Polishing compound, or what is polishing compound, is a specialized material designed to clean, smooth, and enhance surfaces. It plays a crucial role in refining textures by removing imperfections and creating a polished finish. The compound is widely used across industries to improve the functionality and visual appeal of materials. For example, it helps achieve a flawless surface on metals, wood, and even glass. By addressing scratches and unevenness, polishing compound ensures surfaces not only look better but also perform more effectively in their intended applications.

Key Takeaways

- Polishing compound is essential for achieving smooth, refined surfaces by removing imperfections like scratches and uneven textures.

- The compound enhances the aesthetic appeal of materials, providing a glossy, professional finish that adds value to products in industries like automotive and jewelry.

- Selecting the right polishing compound based on material (metal, wood, glass) and purpose (cutting, finishing) is crucial for optimal results.

- In automotive applications, polishing compound restores vehicle paint, enhancing appearance and protecting against damage.

- Woodworkers and furniture makers use polishing compounds to refine surfaces and enhance the natural grain, ensuring high-quality finishes.

- Proper handling and safety precautions are important when using polishing compound to avoid damage and ensure effective results.

What Is Polishing Compound?

Importance of Surface Enhancement

Smoothing and Refining Surfaces

Polishing compound plays a vital role in achieving smooth and refined surfaces. Its abrasive properties help eliminate minor imperfections, such as scratches or uneven textures, from various materials. By carefully applying the compound during the polishing process, users can transform rough surfaces into sleek, uniform finishes. This step is essential in industries like metalworking, where precision and surface quality significantly impact the final product.

“In the metalworking world, polishing plays a major role. Polishing makes a product aesthetically pleasing. One of the most important elements in the polishing process is polishing compounds.” – Industry Professionals

The ability to refine surfaces ensures that materials not only look better but also function more effectively. For example, smoother surfaces reduce friction in mechanical components, enhancing their performance and durability.

Enhancing Aesthetic Appeal

Polishing compound enhances the visual appeal of materials by creating a high-quality finish. It removes dullness and restores the natural luster of surfaces, making them appear polished and professional. This is particularly important in industries like jewelry-making and automotive detailing, where aesthetics play a crucial role.

“Metal polishing compound is a specialized substance designed to enhance the appearance and luster of metal surfaces.” – Manufacturers

Whether used on metals, wood, or glass, polishing compound ensures that surfaces achieve a glossy, mirror-like appearance. This transformation not only improves the material’s look but also adds value to the finished product.

Functionality of Polishing Compound

Removing Imperfections

Polishing compound excels at removing imperfections from surfaces. The compound effectively addresses issues like light scratches, watermarks, and oxidation, which can detract from a material’s appearance and functionality. The compound’s fine abrasive particles work to gently level out uneven areas, leaving behind a flawless surface.

This functionality is especially valuable in automotive applications, where maintaining a vehicle’s paintwork is essential. By using a buffing compound, car owners can restore their vehicle’s shine while protecting it from further damage.

Achieving a Glossy Finish

Achieving a glossy finish is one of the primary goals of using a polishing compound. The compound’s unique formulation allows it to create a smooth, reflective surface that enhances the material’s overall appearance. This glossy effect is highly sought after in industries like furniture-making and metal fabrication, where a polished look signifies quality and craftsmanship.

“If you’ve ever worked with metal, you know the importance of the polishing stage to make a product that is both functional and aesthetically pleasing.” – Industry Professionals

By incorporating a buffing compound into the polishing process, users can achieve a durable and natural-looking shine. This step not only improves the material’s aesthetics but also protects it from wear and tear, ensuring long-lasting results.

Types of Polishing Compounds

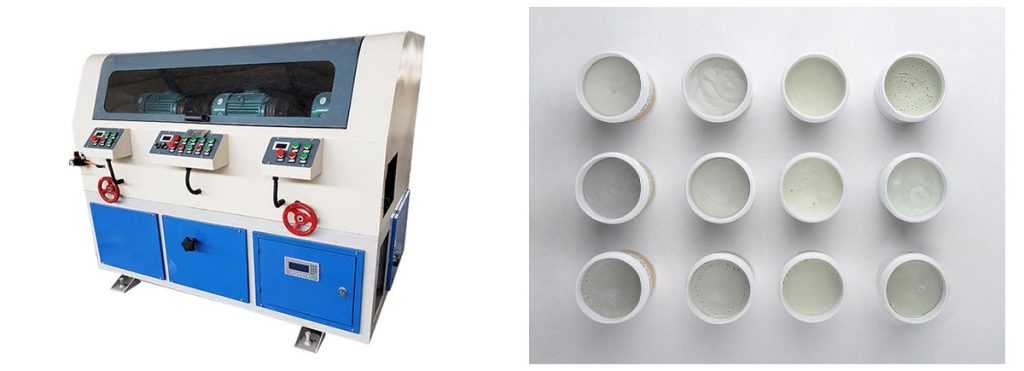

Polishing compounds come in various formulations, each tailored to specific materials and purposes. Understanding these distinctions helps users select the right product for their needs, ensuring optimal results.

Based on Material

Polishing compounds are often categorized by the type of material they are designed to work with. Each material requires a unique formulation to achieve the desired finish without causing damage.

- Metal Polishing Compounds: These compounds are ideal for metals like stainless steel, chrome, and aluminum. For instance, the Black compound contains emery minerals, making it effective for removing scratches, pits, and oxidation from metallic surfaces. It also provides a polished, mirror-like finish, saving time and effort during the buffing process.

- Wood Polishing Compounds: Designed for woodworking projects, these compounds smooth out imperfections and enhance the natural grain of the wood. They are commonly used in furniture-making to achieve a refined and glossy appearance.

- Glass Polishing Compounds: These non-abrasive compounds, such as those used in conjunction with tools like the Gforce Max, are perfect for removing light scratches and achieving distortion-free clarity on glass surfaces.

- Automotive Polishing Compounds: Automotive-grade compounds address paint imperfections, such as scratches and oxidation. Products like Mothers® Professional Heavy Duty Rubbing Compound are specifically formulated to remove sanding marks and restore factory-applied finishes.

Each material demands a specific type of polishing compound to ensure the surface is treated effectively without compromising its integrity.

Based on Purpose

Polishing compounds can also be classified based on their intended purpose. This categorization focuses on the level of abrasiveness and the desired outcome.

- Cutting Compounds: These are coarser and designed for heavy-duty tasks, such as removing deep scratches or oxidation. For example, RUPES D-A COARSE offers fast defect removal and works efficiently on various paint types.

- Finishing Compounds: These compounds are finer and used for achieving a smooth, glossy finish. They are ideal for the final stages of polishing, where precision and aesthetics are crucial. The Stainless Steel Polishing Compound, for instance, is perfect for minor scratch removal and creating a mirror-like surface.

- All-Purpose Compounds: Some products, like versatile polishing compounds, cater to a wide range of applications. These are suitable for addressing light scratches, water stains, and other minor imperfections across different surfaces.

Selecting the right type of polishing compound based on its purpose ensures that users achieve the desired results efficiently. For heavy restoration work, cutting compounds are essential, while finishing compounds excel in delivering a professional-grade shine.

Common Uses of Polishing Compound

Polishing compounds serve a wide range of purposes across various industries. Their versatility and effectiveness make them indispensable for achieving smooth, polished surfaces and enhancing the appearance of materials.

Automotive Applications

In the automotive industry, a polishing compound is essential for maintaining and restoring vehicle surfaces. It removes small scratches, oxidation, and watermarks from paint, leaving a smooth and glossy finish. Car enthusiasts and professionals often rely on a buffing compound to achieve a showroom-quality shine. This process not only enhances the vehicle’s appearance but also protects the paint from further damage.

“The polishing compound is quite harsh in nature and used to provide a newly shine on your vehicles. With this compound you can polish your vehicle to leave a shining and smoothing effect.” – Industry Insights

Automotive-grade polishing compounds, such as those designed for heavy-duty tasks, are particularly effective for addressing imperfections on factory-applied finishes. They ensure that vehicles maintain their aesthetic appeal while extending the lifespan of the paintwork.

Woodworking and Furniture

Polishing compounds play a crucial role in woodworking and furniture-making. They smooth out imperfections, enhance the natural grain of the wood, and create a high-quality finish. Woodworkers often use a buffing compound to refine intricate carvings and prevent damage to delicate patterns. Properly polished tools and surfaces improve precision and ensure a professional result.

“Polishing compounds are crucial for maintaining the accessories of wood carving tools, especially when carving intricate patterns. Properly polished tools prevent damage to the workpiece and enhance carving precision.” – Craftsmen’s Guide

Furniture makers also rely on polishing compounds to achieve a glossy, refined appearance. This step in the polishing process adds value to the finished product, making it more appealing to customers.

Jewelry and Precious Metals

In the jewelry industry, polishing compounds are indispensable for achieving a mirror-like finish on precious metals. Jewelers use specialized buffing compounds, such as red rouge, to bring out the highest shine possible on materials like gold and silver. These compounds are specifically formulated to smooth and shine soft, non-ferrous metals without cutting into the surface.

“Red polishing compound is often used by professional jewelers to bring out the highest shine polish possible on precious metals like silver and gold.” – Jewelry Experts

A single buffing compound, such as white rouge, can transform a dull, oxidized piece of jewelry into a radiant, scratch-free masterpiece. This meticulous polishing process ensures that jewelry pieces achieve a high-quality finish, enhancing their beauty and value.

Other Industrial and Household Uses

Polishing compounds serve a vital role in both industrial and household settings, offering versatility and effectiveness for various applications. Their ability to enhance surfaces makes them indispensable across different environments.

Industrial Applications

In industrial sectors, polishing compounds are essential for achieving precise and high-quality finishes. Industries such as automotive, aerospace, and electronics rely heavily on these compounds to refine metal surfaces. For example, metal polishing ensures components meet strict quality standards while maintaining their visual appeal. The compounds also help prevent oxidation and tarnish, which can compromise the durability of metal parts.

“Polishing compounds are crucial materials in achieving functional and aesthetically pleasing metal products in industrial applications.” – Industry Insights

Buffing compounds used in manufacturing often come in different forms and abrasiveness levels. Coarser compounds remove deep scratches and imperfections, while finer ones create a smooth, reflective finish. This adaptability ensures that industrial processes achieve the desired results efficiently.

Household Applications

In households, polishing compounds focus more on enhancing the appearance and preserving the quality of everyday items. Homeowners use a buffing compound to restore the shine of metallic objects like cutlery, fixtures, and decorative pieces. These compounds also work well on glass and wood surfaces, making them versatile tools for home maintenance.

“Buffing compounds cater to both industrial and household applications based on specific needs and desired outcomes.” – Experts in Surface Care

Household-grade polishing compounds are generally less abrasive, ensuring they are safe for delicate surfaces. They help maintain the aesthetic appeal of items while extending their lifespan. For instance, a buffing compound can transform dull, scratched surfaces into polished, mirror-like finishes, adding value to household objects.

Safety Considerations

Proper handling of polishing compounds is crucial in both industrial and household settings. Some compounds contain abrasive or chemical components that require careful application. Users should wear protective gloves and ensure adequate ventilation during use. Reading the safety instructions on the product label guarantees secure and effective results.

Polishing compounds, whether used in large-scale industries or small household tasks, remain indispensable for achieving smooth, polished surfaces. Their adaptability and effectiveness make them valuable tools for enhancing both functionality and aesthetics.

Conclusion

Polishing compound plays a vital role in refining and enhancing surfaces across various industries. Understanding what is polishing compound and its types ensures users can select the most suitable option for their specific needs. Each buffing compound addresses unique requirements, whether for smoothing imperfections, achieving a glossy finish, or restoring materials like metal, wood, or glass. Choosing the right polishing compound significantly impacts the final result, improving both appearance and functionality. By exploring how to choose the right polishing compound, individuals can achieve professional-grade finishes and extend the lifespan of their materials.