-Friendly Practices?

Evaluating Current Processes

Conducting Environmental Audits

Industries must begin their transition by assessing their current processes. Conducting environmental audits helps identify the environmental impact of existing polishing methods. These audits evaluate waste generation, energy consumption, and chemical usage. By analyzing this data, businesses can pinpoint inefficiencies and areas of concern. This step provides a clear baseline for implementing sustainable practices.

Identifying Areas for Improvement

After completing an audit, industries should focus on areas that require immediate attention. For example, replacing harmful chemicals with sustainable alternatives to 2-butoxyethanol or ammonia can significantly reduce environmental harm. Identifying outdated equipment or processes that consume excessive energy also helps streamline operations. This evaluation ensures that businesses prioritize changes with the greatest impact.

Selecting the Right Eco-Friendly Solvent and Materials

Assessing Performance and Compatibility

Choosing the right eco-friendly solvent requires careful consideration. Businesses must test the performance of sustainable cleaning solutions to ensure they meet industry standards. Compatibility with existing equipment and materials is equally important. For instance, water-based cleaning products often work well with a variety of surfaces, making them a versatile choice. Testing ensures that the transition does not compromise quality or efficiency.

Partnering with Sustainable Suppliers

Collaborating with sustainable suppliers offers numerous benefits:

- Enhanced product quality.

- Reduced environmental impact.

- Promotion of social responsibility and ethical sourcing.

- Mitigation of supply chain risks.

- Access to innovation and cutting-edge solutions.

Sustainable suppliers are often at the forefront of innovation, developing new technologies, materials, and processes that are environmentally friendly and socially responsible.

These partnerships also provide stability. Suppliers with strong risk management practices help businesses avoid disruptions caused by natural disasters or regulatory changes. This reliability ensures a consistent supply chain, which is essential for maintaining operations.

Implementing Changes

Training Employees on New Methods

Employees play a crucial role in adopting sustainable practices. Training programs should educate workers on using eco-friendly solvents and sustainable cleaning solutions effectively. Hands-on workshops and clear instructions ensure that employees feel confident in applying new techniques. This step minimizes errors and promotes a smooth transition.

Phased Adoption to Minimize Disruption

Industries should implement changes gradually to avoid operational disruptions. A phased approach allows businesses to test new materials and methods on a smaller scale before full adoption. For example, introducing sustainable alternatives to 2-butoxyethanol in one production line helps identify potential challenges. This strategy reduces risks and ensures a seamless shift to greener practices.

Monitoring and Adapting

Tracking Environmental and Economic Outcomes

Industries adopting eco-friendly practices must monitor their progress to ensure long-term success. Tracking specific metrics helps businesses evaluate the effectiveness of their sustainable initiatives.

- Climate-related metrics: Companies should assess assets vulnerable to climate risks, such as revenue from oil extraction or investments in climate adaptation. These metrics highlight areas requiring immediate attention.

- Water management metrics: Monitoring water consumption, intensity, and recycled water usage is essential. Industries operating in high-water stress areas benefit significantly from tracking effluents and improving water efficiency.

- Waste management metrics: Businesses should evaluate the types of waste produced, disposal costs, and disposal rates. This data helps refine waste management strategies and reduce environmental impact.

- Health and safety metrics: Recording work-related injuries, illnesses, and lost time incidents ensures workplace safety. These metrics also help companies comply with health regulations.

Regularly analyzing these metrics allows industries to identify trends and make data-driven decisions. This proactive approach ensures that eco-friendly practices remain effective and economically viable.

Staying Updated on Innovations and Regulations

The sustainability landscape evolves rapidly, requiring industries to stay informed about new developments. Innovations in green chemistry, such as algae-derived compounds or nanotechnology, continue to transform polishing processes. Businesses must actively explore these advancements to maintain a competitive edge.

Regulatory changes also play a critical role in shaping industrial practices. Governments frequently update environmental laws to address emerging challenges. Companies must monitor these updates to ensure compliance and avoid penalties. Subscribing to industry newsletters, attending conferences, and collaborating with research institutions are effective ways to stay informed.

Adapting to new innovations and regulations demonstrates a commitment to sustainability. This adaptability not only enhances environmental performance but also strengthens a company’s reputation as a responsible industry leader.

Conclusion

Adopting sustainable alternatives to traditional polishing compounds is essential for reducing long-term environmental damage. Industries benefit from biodegradable chemicals, recyclable feedstocks, and low VOC solutions that minimize ecological harm. Environmentally friendly cleaning products and biodegradable solvents serve as effective hazardous solvent substitutes, offering zero HAP content while maintaining performance. Rising consumer demand for green products and global expansion opportunities further highlight the importance of eco-friendly practices. By embracing natural solvents and innovative technologies, businesses can reduce waste, conserve resources, and achieve a greener future. Proactive steps today ensure a healthier planet for generations to come.