Buffing and polishing machines play a critical role in industries such as automotive, aerospace, and metalworking. These machines ensure smooth finishes, enhance product durability, and meet the rising demand for high-quality outputs. Their adoption continues to grow due to advancements in technology and increased versatility. Top buffing and polishing machine manufacturers drive innovation by integrating automation for precision, reducing waste through sustainable practices, and offering customized solutions for specific industry needs. In 2025, these trends are expected to further enhance productivity and revolutionize manufacturing processes.

Key Takeaways

- New ideas are important. Pick makers using green and smart tech to save energy and help the planet.

- Strong machines last longer. Choose ones built with tough materials for heavy use on different surfaces.

- Good help matters. Go for makers with great support, repairs, and advice after buying.

- Trust is key. Check customer opinions and company fame to pick reliable brands.

- Custom options are useful. Find makers who adjust machines to fit your work needs better.

Criteria for Selecting Top Buffing and Polishing Machine Manufacturers

Innovation and Technology

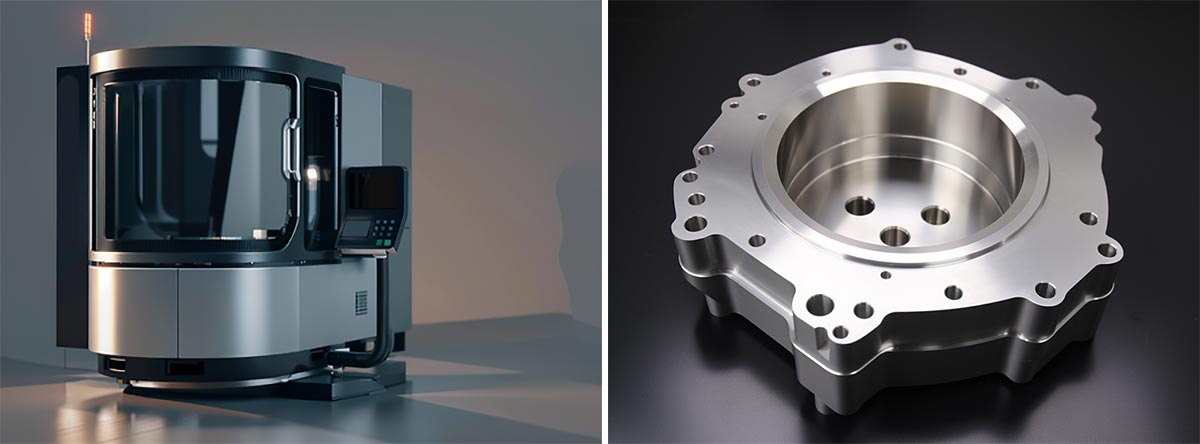

Innovation drives the evolution of buffing and polishing machines, ensuring they meet modern industry demands. Leading manufacturers integrate cutting-edge technologies to enhance precision and efficiency. For instance, automation allows machines to perform tasks with minimal human intervention, reducing labor costs and improving accuracy. Sustainability has also become a priority, with eco-friendly polishing compounds and waste reduction methods minimizing environmental impact. Customization further sets top manufacturers apart, as they tailor solutions to meet the unique needs of industries like automotive and aerospace.

| Key Advancement | Description |

|---|---|

| Automation | Integration of robotics and computerized controls for higher precision and reduced labor costs. |

| Sustainability | Adoption of eco-friendly polishing compounds and waste minimization to reduce carbon footprint. |

| Customization | Tailored solutions for different industries, enhancing partnerships and productivity. |

Technologies such as the forced rotation dual action polisher and random orbital polisher exemplify these advancements. These tools provide superior control and versatility, making them ideal for heavy paint correction and achieving a flawless finish.

Product Quality and Durability

Durability and quality are non-negotiable when selecting buffing and polishing machine manufacturers. Machines must withstand rigorous use while maintaining consistent performance. High-quality materials and robust construction ensure longevity, even under demanding conditions. Adaptability is another critical factor. Machines should accommodate various materials and finishes, from delicate paint surfaces to heavy-duty metal polishing.

Manufacturers offering gear driven orbital polishers and free spinning random orbital polishers excel in this area. These tools effectively remove scratches and imperfections while delivering a smooth finish. Their versatility makes them suitable for diverse applications, from automotive paint finishing to industrial metalwork.

Customer Support and After-Sales Service

Customer support plays a pivotal role in ensuring long-term satisfaction. Top manufacturers prioritize after-sales services, offering preventive maintenance, remote support, and personalized solutions. These services not only enhance efficiency but also build trust and loyalty among customers.

- Faster and more personalized services meet rising customer expectations.

- Data analytics enable tailored service offerings, improving customer experience.

- Feedback loops allow manufacturers to refine services, demonstrating their commitment to customer needs.

For instance, a cordless polisher backed by excellent after-sales support ensures seamless operation, even in challenging scenarios. This approach fosters strong relationships and encourages positive reviews, solidifying the manufacturer’s reputation.

Industry Reputation and Customer Reviews

Industry reputation and customer reviews significantly impact the success of buffing and polishing machine manufacturers. A strong reputation builds trust, while positive reviews attract new customers and reinforce loyalty among existing ones. In 2025, manufacturers must prioritize these aspects to remain competitive in the market.

How Reviews Influence Purchasing Decisions?

Customer reviews play a critical role in shaping purchasing behavior. Studies reveal the following insights:

- 93% of customers read online reviews before making a purchase.

- 97% of participants consider reviews a key factor in their buying decisions.

- 86% of people hesitate to engage with companies that have numerous negative reviews.

These statistics highlight the importance of maintaining a positive online presence. Manufacturers must actively monitor and respond to reviews to address concerns and demonstrate their commitment to customer satisfaction.

Factors Shaping Industry Reputation

Several elements contribute to a manufacturer’s reputation. The table below outlines key factors and their impact:

| Reputation Score Factor | Insights |

|---|---|

| Listing and Directory Presence | Accurate and complete business listings enhance visibility and credibility. |

| Online Reviews | High-quality reviews and prompt responses build trust and attract customers. |

| Social Media Presence | Active engagement on platforms fosters brand awareness and customer loyalty. |

| Surveys | Feedback from surveys helps identify trends and improve services. |

| Customer Experience Management | Effective strategies ensure superior service quality and customer retention. |

By excelling in these areas, buffing and polishing machine manufacturers can strengthen their reputation and gain a competitive edge. A proactive approach to managing reviews and enhancing customer experience ensures long-term success in the industry.

Top Buffing and Polishing Machine Manufacturers in 2025

Adam’s Polishes

Key Products

Adam’s Polishes offers a range of high-quality tools and products for the paint correction process. Popular items include Adam’s Patriot Wax, priced at $69.99, and the Adam’s 4 Bottle Show Bag, available for $19.99. These products receive consistent praise in customer reviews for their effectiveness and value.

Technical Features

Adam’s Polishes stands out for its forced rotation dual action polisher, which delivers high efficiency and precision. This tool is ideal for heavy paint correction and ensures a flawless finish. The company also emphasizes durability, with products designed to withstand rigorous use. Customers frequently highlight the brand’s outstanding customer service and product quality, which outperform competitors like Wolfgang and Pinnacle.

Application Scenarios

Adam’s Polishes caters to both professional detailers and DIY enthusiasts. Their tools are easy to use and suitable for various tasks, including removing scratches, achieving a smooth finishing step, and restoring paint surfaces. These products excel in automotive applications, where achieving a mirror-like finish is crucial.

Chemical Guys

Key Products

Chemical Guys offers a diverse selection of buffing pads and polishing compounds. Their pads, designed for different grades, address deep scratches and light swirls effectively. These products are essential for professionals and DIY users aiming for a perfect finish.

Technical Features

The forced rotation dual action polisher from Chemical Guys integrates advanced technology for superior performance. Their polishing compounds are recognized for cutting power and restoring paint to its original luster. The durability of their pads ensures they maintain shape even after multiple uses, making them a high quality tool for long-term applications.

Application Scenarios

Chemical Guys’ products are versatile, catering to automotive, marine, and industrial needs. Their random orbital polisher is particularly effective for the paint correction process, delivering consistent results. Professionals and hobbyists alike rely on these tools for achieving a flawless finish in various finishing steps.

Batoca

Key Products

Batoca specializes in cordless polishers and gear driven orbital polishers. These tools are designed for convenience and efficiency, making them a favorite among users seeking mobility and precision.

Technical Features

Batoca’s forced rotation dual action polisher combines power and control, ensuring optimal results. Their free spinning random orbital polisher offers versatility, making it suitable for delicate paint surfaces and heavy-duty tasks. The polishing pad design enhances performance, providing a smooth and even finish.

Application Scenarios

Batoca’s tools are ideal for automotive paint correction and industrial polishing tasks. Their cordless polisher is particularly useful for on-the-go applications, offering flexibility without compromising performance. These products are easy to use and deliver high efficiency, making them a reliable choice for professionals and DIY enthusiasts.

Avid Power

Key Products

Avid Power offers a range of innovative tools designed for precision and durability. Their standout product, the Avid Power Tire Inflator Air Compressor, has gained recognition for its exceptional performance. Customers have praised its lightweight design and ability to inflate a tire from 25 PSI to 35 PSI in just over a minute. The product also features accurate PSI readings with an error margin of only 1 PSI. Users value its inflation target setting, which prevents overinflation. However, some reviews mention its noise level, measured at 89.5dB, as a drawback.

Technical Features

Avid Power integrates advanced technology into its machines to enhance efficiency and usability. Key innovations introduced in 2025 include:

- AGILE & DYNAMIC: Designed for outdoor enthusiasts, excelling in activities like hunting and fishing.

- VERSATEC™ GUNNEL: A proprietary design enabling various accessory mounts.

- ROD/GUN BOX: Dual-purpose storage with quick access.

- MARINE GRADE ELECTRICAL SYSTEM: Features waterproof components and circuit breaker protection.

These features ensure reliability and adaptability, making Avid Power’s tools suitable for diverse applications. Their forced rotation dual action polisher exemplifies this innovation, delivering precise results for heavy-duty tasks.

Application Scenarios

Avid Power’s machines cater to professionals and hobbyists alike. Their random orbital polisher is ideal for automotive paint correction, ensuring a smooth finish during the final finishing step. The gear driven orbital polisher offers versatility, making it suitable for delicate surfaces and industrial applications. These tools excel in vehicle detailing, where achieving a flawless finish is essential.

Worx

Key Products

Worx specializes in versatile and user-friendly tools for polishing and buffing. Their cordless random orbital polisher stands out for its portability and ease of use. This tool is perfect for users seeking mobility without compromising performance. Worx also offers a range of polishing pads designed for durability and consistent results.

Technical Features

Worx machines incorporate cutting-edge technology to enhance performance. Their forced rotation dual action polisher combines power and precision, making it suitable for heavy paint correction. The random orbital polisher ensures even application, reducing the risk of swirl marks. Worx prioritizes durability, with products built to withstand rigorous use.

Application Scenarios

Worx tools are ideal for automotive and industrial applications. Their random orbital polisher excels in paint correction, delivering a flawless finish. Professionals rely on these tools for tasks requiring precision and efficiency. Worx products are also popular among DIY enthusiasts for their user-friendly design and reliable performance.

Comparison Table of Buffing and Polishing Machine Manufacturers

Key Features Compared

When evaluating buffing and polishing machine manufacturers, several features stand out. These include application scenarios, technical parameters, and the pros and cons of each brand. The table below highlights these aspects for a clearer comparison:

| Feature | Details |

|---|---|

| Application Scenarios | Suitable for plumbing hardware, automotive spare parts, and valve manufacturing. |

| Technical Parameters | Lightweight designs, available in electric and air-powered models. |

| Pros | Competitive pricing, high quality, easy operation, and labor-saving benefits. |

| Cons | Limited details on specific machine capabilities and high initial investment costs. |

Each manufacturer offers unique advantages. For instance, lightweight designs improve usability, while electric and air-powered options provide flexibility. However, some machines require skilled operation, which may increase training costs.

Pricing and Value

Pricing plays a crucial role in determining the value of buffing and polishing machines. Manufacturers like Adam’s Polishes and Chemical Guys offer premium products with advanced features, often at higher price points. These tools deliver exceptional performance, making them ideal for professional use. On the other hand, brands like Batoca and Worx provide cost-effective solutions without compromising quality.

High initial investment costs can deter some buyers. However, the long-term benefits, such as improved surface finish quality and reduced labor requirements, justify the expense. Machines designed for automotive paint correction, for example, ensure a flawless finish, enhancing the overall value of the product.

Customer Support Ratings

Customer support significantly impacts the user experience. Top manufacturers prioritize after-sales services, including maintenance, troubleshooting, and personalized assistance. Adam’s Polishes and Avid Power excel in this area, offering prompt and reliable support.

Brands with strong customer support receive higher ratings and positive reviews. This fosters trust and loyalty among users. For instance, a manufacturer providing detailed guidance on using a random orbital polisher for paint correction ensures customer satisfaction. Conversely, limited support can lead to frustration and negative feedback.

Tip: Always consider customer support when selecting a manufacturer. Reliable assistance can save time and prevent costly downtime.

Conclusion

The top buffing and polishing machine manufacturers in 2025 demonstrate excellence through innovation, durability, and customer support. Each brand offers unique features tailored to specific applications, from automotive paint correction to industrial polishing. Selecting the right machine depends on understanding industry requirements and matching them with the manufacturer’s strengths. Exploring customer feedback and a detailed review of product capabilities ensures an informed decision. These manufacturers provide reliable solutions for professionals and enthusiasts seeking high-quality finishes.

Note: Researching further details and reviews will help identify the best fit for your needs.